MaintMaster

+ OEEsystems

MaintMaster and OEEsystems will empower manufacturers to get to the next level of operational excellence. Maintenance and production departments will benefit from streamlined workflows and seamless real-time collaboration.

MaintMaster has acquired OEEsystems, a state-of-the-art OEE software. MaintMaster's CMMS and OEEsystems' software will smoothly work together.

Learn more below 👇

Customer focus at our core

Founded 30 years ago on the simple idea of creating a better way for how maintenance teams work and that maintenance can have a positive effect on production. Our groundbreaking approach is empowering everyone to do their work as works best for them.

We want to transform the way maintenance teams work. Now we are able to transform how to optimise your production and maintenance with the right information exactly when you need it.

Key customer benefits

- Reach new heights of operational efficiency with plug-and-play synergies between MaintMaster and PerformOEE.

- Bridge maintenance and production to improve quality with shared real-time performance insights data stream.

- Maximise uptime while reducing costs with automated maintenance resource allocation based on best needs.

- Empower operators to improve maintenance with timely and accurate information.

- Drive continuous improvements with maintenance and production industry leaders, accelerating your every step to scale performance excellence.

"By broadening our offering, we are not only adding a state-of-the-art product but also a wealth of knowledge that our customers will benefit from. Now, we will have two products that can either be used stand-alone or have them seamlessly connected and benefit from the data from both operations as well as maintenance. We see this combination as a perfect match."

— Isac Wiksten, CEO, MaintMaster.

OEE Software is a tool for Business Performance Management, offering unparalleled effectiveness in evaluating the utilisation of manufacturing operations. OEE (Overall Equipment Effectiveness) is your journey towards continuous improvement, adaptable to both singular and multiple production lines, spanning across individual plants or within a group-wide framework. Its versatility extends across all manufacturing process types, be it discrete, continuous, or bulk.

To put it succinctly, "The paramount OEE Software boldly delineates the chasm between a manufacturing unit's actual performance and its boundless potential."

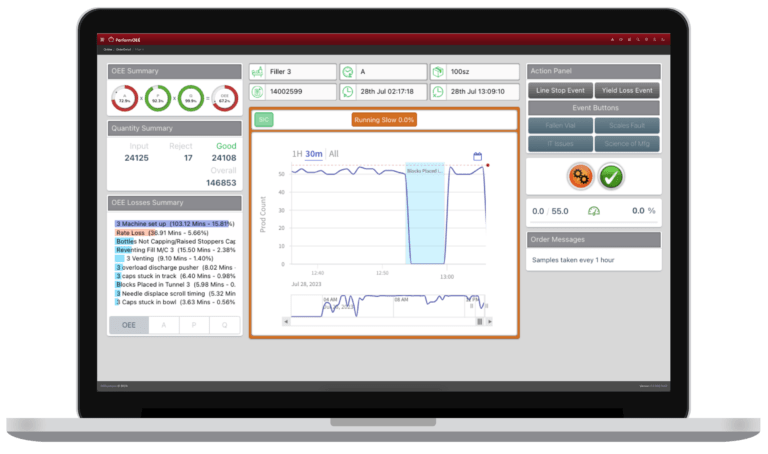

Real-Time Production Monitoring and Control

PerformOEE™ gives you real-time Production Monitoring & Control by highlighting production performance issues and enabling your team to respond in the right way. As your team becomes more proactive, issues are managed more effectively or eliminated entirely. Features include slow running detection, APQ and OEE performance, OEE Loss and live time-analysis display, product current state.

