OEE improvement <6months

Stop unplanned downtime before it stops you

Downtime disrupts schedules and hurts output. Maintmaster OEE gives you live insight to spot issues early and keep production moving.

Why teams use Maintmaster OEE

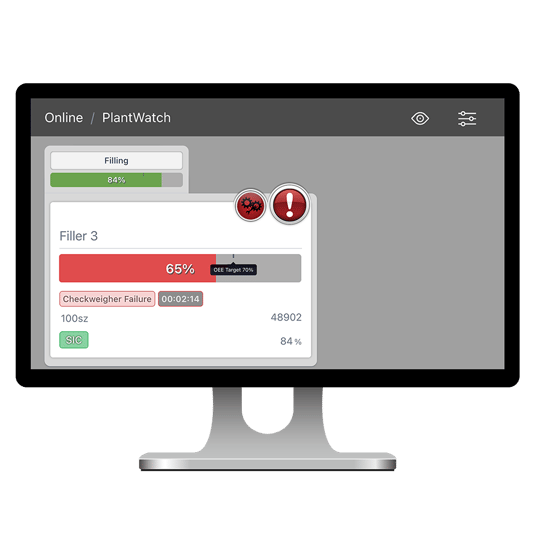

See problems as they happen

See live status across every area and workcentre with visual alerts for unplanned stops, slow cycles or alarms.

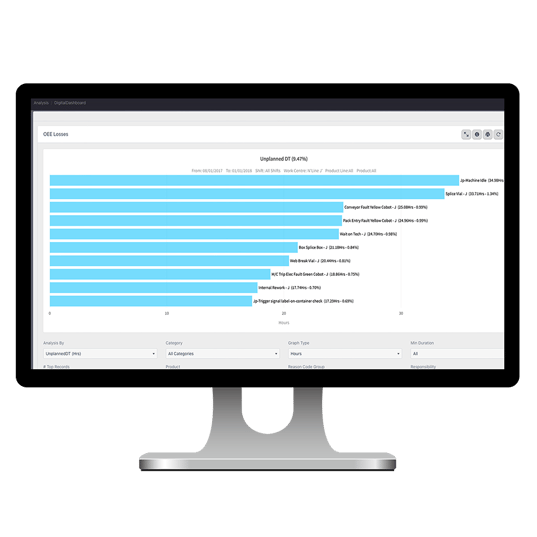

Find and fix root causes fast

Reveal underperforming lines, inefficient changeovers, or recurring losses in minutes.

Keep improvements locked in

Real-time monitoring, alerts, and targets help sustain performance and prevent recurring issues.

From firefighting to foresight

Before

Small problems that keep coming back

Most downtime doesn’t start with a major failure — it starts small: a tripping sensor, an alarm ignored, a five-minute tweak that becomes routine.

Without real-time visibility, these “minor” stops repeat shift after shift, turning into hours of lost production, missed targets, and frustrated teams.

Action

See, react, prevent

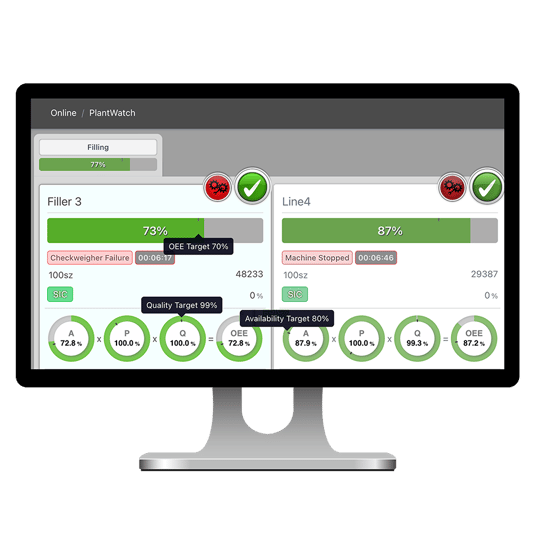

Maintmaster OEE puts live data in front of everyone — operators, engineers, and managers.

Colour-coded dashboards show exactly where downtime happens and why. Built-in Pareto charts highlight top losses, while timelines reveal patterns and repeated events.

Teams no longer wait for end-of-shift reports — they act instantly to prevent problems before they snowball.

Result

Less downtime, more control

Real-time visibility transforms how teams work.

Root causes are identified and fixed faster, operators stay proactive, and performance stabilises across shifts.

Downtime doesn’t take you by surprise — it’s seen, understood, and stopped before it spreads.

