Downtime reduction

Empower your operators. Reduce downtime.

Empower your operators to boost efficiency, control, and plant availability. Maintmaster CMMS turns operator maintenance into a scalable performance driver.

Why teams use Maintmaster CMMS

Actively involve your

operators

Turn operator maintenance into a structured, digital routine that drives performance.

Standardise and scale maintenance

Replace paper-based processes with clear digital work instructions and checklists.

Report and act

in seconds

Catch problems early and keep production moving with fast, simple reporting from the shop floor.

Make operator maintenance work for you

Before

Manual operator maintenance creates bottlenecks

Operator maintenance often lacks structure and clarity. Paper-based processes are time-consuming, prone to error, and difficult to scale.

Responsibility is unclear. Tasks are missed. Information doesn’t reach the right people — or gets lost entirely.

Meanwhile, maintenance departments are overwhelmed with routine jobs that could be handled directly on the shopfloor.

Action

Structure operator maintenance for better performance

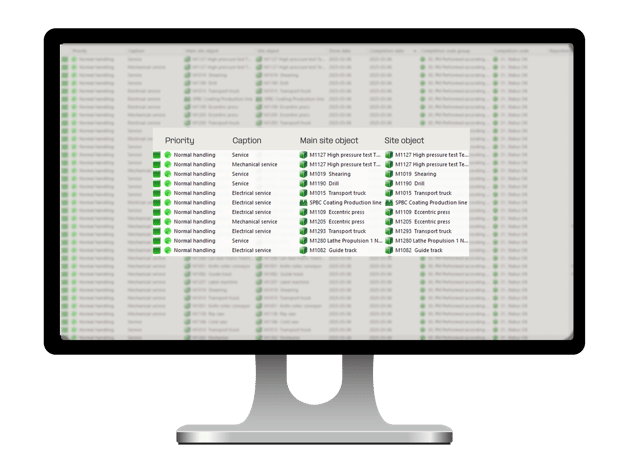

Maintmaster CMMS digitises and streamlines every step of operator maintenance. You can create work instructions, schedule recurring tasks, and assign inspections directly to operators.

Every action is traceable — with digital logs, time stamps, and user documentation.

Result

From routine to performance driver

Operator maintenance becomes part of daily work — structured, transparent, and measurable.

Teams act faster, share responsibility, and eliminate information gaps between production and maintenance.

Maintenance departments gain time for strategic improvements, while frontline teams take ownership of reliability and performance.

Everything you need

to structure

operator maintenance

Keep every task clear and consistent

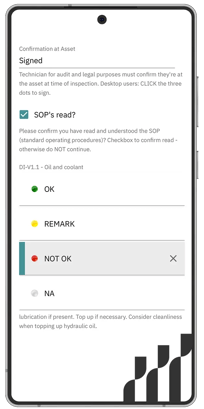

Create structured, role-specific maintenance routines that guide operators step by step. Ensure consistency, safety, and compliance — no more missed checks or unclear responsibilities.

Report and react in real time

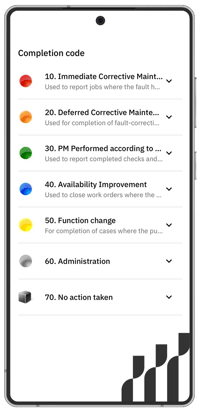

Operators can easily report faults or deviations using the MaintMaster app on any smartphone or tablet. Information reaches the right people immediately — reducing downtime and unplanned stops.

Know exactly what happened and when

Every action is logged with digital time and user stamps.

Gain complete visibility, meet audit requirements, and use data to drive continuous improvement.

Proven results — Empowering operators for efficiency

Visibility of compliance metrics

Increaced productivity

Fewer administration hours

"Communication and cooperation between production and maintenance have become more harmonious, and this has revealed further potential that we would like to continue working on."

- Johannes Schwartz, Plant Manager, Risse + Wilke

Before and after

Maintmaster CMMS

The old way

Manual, unclear, inefficient

- Paper-based checklists

- Missed tasks and unclear responsibility

- Delayed fault reporting

- Overloaded maintenance teams

The new way

Digital, structured, aligned

- Clear digital task assignments

- Real-time fault reporting

- Traceable activity logs

- Empowered, accountable operators

Empower your operators with Maintmaster CMMS

Turn daily routines into performance gains

With MaintMaster CMMS, operator maintenance becomes more than just a checklist. By engaging operators directly in maintenance tasks, you create ownership, transparency, and efficiency. Structure and scale your maintenance activities, reduce unplanned downtime, and maximise plant performance — all in one easy-to-use system.

See other CMMS use cases

Production & Maintenance Allignment

Boost uptime and efficiency with seamless alignment between maintenance and production.

Maintenance Alerts & Analysis

Identify issues early, prevent unplanned downtime, and move from reactive to proactive maintenance.

Audits & Compliance

Digitise maintenance, ensure compliance, and stay audit-ready without slowing production.

IoT Sensors

Monitor equipment conditions in real time with pre-configured gateways and sensors that integrate seamlessly with your CMMS. Simple to set up and ready to use.

CMMS & AI

Turn maintenance data into clear, actionable insights. Helping teams spot patterns, solve root causes, and improve reliability.

Learn moreFrequently asked questions

- How does Maintmaster support operator maintenance?

-

Operators receive tasks, checklists, and instructions via the MaintMaster app — and can document all actions digitally.

- Can operators report faults from the shopfloor?

- Yes. Operators can report issues using a mobile device — including photos and voice messages — directly from the line.

- Is it easy to see who performed a task and when?

- All tasks are automatically tracked and logged with time stamps and user data — ensuring full traceability.

- Can we assign operator tasks by machine or role?

- Yes. Tasks can be assigned based on equipment, role, skill level, or location — providing full flexibility.

- Do I need special hardware?

-

No. Maintmaster runs on standard smartphones and tablets.