Take your preventive maintenance further

Maintmaster IoT connects ready-to-use sensors and gateways to your CMMS—easy setup, no IT needed.

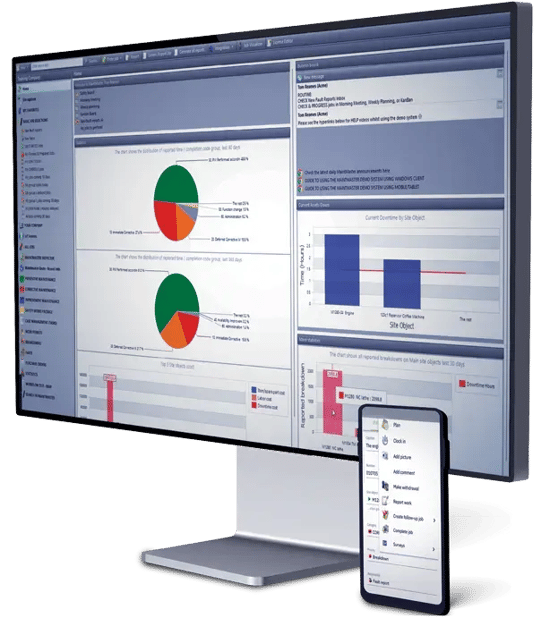

Connected data for smarter maintenance

Seamless CMMS Integration - No data silos, no guesswork

MaintMaster IoT ensures that all sensor data flows directly into your CMMS - no manual tracking and no disconnected systems.

Every reading, every alert and every work order is connected and actionable.

Real-time condition monitoring

Track asset conditions with LoRaWAN sensors tailored to meet your specific maintenance needs.

Maintmaster IoT continuously tracks your asset conditions and sensors can be configured for tailored intervals and thresholds to meet your specific needs.

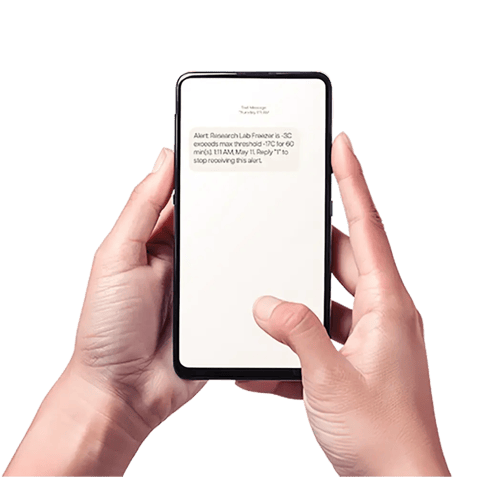

Set the limits that matter to you and get instant alerts when sensor readings deviate from those limits so that your team can act fast and stay in control.

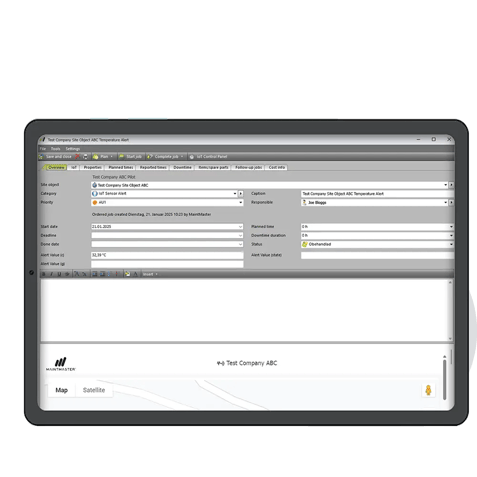

From sensor alerts to work orders instantly

Automate work orders the moment an issue is detected.

When the sensor detects a threshold breach, MaintMaster IoT can instantly generate a work order within MaintMaster CMMS, reducing both response time and manual intervention.

Get notified via SMS or email and customise alerts and workflows to match your maintenance needs.