Turn visibility into action —

live, clear, and

connected

Spot downtime instantly

See each workcentre’s status in real time: running, slow, stopped, or down for an alarm.

Colour-coded visuals and live KPIs give early warnings before issues grow.

Focus on what matters most

Identify your biggest performance losses instantly.

From slow cycles to quality losses, click-as-you-think charts show where to focus improvement efforts.

Get to the root cause. Fast

Capture alarms and signals automatically.

Operators can split downtime events, add notes, or assign causes with one click — ensuring no event goes unexplained.

Lock in standards and targets

Set live OEE targets for availability, performance, and quality.

Visual cues and alerts trigger when values drop, helping supervisors act mid-shift — not after the fact.

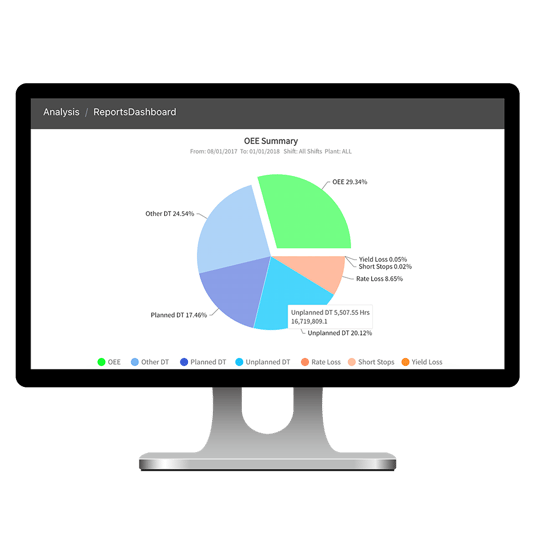

Turn data into continuous improvement

Create dashboards that track the KPIs you care about most.

Run instant reports, share them via email, or export results to keep teams aligned.

Proven results — Data-driven gains in OEE and uptime

Reduction in unplanned downtime

Reduced changeover variance

Reduction in idling and short stops

"Quality is a key element of our process and Maintmaster OEE gives us strong insights as well as early warnings when these types of issues arise."

- CooperVision UK

"Maintmaster OEE is now fully integrated into our daily operations… helping us deliver projects and train our teams on operational problem solving.”

- Müller Milk & Ingredients

Before and after

Maintmaster OEE

The old way

Always one step behind

- Hidden micro-stops and repeat issues

- End-of-shift reporting delays

- Inconsistent fault logging

- Reactive maintenance and firefighting

The new way

Always one step ahead

- Live dashboards and early alerts

- Standardised root-cause tracking

- Fast decisions based on live data

- Stable performance, shift after shift

Take control of your production with Maintmaster OEE

Take control of downtime before it controls your shift

Maintmaster OEE gives you real-time visibility into what's really happening on the shop floor — so you can catch downtime early, fix the root cause fast, and keep production on track. Built by manufacturers, it helps you run more reliably, react faster and sustain performance shift after shift.

See other OEE use cases

Performance Benchmarking

Create one version of the truth across all sites, reveal hidden losses, and drive measurable improvement.

Production Monitoring

Spot downtime as it happens, uncover root causes fast, and prevent disruptions before they hit your targets.

Supporting CI Projects & Teams

One source of truth for every team, turning data debates into measurable results on every shift.

Improving Changeover Efficiency

Make every changeover repeatable, efficient, and a driver of continuous improvement.

Teams & Visual Performance Data

Clear, real-time insights that keep every shift aligned and prevent small losses from becoming big problems.

OEE & AI

Turn production data into clear, actionable insights. Helping teams spot losses, fix root causes, and boost performance every shift.

Learn moreFrequently asked questions

- How does Maintmaster OEE help identify root causes of downtime?

-

It captures events in real time with structured codes, enabling faster and more consistent analysis across shifts and sites.

- Can we automate downtime data capture?

- Yes. Maintmaster OEE connects to your machines using protocols like MQTT or OPC to automatically collect alarms and counters.

- Can we track recurring stoppages across lines and shifts?

- Absolutely. Reports and dashboards reveal patterns across shifts, products, or lines, helping you prioritise corrective actions.

- Will operators use it?

- Yes. Maintmaster OEE is browser-based, mobile-friendly, and built for daily use at the line. Operators engage quickly once they see how it helps prevent recurring problems.

- Do we need a formal CI programme to benefit from benchmarking?

-

Not at all. Benchmarking provides actionable facts for any team, helping prioritise improvements even without a structured CI initiative.