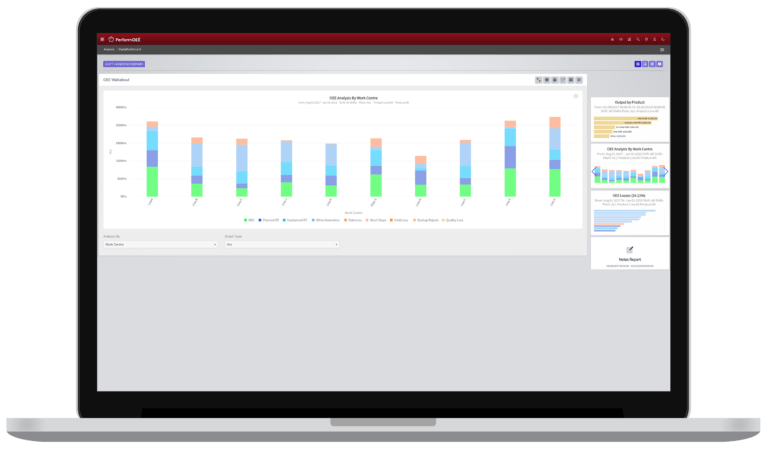

Continuous Improvement Analytics Dashboard

PerformOEE™ empowers continuous improvement with intuitive 'click-as-you-think' Big Data Analysis. Its 'Follow The Data' approach inpoints opportunities for optimisation, while the CPC Module helps your improvement teams solidify and sustain those gains.

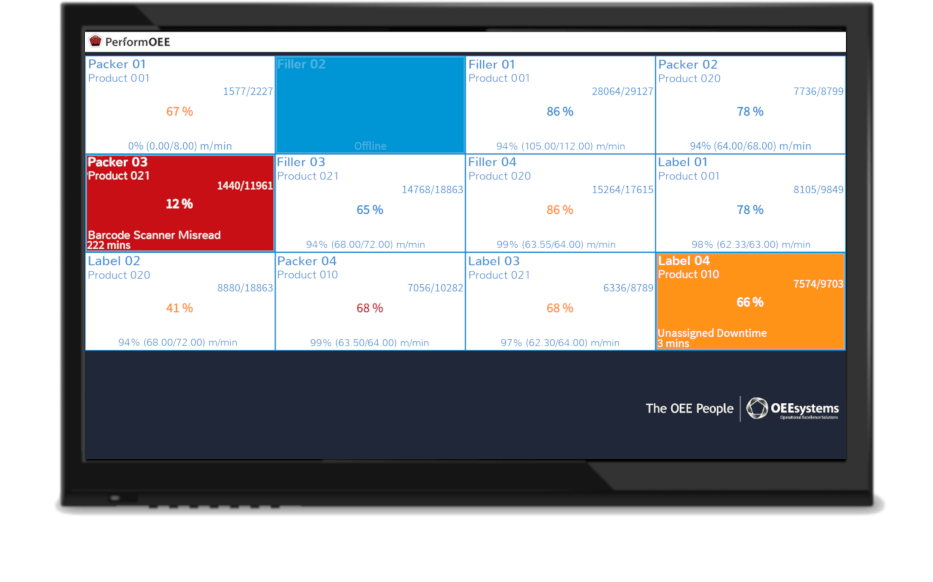

Visual Smart Factory Departmental KPI Displays

PerformOEE™ Spotlight delivers Visual Factory for your Manufacturing Operations enabling the deployment of fit-for-purpose displays in your key Manufacturing and Support Departments. This enables your team to become more proactive and respond to issues in the right way. Example screens such as current process status, project target status, breaches, and CPC trending status.

MaintMaster + OEEsystems

Accelerate Manufacturing Excellence

MaintMaster + OEEsystems helps global manufacturers reach new heights of operational efficiency without complex integrations. The connected solution helps you bridge maintenance and production and improve quality with a shared real-time performance insights data stream.

Maximise uptime while reducing costs with automated maintenance resource allocation based on best needs and empower operators to improve maintenance with timely and accurate information.

Drive continuous improvement with maintenance and production industry leaders, accelerating your every step to scale performance excellence.

Contact us to learn more about OEE software and the combination with MaintMaster

.jpg?width=2000&height=561&name=PerformOEE%20logo%20(hi%20res).jpg)