- MaintMaster CMMS

- MaintMaster helps Finance Managers to reduce costs

A CMMS THAT HELPS REDUCE COSTS

Why Finance Managers LOVE maintenance departments using MaintMaster

GET THE STOCK RIGHT

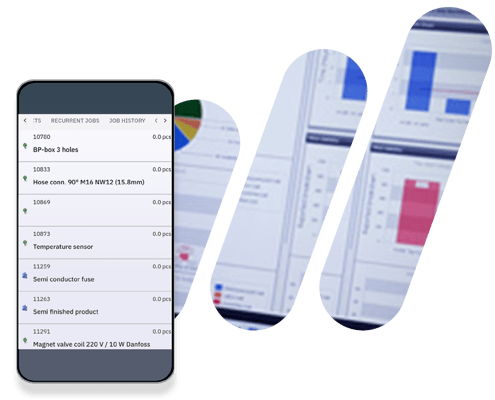

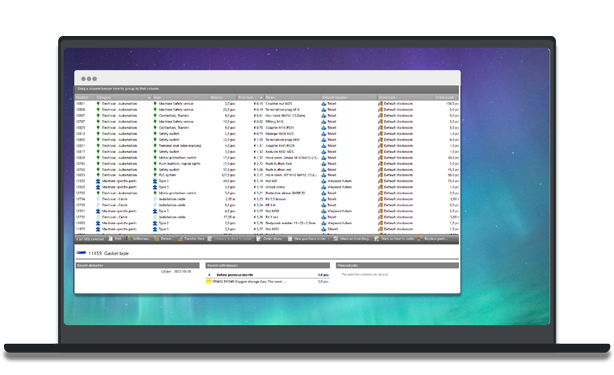

In MaintMaster, all data, from documents to job orders, are stored in one place. Even purchase and stock data are accessible through the platform. The best thing is, that you can easily create reports around that. If you need numbers from the maintenance department for the inventory check? No problem. The team can provide those in a quick and easy way. Your stock will always be up to date.

KEEP TRACK OF COSTS

In MaintMaster it is easy to link maintenance to a cost centre. Because everything can be tracked in our maintenance software, such as downtime, technician hours or materials used. With the right setup, maintenance is no longer a black hole in your business. Finance can always monitor the total cost of maintenance. Really good when it comes to presenting the figures to stakeholders and shareholders.

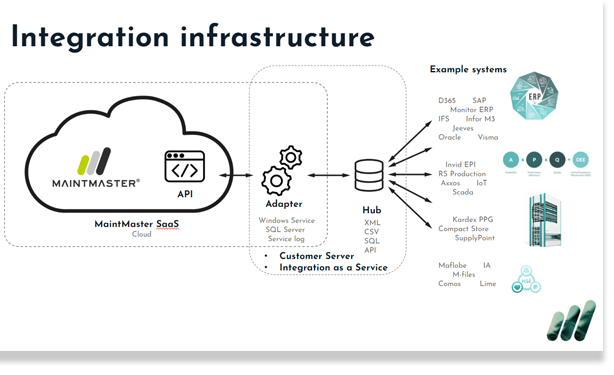

MAINTMASTER IS EASY TO INTEGRATE

Our integration services make it easy to integrate MaintMaster into your existing system environment. We can help you set up the integration programme and provide support and maintenance for the integration process, whether you're using SAP, IFS or other ERP systems or controlling tools. You'll be able to get MaintMaster data directly into your preferred tool.

FOR YOUR INDUSTRY

- Process Industry

-

-

We decided to go for MaintMaster because of their tool flexibility, the customer support they provide and how willing MaintMaster is to take on board our input to further improve the quality of their products. Manuel Medina, Engineering Projects Manager, Gränges Americas Inc Read more about Gränges success

-

Did you know that the first customer that joined MaintMaster, was from the process industry? Therefore, we consider us an expert in the field. With over 20 years of experience, we know how hard and challenging it can be to operate in this industry, that’s why we are here to make it easier for you! Check out the industry

-

- Food & Beverage

-

-

With our previous solution, it obviously would cost us a lot of money to change anything. They wanted us to work to their system. Your system will work to whatever we want. It’s so versatile that we can basically make it do anything. Geoff Kynaston-Stear, H&S Manager, Bedgrow Read more about Bedgrows success

-

The Food and Beverages industry have a high standard when it comes to production, with all the documentation that needs to meet the standards. With pen and paper this is an impossible task, but with MaintMaster you can feel comfortable that you have everything you need to be a successful producer. Check out the industry

-

- Automotive

-

-

We have built up a high level of trust for the maintenance department, and, thanks to the continuous dialog with the production, there’s always a relatively high understanding for preventive maintenance. Erik Arnesson, Project Manager, Automotive Components Floby AB Read more about AC Flobys success

-

Working in a stressful environment is a common thing for people in the automotive industry. But does it really have to be like this? The answer is no, and the solution is MaintMaster. Check out the industry

-

- Energy & Engineering

-

-

There are many people in maintenance that have worked with MaintMaster. And as it turned out, MaintMaster was that good that we didn’t need to try anything else. Anders Carlberg, Production Technician, Svensk Plaståtervinning Read more about Svensk Plaståtervinning success

-

Working in a high demanding environment can be a very stressful task, but when you have a maintenance software that can help you plan your day-to-day work, it becomes a lot easier. No more excel files and running around printing papers. Check out the industry

