Spot downtime as it happens, uncover root causes fast, and prevent disruptions before they hit your targets.

From messy notes to clear insights with AI

Maintmaster MI turns messy text notes into reliable data for everyone. It captures frontline knowledge and transforms it into insights for technicians, managers and leaders. Combined with CMMS and OEE, it shows losses, causes and actions in one place.

Turn overlooked notes into data you can use

Operator logs, shift comments and work orders contain valuable detail. Maintmaster MI makes sense of them, revealing recurring problems and past fixes so your improvements can add up day after day.

Maintmaster MI: Making sense of every note, log and data point

Real manufacturing insight, powered by AI

What Maintmaster MI means for your teams

Maintenance

- Troubleshoot faster with context that points you in the right direction

- Cut down on repeat jobs by spotting recurring issues early

- Link recurring problems to asset care and preventive plans

Production

- Identify recurring loss drivers

- Prioritise fixes that deliver the biggest production gains

- Use patterns to guide planning and continuous improvement projects

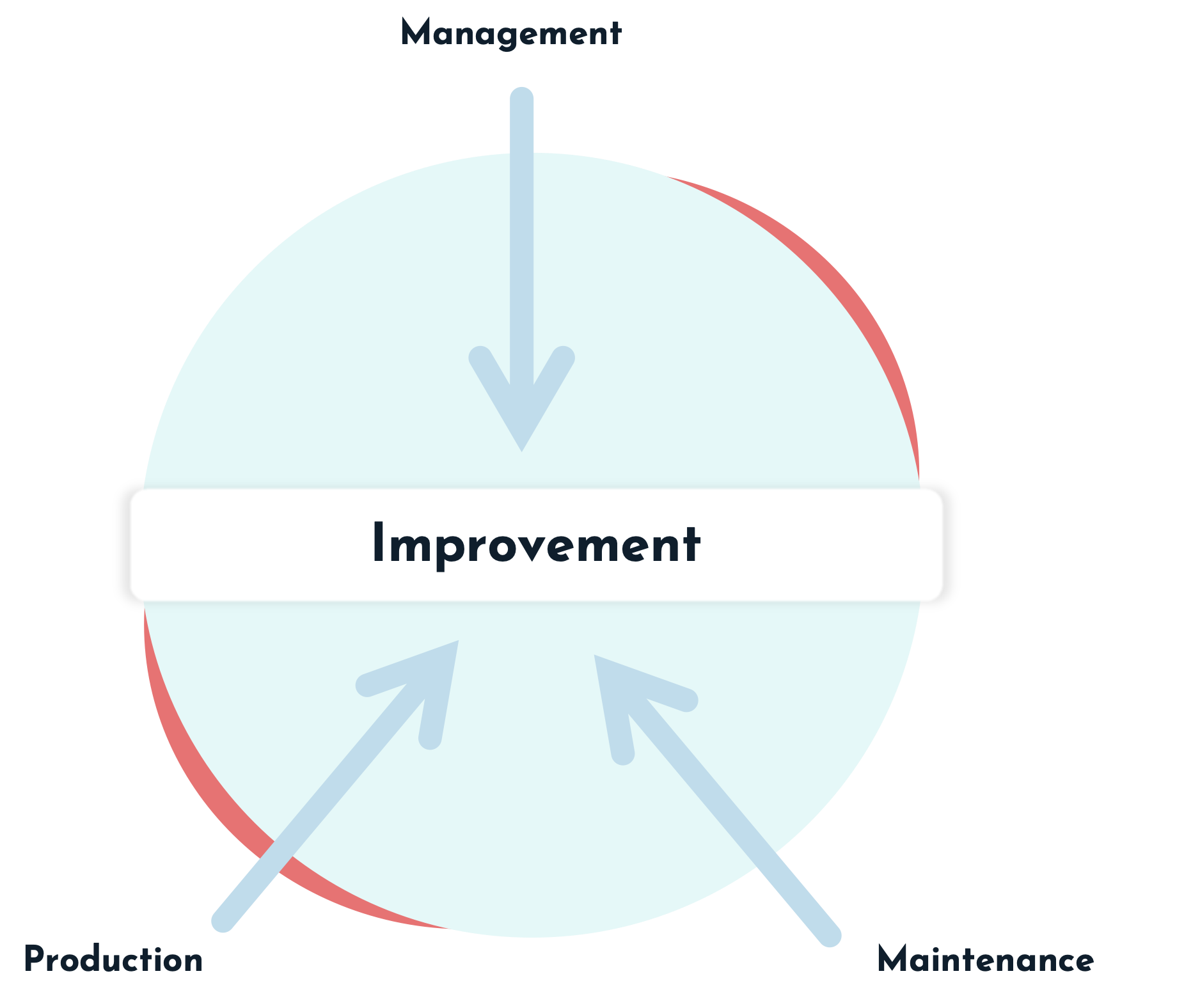

Make improvement part of everyone’s day

Operators see their notes turn into action, maintenance get clearer starting points, managers get priorities and see recurring trends across machines, lines and sites. Even without a CI team, Maintmaster MI makes improvement practical, shared and part of your everyday.

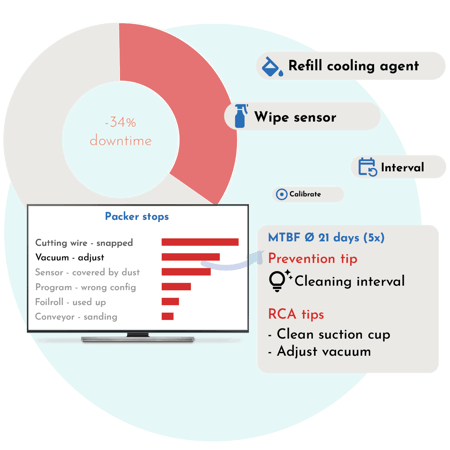

Turn repeat problems into smarter actions

Instead of chasing the same breakdowns shift after shift, Maintmaster MI shows the patterns behind them. Guided by past actions, it helps teams tackle the causes rather than just the symptoms so every job moves you forward instead of in circles.

See other CMMS use cases

Production & Maintenance Allignment

Boost uptime and efficiency with seamless alignment between maintenance and production.

Maintenance Alerts & Analysis

