Why energy & environment plants choose Maintmaster

Maximise output without raising emissions

Use Maintmaster CMMS to manage maintenance, safety, and compliance, or Maintmaster OEE to monitor conversion efficiency and asset performance in real time. Each system delivers measurable results on its own, yet together they provide one clear view of uptime, reliability, and environmental impact. Start with either system or connect them to uncover stoppages, eliminate efficiency losses, and prevent emission risks, turning maintenance data into sustainable performance and cost control.

01.

Before

Expensive downtime and dangerous days

In waste-to-energy, biofuel, utilities, and recycling, downtime is costly and dangerous. You don't know the real cause of inefficiencies while paper-based inspection logs and siloed systems make compliance harder.

02.

Action

Keep performance high always

Measure plant efficiency in real time with standardised maintenance and HSE procedures including digital checklists and traceable approvals. Trigger instant alerts when performance deviates from target levels, whether it’s reduced throughput, overheating equipment, or rising emissions.

03.

Results

Drive continuous improvement

Keep your plant safe, compliant, and moving with less downtime and complete traceability. Powered by connected AI insights and workflows from one source of truth that help your teams act faster, prevent failures, and drive ongoing improvement,

- 35 less unplanned downtime with CMMS

- 15 improvement in OEE within the first six months

- 25 faster audit preparation thanks to built-in compliance tracking

- 20 reduction in spare part costs with smarter Stockroom management

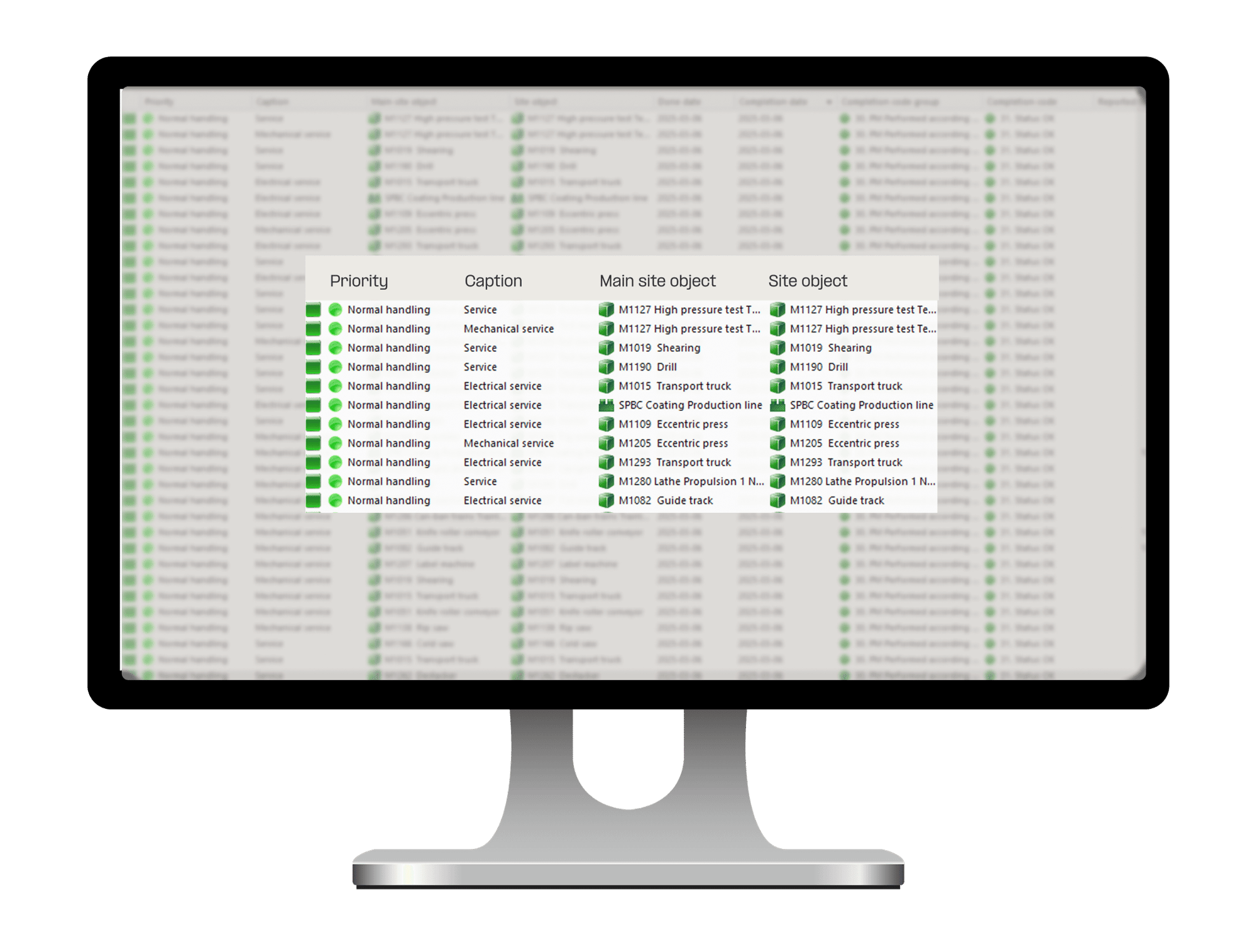

Key features and capabilities

Get digital HSE and permits always ready

Create step-by-step checklists and approval flows for hazardous work. Automatically log every task, inspection, and lockout.