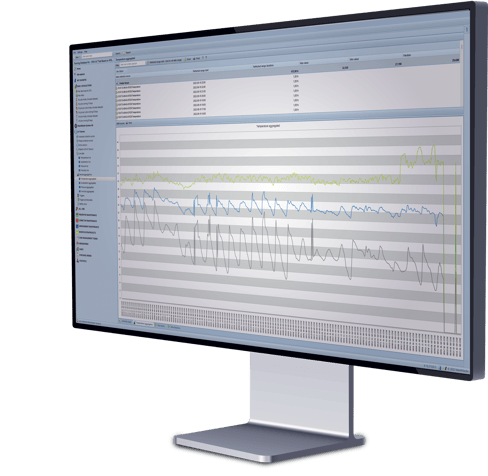

Stay ahead with preventive maintenance insights

Harness real-time and historical data to detect trends, reduce downtime and extend asset life.

MaintMaster IoT turns real-time and historical data into actionable insights, helping you optimise your maintenance.

Anticipate maintenance needs with data-driven insights by analysing trends and historical information. You can anticipate wear, schedule maintenance at the right time and prevent unplanned downtime - keeping operations efficient and uninterrupted.

Advanced monitoring and predictive insights made easy

Multiple sensor types for versatile use cases

- Temperature – Ensure compliance for food, pharma and climate-sensitive goods.

- Energy Usage – Optimise power consumption, identify inefficiencies and prevent cost spikes.

- Humidity & Vibration – Monitor humidity and vibration to ensure optimal operating conditions and detect early signs of machine failures.

- Pressure Monitoring – Ensure operational efficiency and safety by tracking pressure fluctuations, leaks or blockages.

Simple data visualisation and analytics

- Dashboard views of sensor data, including trends and historical charts.

- Alerts and sensor readings displayed in both list and graphical formats.

- Web-based platform with real-time monitoring.

Reliable connectivity and long-range communication

- Uses LoRa (Long-Range) technology offering better coverage than wifi in industrial environments.

- Supports SIM-based gateways for independent, plug-and-play connectivity without IT setup.

Secure and future-proof system

- Cloud-based platform ensures data handling.

- APIs allow further automation and easy scaling as business grows.

IoT sensor use cases

Discover all the ways you can use MaintMaster’s IoT Sensors to improve your condition-based maintenance.

Use case: Food temperature control

Perfect food management with steady temperatures

Avoid spoilt food or expensive machine breakdown with accurate, real-time temperature monitoring of all your critical equipment. Get automatic notifications and work orders assigned to the right expert when a deviation is detected.

Hot or cold? Perfect.

Maintaining temperatures is vital for many manufacturers handling sensitive foods that need unbroken cold chains from production to distribution. Take the temperature with IoT sensors before deviations indicate incoming breakdowns.

And monitor temperature and more data even in extreme temperatures. Get real-time insights and see historical trends to make temperature control easier – with automatic work order creation in your Maintenance Software.

Ready to take the temperature?

Maintain safe food storage temperatures

Set your desired temperature range and receive instant alerts if temperatures deviate, helping you to prevent potential food spoilage and contamination before it becomes a problem.

Food temperature monitoring from everywhere

Say goodbye to manual inspections and have real-time temperature information from anywhere, at any time, ensuring the freshness and safety of your food.

Let sensors create work orders

Say goodbye to manual work order creation. When a sensor detects a temperature deviation, it automatically creates and assigns work orders to your chosen person or team.

See trending temperatures

Improve your preventive maintenance monitoring with historical equipment data and trending insights on temperatures, vibrations, relative humidity and air pressure.

Use case: Hard-to-reach places

Monitor your dangerous and unreachable assets risk-free

Monitor equipment in hard-to-reach or hazardous places without losing valuable production time or risking your or your team’s safety.

Discover sensors that love a challenge

Most premises have equipment in isolated or even hazardous places. With these plug-and-play sensors, simply power on the pre-configured Gateway, activate the sensor and mount it to the asset - seamlessly connecting it to the IoT platform for real-time monitoring.

Forget dismantling machines or looking for ladders. Get real-time insights and see historical trends to make proactive maintenance easier – with automatic work order creation when the sensors find deviations. Inspect with a click in MaintMaster CMMS.

Ready to cut your number of risky inspections?

Improve your safety

MaintMasters IoT sensors can be placed in hazardous or hard-to-reach locations, enabling remote monitoring and control to reduce risk to human workers.

Increase your efficiency

Our IoT sensors can provide real-time data on conditions in hard-to-reach places, enabling more informed decision-making and optimised operations.

Be better at maintenance

Our IoT sensors can provide early warning signs of potential problems, enabling

preventive maintenance to be carried out before failure occurs, reducing downtime and maintenance costs.