-

- Manufacturing

-

-

Entering the number of the work order directly on the invoice makes it possible to monitor easily the jobs that have been completed, and to match them against our own records. Stefan Svensson, Maintenance Manager, Anzla Orkla House Care Read more about the success at Anzla Orkla House Care

-

When working within the manufacturing industry you are working with raw materials that need to be transformed into finished products that other industries can use in their production, and in some cases even the consumer itself. That’s why the manufacturing industries needs to have a dynamic maintenance system, just like MaintMaster. Check out the industry

-

-

We decided to go for MaintMaster because of their tool flexibility, the customer support they provide and how willing MaintMaster is to take on board our input to further improve the quality of their products. Manuel Medina, Engineering Projects Manager, Gränges Americas Inc Read more about Gränges success

-

Did you know that the first customer that joined MaintMaster, was from the process industry? Therefore, we consider us an expert in the field. With over 20 years of experience, we know how hard and challenging it can be to operate in this industry, that’s why we are here to make it easier for you! Check out the industry

-

With our previous solution, it obviously would cost us a lot of money to change anything. They wanted us to work to their system. Your system will work to whatever we want. It’s so versatile that we can basically make it do anything. Geoff Kynaston-Stear, H&S Manager, Bedgrow Read more about Bedgrows success

-

The Food and Beverages industry have a high standard when it comes to production, with all the documentation that needs to meet the standards. With pen and paper this is an impossible task, but with MaintMaster you can feel comfortable that you have everything you need to be a successful producer. Check out the industry

-

We have built up a high level of trust for the maintenance department, and, thanks to the continuous dialog with the production, there’s always a relatively high understanding for preventive maintenance. Erik Arnesson, Project Manager, Automotive Components Floby AB Read more about AC Flobys success

-

Working in a stressful environment is a common thing for people in the automotive industry. But does it really have to be like this? The answer is no, and the solution is MaintMaster. Check out the industry

-

There are many people in maintenance that have worked with MaintMaster. And as it turned out, MaintMaster was that good that we didn’t need to try anything else. Anders Carlberg, Production Technician, Svensk Plaståtervinning Read more about Svensk Plaståtervinning success

-

Working in a high demanding environment can be a very stressful task, but when you have a maintenance software that can help you plan your day-to-day work, it becomes a lot easier. No more excel files and running around printing papers. Check out the industry

-

Entering the number of the work order directly on the invoice makes it possible to monitor easily the jobs that have been completed, and to match them against our own records. Stefan Svensson, Maintenance Manager, Anzla Orkla House Care Read more about the success at Anzla Orkla House Care

-

When working within the manufacturing industry you are working with raw materials that need to be transformed into finished products that other industries can use in their production, and in some cases even the consumer itself. That’s why the manufacturing industries needs to have a dynamic maintenance system, just like MaintMaster. Check out the industry

MaintMaster is the ultimate solution for finance managers looking to maximise assets, minimise downtime and control costs. The maintenance system streamlines operations, provides real-time visibility of maintenance activities and enables better budget management.

- 30 Fewer Downtimes

- 25 Reduced Stock Levels

- 60 Maintenance Productivity

- 80 Better Cost Control

WANT TO KNOW MORE ABOUT OUR FEATURES?

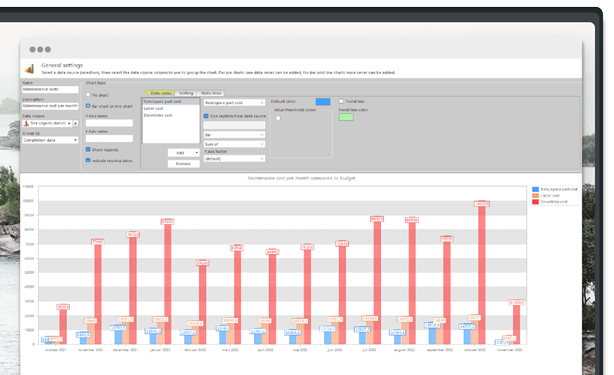

Join us as we delve into the world of data-driven maintenance. By visualising maintenance insights and analysing data, we're able to pinpoint key areas for improvement.

Read more about Analysis and Reporting

Instantly access records, job history and other critical data with a simple scan of a QR code on your mobile device. Keep your technicians in the loop with integrated safety information.

Read more about Mobile Maintenance

MaintMaster IoT Sensors. A plug-and-play addition to your MaintMaster CMMS that will change the game. These sensors detect deviations before they become breakdowns.

Read more about IoT sensorsBetter cost control with Maintmaster - customer stories

How Siva Group leveraged MaintMaster CMMS for organisational growth

BEWITAL's path to efficient operating processes,

Glas Trösch's Efficiency Boost in Maintenance

Finance

frequently asked questions

- How does MaintMaster help reduce costs?

- MaintMaster allows both the maintenance department and production to plan, track, and measure their work and budget, resulting in improved performance and decreased costs.

- Does MaintMaster store all data in one place?

- Yes, MaintMaster stores all data, including documents and job orders, in one place and even purchase and stock data are accessible through the platform.

- Can MaintMaster track maintenance costs?

- Yes, MaintMaster can link maintenance to a cost centre and track various elements, such as downtime and materials used, to monitor overall maintenance costs.

- Is MaintMaster easy to integrate into existing systems?

- Yes, MaintMaster provides integration services and support to easily integrate into existing system landscapes, such as SAP, IFS, or other ERP systems or controlling tools.

- Can MaintMaster data be accessed directly in other tools?

- Yes, MaintMaster data can be accessed directly in the user's preferred tool through the integration process.