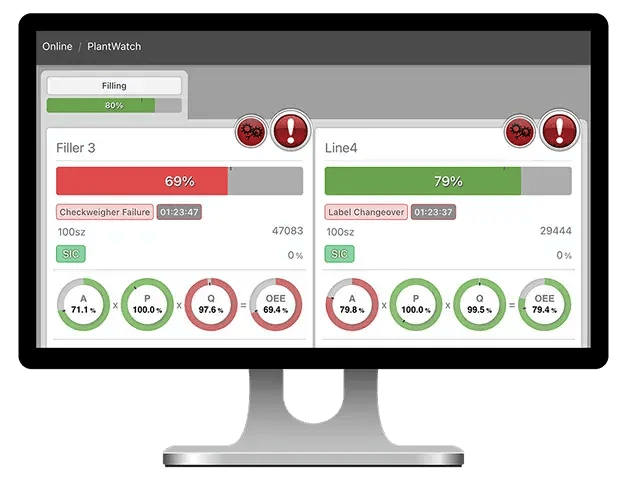

Measure OEE for energy conversion and waste

Track availability, throughput, and output quality adapted for combustion, anaerobic digestion, recycling, or electrical conversion.

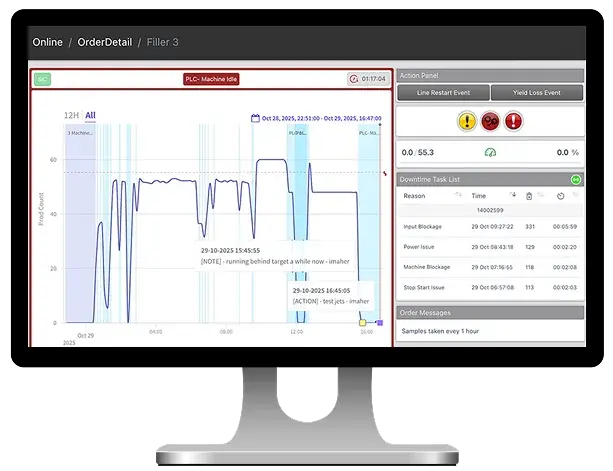

Monitor and stay predictive

Connect the system direct to your PLC to get accurate data and trigger maintenance jobs automatically before asset or environmental failure occurs.

Better together — CMMS + OEE

Use each system alone or connect them for maintenance reliability and production performance that power each other. Trigger work orders in the CMMS automatically when the OEE identifies a problem and see a completed repair reflected in the OEE dashboards. Start with one system and connect when you're ready for full visibility.

The old way

- Paper logs and reactive fixes

- Last-minute audit preparation

- Manual HSE routines and permits

- Energy loss hard to diagnose

The new way

- Real-time data triggers and digital workflows

- Reports ready in seconds

- Standardised, traceable approvals

- OEE visibility reveals root causes fast

Choose CMMS for control.

Choose OEE for visibility.

Combine both for excellence.

frequently asked questions

- What makes Maintmaster suitable for energy and environmental plants?

-

Maintmaster standardises safety procedures, ensures traceable inspection routines, and connects maintenance with real-time performance data to minimise risk and downtime.

- How does Maintmaster help keep plants safe and compliant?

-

By replacing paper-based logs with digital checklists, approval flows, and traceable permits, MaintMaster ensures every task meets HSE and regulatory standards. Compliance data is logged automatically, making audits faster and more reliable.

- Is Maintmaster compatible with existing systems and PLC data?

-

Yes. MaintMaster connects directly to PLCs and existing infrastructure, enabling accurate, real-time monitoring and automatic job creation when performance drops or environmental thresholds are exceeded.

- Can I start with one system and expand later?

-

Absolutely. Both CMMS and OEE work as standalone products, but together they form a connected ecosystem. Start with what you need, maintenance control or production visibility—and connect both when you're ready for total operational insight.

- What’s the main goal of using Maintmaster in energy and environment operations?

-

To maximise output without increasing emissions — powered by safer operations, smarter decisions, and connected data.