Downtime reduction

Unite maintenance and production for peak performance

Align maintenance and production to boost uptime and efficiency. Maintmaster’s intuitive CMMS fits your workflow to support lean, continuous improvement.

Why teams use Maintmaster CMMS

Connect maintenance and production in real time

Enable seamless communication between teams to eliminate delays and confusion.

Simplify fault reporting and response

Capture issues instantly and route them automatically to the right technician.

Boost uptime and

collaboration

Align daily priorities across departments for smarter, faster decisions.

Turn disconnection into collaboration

Before

Inefficiency starts small. But quickly adds up.

In fast-paced manufacturing, small inefficiencies can snowball. Disconnected tools, unclear priorities, and inconsistent communication make collaboration between maintenance and production difficult.

Without shared visibility, teams react instead of plan — causing delays, extra costs, and avoidable downtime.

Action

See clearly. Act swiftly.

Maintmaster brings maintenance, production, and management together in one platform. Faults are reported instantly, workflows are automated, and incidents are tracked centrally. Built-in analytics — including basic OEE — give every team the insights they need to make faster, data-driven decisions.

Result

A unified, data-driven workflow

With shared dashboards, clear communication, and traceable data, teams work as one. Production runs smoothly, maintenance is proactive, and decisions are based on facts — not assumptions.

Powerful features that keep

production and maintenance

aligned

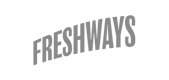

One dashboard. One truth.

Get a single view of equipment status, active jobs, and performance metrics. Real-time monitoring and alerts ensure you act before problems escalate.

Capture faults in seconds

Operators scan a QR code to log faults or maintenance requests directly at the machine. Every issue is documented, tracked, and resolved faster.

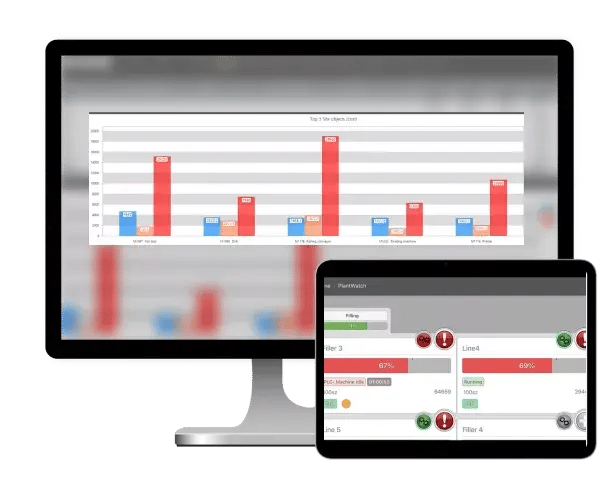

Understand and improve performance

Visualise availability, performance, and quality metrics instantly. Identify bottlenecks and drive improvement — with advanced OEE analysis available through Maintmaster OEE.

Proven results — Where maintenance meets production

Visibility of compliance metrics

Increaced productivity

Fewer administration hours

Before and after

Maintmaster CMMS

The old way

Disconnected and reactive

- Paper-based fault reporting

- Miscommunication between teams

- Unclear priorities and responsibilities

- Reactive maintenance culture

The new way

Connected and aligned

- Shared dashboards and workflows

- Instant communication and updates

- Data-driven planning and analysis

- Continuous improvement mindset

Align maintenance and production with Maintmaster CMMS

One platform for uptime and efficiency

Maintmaster CMMS brings maintenance and production together in perfect sync. With an intuitive CMMS that fits naturally into your existing workflow, you can boost uptime, minimise downtime, and drive continuous improvement across your operations.

See other CMMS use cases

Maintenance Alerts & Analysis

Identify issues early, prevent unplanned downtime, and move from reactive to proactive maintenance.

Audits & Compliance

Digitise maintenance, ensure compliance, and stay audit-ready without slowing production.

Operator Maintenance

structure, scale, and optimise operator maintenance to boost efficiency and maximise plant availability.

IoT Sensors

Monitor equipment conditions in real time with pre-configured gateways and sensors that integrate seamlessly with your CMMS. Simple to set up and ready to use.

CMMS & AI

Turn maintenance data into clear, actionable insights. Helping teams spot patterns, solve root causes, and improve reliability.

Learn moreFrequently asked questions

- How does Maintmaster improve communication between maintenance and production?

-

Centralised data and shared dashboards ensure transparency and smoother collaboration.

- Can operators use Maintmaster effectively?

- Yes. The mobile app allows quick reporting, TPM activities, and real-time updates.

- Does Maintmaster track production efficiency (OEE)?

- Yes. Maintmaster CMMS includes basic OEE, while Maintmaster OEE provides advanced analytics.

- How adaptable is Maintmaster to our processes?

- Highly adaptable — dashboards, workflows, and KPIs can be tailored easily.

- Does Maintmaster support compliance and audits?

-

Absolutely. Built-in documentation and reports simplify compliance.