Why food & beverage companies choose Maintmaster

stay compliant and keep production running.

Use Maintmaster CMMS to manage maintenance, hygiene and documentation, or Maintmaster OEE to track output, performance, and quality in real time. Powerful alone and better together, they give you instant results and one overview of your complete operations. Start with one system or connect them for one safe and transparent food and beverage process.

01.

Before

Manual safety checks, siloed data, audit stress

Food and beverage plants often rely on paper logs, disconnected tools, and last-minute scrambling to gather safety and maintenance history for audits. Root cause analysis becomes slow, teams miss cleaning checks, and plants lose money and time on unneccessary waste and downtime.

02.

Action

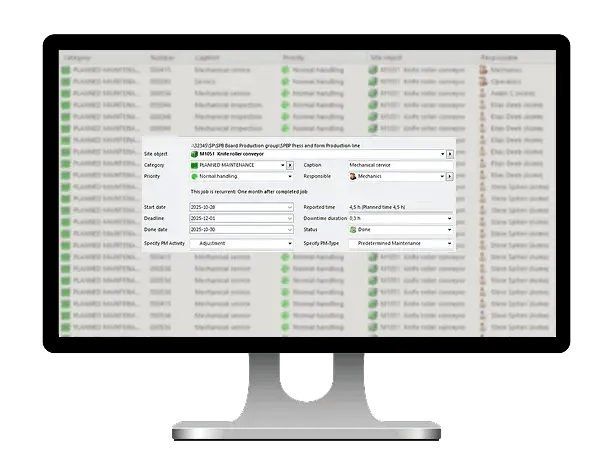

Trace maintenance and production fully

Digitise maintenance and production for full traceability. Standardise every safety, cleaning, and calibration task automatically with real-time visibility into product quality, downtime, and efficiency to make faster decisions based on real data.

03.

Results

Make continous improvement your standard

Food and beverage manufacturers get safe and efficient operations with audit-ready traceability powered by built-in compliance workflows that remove risk and manual work. Trace every inspection, task, and permit automatically and get smoother production that makes continous improvement your new standard.

- 35 less unplanned downtime with CMMS

- 15 improvement in OEE within the first six months

- 25 faster audit preparation thanks to built-in compliance tracking

- 20 reduction in spare part costs with smarter Stockroom management

Maintmaster at 30 production lines at Snellman

“Before MaintMaster, there was a lot of searching around in different binders and phone calls to find this kind of information.” - Torbjörn Byggmästar, Maintenance manager

Read the full story here

Key features and capabilities

Stay ready, pass every audit

Comply automatically with built-in compliance standards. Create, track, and document inspections, cleaning routines, and corrective actions with every task timestamped and stored — no binders necessary.

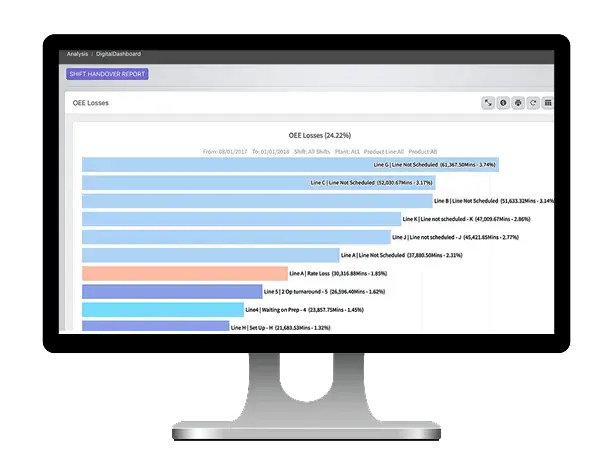

See and fix bottlenecks fast

Spot inefficiencies in real time with live OEE KPIs and bottleneck analysis. See the impact of cleaning stops, maintenance delays, and performance drops down to every line and shift so you always know what's happening.

Make detailed reports in seconds

Get full traceability and audit-ready reporting instantly, with complete histories of maintenance, calibration, quality checks, and safety actions so you can stay ahead of inspections with zero extra admin.

Better together — CMMS + OEE

Use each system alone or connect them for maintenance reliability and production performance that power each other. Trigger work orders in the CMMS automatically when the OEE identifies a problem and see a completed repair reflected in the OEE dashboards. Start with one system and connect when you're ready for full visibility.

The old way

- Paper-based safety and maintenance logs

- Audit panic and missing data

- Downtime and waste hidden in reports

- Reactive, isolated teams

The new way

- All checks and tasks documented digitally

- Audit-ready at any time

- Real-time OEE insights for fast action

- Maintenance and production aligned

Choose CMMS for control.

Choose OEE for visibility.

Combine both for excellence.

frequently asked questions

- Why do companies in the food and beverage industry choose Maintmaster?

- Maintmaster helps companies in the food and beverage industry to be successful by providing tools for BRC & IFS compliance, quality control and documentation, easy management of external audits, and tracking key performance indicators.

- What role does Maintmaster play in quality control and documentation?

-

Maintmaster provides access to critical HACCP documentation, enabling companies to have a live view of their equipment and work orders and to easily track and improve processes if needed.

- How does Maintmaster help with BRC & IFS compliance?

- Maintmaster offers the ability to tailor the system to meet the standardisation demands of BRC and IFS, giving companies full control over production and enabling them to be successful.

- How does Maintmaster help with external audits?

- Maintmaster provides the ability to create audit reports within the software that is up to standard, giving companies an easy way to show the history of their equipment and work orders during external audits.

- What are Key Performance Indicators and how does Maintmaster help with them?

- Key Performance Indicators (KPIs) are critical metrics for success in the food and beverage industry. Maintmaster helps companies track KPIs by tailoring the system to their needs and offering over 20+ years of maintenance expertise.