Enhance your data collection

MaintMasters IoT sensors can collect data in remote or challenging environments, providing valuable information that would otherwise be difficult or impossible to obtain, enabling data-driven improvements and decision making.

Use case: Scaling monitoring

Power on and activate the sensor to scale your maintenance

Scale your maintenance with plug-and-play IoT sensors. Measure all assets you depend on with a direct connection to your CMMS for an unbeatable overview.

Monitor all equipment that counts

Typically, the Internet of Things and sensors are luxuries saved for your most critical machines. Not anymore. With affordable and powerful plug-and-play IoT sensors, monitor all your key facility essentials like ventilation, energy consumption and equipment health.

Monitor all equipment limitlessly and get automatic work orders created and assigned when sensors detect a deviation. Your most important machine data feeds into your Maintenance Software around the clock – giving you insights to improve efficiency and productivity.

Ready to take maintenance to the next level?

Centralise your monitoring

MaintMasters IoT sensors enable the centralisation of monitoring data, making it easier to view, analyse and manage multiple assets and systems from a single location.

Automate your monitoring

With MaintMasters IoT sensors, you can automate the monitoring process, reducing the need for manual checks and freeing up time for other tasks.

Increase data visibility

MaintMasters IoT sensors provide real-time visibility into the performance of assets and systems, allowing you to identify and resolve issues before they become major problems.

A scalable solution

MaintMasters IoT sensors are scalable, allowing you to easily add or remove sensors as your monitoring needs change, ensuring you always have the level of visibility you need to effectively manage your assets.

Technical Whitepaper

Download our technical whitepaper for the IoT Sensors.

Leaflet IoT

Download our leaflet for the IoT Sensors.

Unleash the power of maintenance with Maintmaster!

Say goodbye to compliance headaches and hello to effortless maintenance management with Maintmaster. Designed with European Maintenance Standard (EN 13306:2017) in mind, it offers a user-friendly interface that simplifies maintenance planning and boosts productivity. Get real-time data and insights to keep your business running smoothly and easily.

Streamline work orders, schedule preventive maintenance and easily track inventory levels. The built-in mobile app gives technicians the flexibility to access work orders and critical information on the go, facilitating seamless communication with supervisors. Upgrade your maintenance game with Maintmaster today!

See other CMMS use cases

Other use cases

Production & Maintenance Allignment

Boost uptime and efficiency with seamless alignment between maintenance and production.

Maintenance Alerts & Analysis

Identify issues early, prevent unplanned downtime, and move from reactive to proactive maintenance.

Audits & Compliance

Digitise maintenance, ensure compliance, and stay audit-ready without slowing production.

Operator Maintenance

structure, scale, and optimise operator maintenance to boost efficiency and maximise plant availability.

CMMS & AI

Turn maintenance data into clear, actionable insights. Helping teams spot patterns, solve root causes, and improve reliability.

Learn morefrequently asked questions

- What are IoT sensors and why do they matter for maintenance?

- IoT sensors are plug-and-play add-ons for your maintenance software (CMMS). They track asset condition continuously and in real time, so you can spot deviations long before a failure. Result: fewer unplanned stops, higher reliability, and a shift from reactive to proactive (predictive) maintenance.

- Which measurements do IoT sensors capture?

-

Standard metrics include:

-

Temperature

-

Vibration (three-axis acceleration)

-

Relative humidity

-

Air pressure

These enable condition-based maintenance and help uncover energy inefficiencies.

-

- How are sensors set up and integrated with the CMMS?

- Installation is quick: battery-powered, wireless, and truly plug-and-play—even at scale. Data flows straight into the CMMS (e.g., MaintMaster). Configure variables, alerts, and actions in the familiar UI—no coding required. The goal: turn data into clear actions for more reliable production.

- Where do sensors deliver the most value?

-

Use them when:

-

Inspections would stop production

-

Assets are hard to reach or require disassembly

-

Deviations aren’t visible to human senses (e.g., vibration, temperature)

-

Inspections pose health or safety risks

Example: temperature monitoring for sensitive foods to prevent spoilage and downtime.

-

- What happens if a sensor detects a critical deviation?

- When a threshold is exceeded, the system sends an instant alert (email or SMS) and automatically creates a work order in the CMMS. It’s routed to the right technician/skill, speeding response and reducing manual effort.