Identify issues early, prevent unplanned downtime, and move from reactive to proactive maintenance.

Audits & Compliance

Digitise maintenance, ensure compliance, and stay audit-ready without slowing production.

Operator Maintenance

structure, scale, and optimise operator maintenance to boost efficiency and maximise plant availability.

IoT Sensors

Monitor equipment conditions in real time with pre-configured gateways and sensors that integrate seamlessly with your CMMS. Simple to set up and ready to use.

See other OEE use cases

Preventing Unplanned Downtime

Spot downtime as it happens, uncover root causes fast, and prevent disruptions before they hit your targets.

Performance Benchmarking

Create one version of the truth across all sites, reveal hidden losses, and drive measurable improvement.

Production Monitoring

Supporting CI Projects & Teams

One source of truth for every team, turning data debates into measurable results on every shift.

Improving Changeover Efficiency

Make every changeover repeatable, efficient, and a driver of continuous improvement.

Teams & Visual Performance Data

Clear, real-time insights that keep every shift aligned and prevent small losses from becoming big problems.

MI + OEE: From root cause to suggested actions

OEE shows you downtime and losses. Maintmaster MI builds on that by adding the detail from operator notes and shift comments, giving teams a deeper understanding of why losses happen and where to focus first.

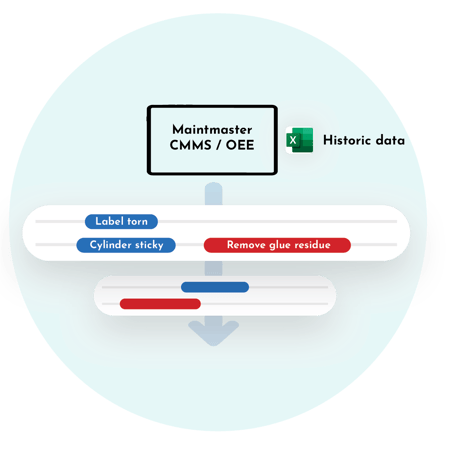

MI + CMMS: From work orders to what works

CMMS records the who, what and when of every job. Maintmaster MI makes sense of the unstructured notes around those jobs revealing recurring issues and highlighting fixes that worked before, so teams spend less time guessing and more time solving.

MI + CMMS + OEE: One connected view

MI adds what's missing - the details buried in notes, shift comments and work orders. That means fewer blind spots in work requests, clearer information passed between production and maintenance and a clearer record of what really happened and what solved it.