Increase in total output

Standardise changeovers. Maximise capacity.

Unlock capacity without adding headcount or equipment by turning every changeover into a repeatable success.

Why teams use Maintmaster OEE

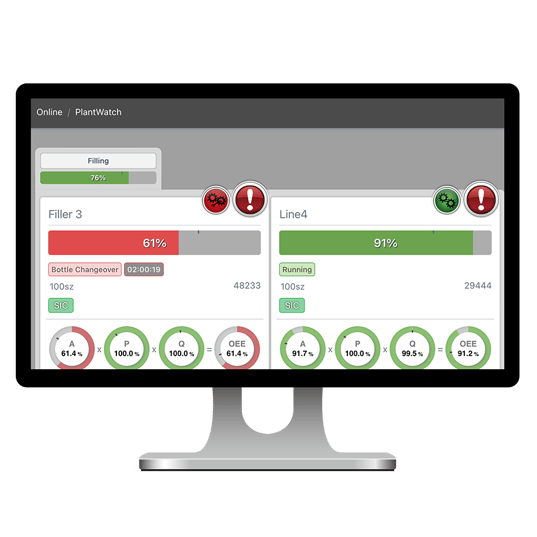

Stop guessing. See every changeover live

Track exact start, end and ramp-up time in real time. Step in early — not after it’s too late.

Capture the true cause

of delays

Operators log root causes quickly and accurately using pre-defined downtime reasons.

Make your best performance the standard

Turn your fastest, cleanest changeover into the new baseline for every team.

From daily tasks to daily improvement

Before

Changeovers that swing from 18 to 42 minutes

Changeovers range from 18 to 42 minutes, depending on the shift. Tools go missing, cleaning overruns, and steps get skipped. Standards exist but aren’t followed.

The result? Missed output targets, poor OEE, and the same issues repeating shift after shift.

Action

Make changeovers visible, measurable and repeatable

A live timer shows exactly how long each changeover takes. Operators can log delays in real time, tagging root causes like tooling, cleaning or setup.

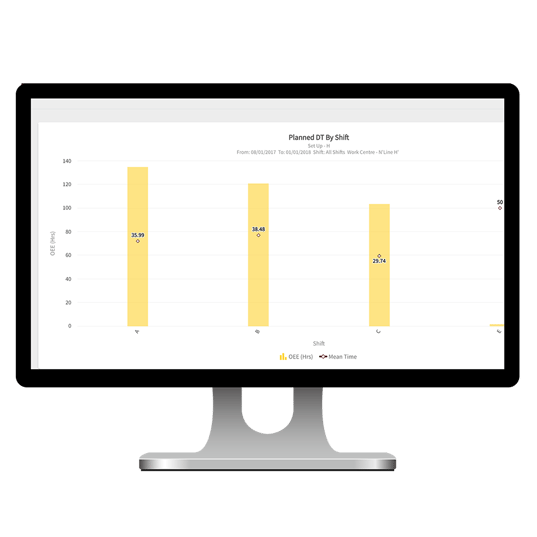

Dashboards, timelines and Pareto charts reveal where time is lost — so issues are fixed fast and stay fixed.

Result

Consistent changeovers that keep production on-track

Once your best-performing changeover is identified, Maintmaster makes it easy to share that insight and track how future changeovers compare.

Teams know what a ‘good’ changeover looks like and can spot when performance slips — so improvements stick and capacity gains are protected.

Built to make changeovers

faster, smarter and

more reliable

Track changeovers in real-time

Monitor exactly how long each changeover takes — down to the second.

No more waiting for shift-end reports. See progress live, intervene early, and keep production moving.

Capture the real causes of delay

Operators log downtime causes as they happen, from tooling to setup or cleaning.

Split delays to capture multiple reasons, giving you clearer data to fix what matters.

Turn performance into a standard

Use dashboards, timelines and Pareto charts to analyse every changeover.

Define what “good” looks like — and set it as the new benchmark across lines or shifts.

Real results - Teams using Maintmaster OEE to control changeovers report:

OEE lift across monitored lines

Reduction in changeover variance

"Maintmaster OEE confirmed massive variation in batch changeovers. When we standardised them, OEE lifted straight away."

- Rob George, Asset Care Manager, CooperVision UK

"We’ve seen a 25% reduction in allergen changeover time — just by having the data from the OEE system show us where time was being lost."

- Eric Steer, VP of Operations, Chairmans Foods

Before and after

Maintmaster OEE

The old way

Unpredictable and unstructured

- Wide variation between shifts

- No real-time visibility

- Vague or missing root cause insight

- Poor handovers

The new way

Standardised and controlled

- Real-time monitoring

- Root cause logged per event

- Alerts when performance slips

- Consistent, fast changeovers

Take control of your production with Maintmaster OEE

Real-time insights into every machine, every shift

Optimise your changeovers with MaintMaster OEE — the performance platform built for real-world production. Reduce variation, capture root causes and unlock hidden capacity with live data that drives smarter decisions. Start where it matters most, then scale at your pace, when your team is ready.

See other OEE use cases

Preventing Unplanned Downtime

Spot downtime as it happens, uncover root causes fast, and prevent disruptions before they hit your targets.

Performance Benchmarking

Create one version of the truth across all sites, reveal hidden losses, and drive measurable improvement.

Production Monitoring

Spot downtime as it happens, uncover root causes fast, and prevent disruptions before they hit your targets.

Supporting CI Projects & Teams

One source of truth for every team, turning data debates into measurable results on every shift.

Teams & Visual Performance Data

Clear, real-time insights that keep every shift aligned and prevent small losses from becoming big problems.

OEE & AI

Turn production data into clear, actionable insights. Helping teams spot losses, fix root causes, and boost performance every shift.

Learn moreFrequently asked questions

- How exactly does the Maintmaster OEE reduce changeover time?

-

MaintMaster OEE tracks each changeover event in real time, compares it to your best historical performance, and flags where delays happen, whether it’s tooling, cleaning, waiting on approvals, or unclear procedures. That visibility lets you identify what’s slowing teams down and fix it fast.

- Can we standardise changeovers across shifts or lines?

-

Yes. The software helps you set achievable, line-specific standard times based on real data. It tracks adherence shift by shift, making it easy to spot variation and drive consistency across teams so everyone’s aiming for the same target.

- How do we know what’s causing variation?

-

Root-cause analytics show exactly where time is lost and why from machine readiness to manual tasks. You can filter by line, product, shift, or team to uncover recurring issues. No guesswork, just facts you can act on.

- Will operators need to enter extra data during changeovers?

- Most of the data is captured automatically from your equipment, but it can help when the operators can add additional context or detail. Where operator input is needed (like splitting a downtime reason), it’s quick and simple, designed not to slow anyone down.

- We’ve already worked on reducing changeover time - what’s different here?

-

You might have done time studies, made physical improvements, or even implemented SMED (Single-Minute Exchange of Dies). But the hardest part isn’t reducing the time - it’s keeping it down. MaintMaster OEE helps your team stick to the process that works. So when performance slips, you see it early - and can act before it becomes your new baseline.