Increase in total output

Find your bottleneck. Recover lost output.

More machines aren’t always the answer. Maintmaster OEE reveals where time and output are lost — helping you recover hidden capacity through better visibility, not bigger budgets.

Why teams use Maintmaster OEE

See where time

is really lost

Live visibility into stoppages, speed losses and quality issues helps you pinpoint constraints and act fast.

Improve performance shift by shift

Standardise best practices, reduce variability and enable consistent performance across teams and products.

Protect throughput with data-driven decisions

Use one source of truth to align teams, prevent downtime and justify changes — without guesswork.

From daily tasks to daily improvement

Before

Guesswork without clarity

Without live data, bottlenecks are debated not diagnosed.

Shift reports come too late, and teams operate on instinct, not insight.

Action

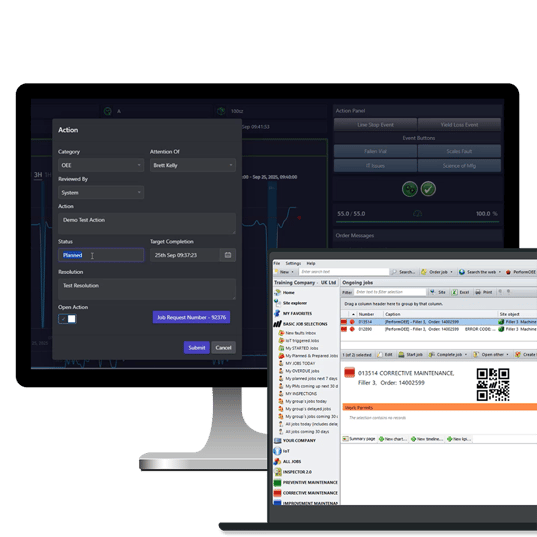

Monitor production in real time

Maintmaster OEE turns availability, performance and quality into live, visible metrics.

Dashboards, SIC reviews and digitally assignable notes empower action mid-shift, not after the fact.

Result

Clear bottlenecks, increased output

Teams respond in the moment. Performance gaps close.

Capacity is unlocked through targeted action, not new assets.

Live, shared and actionable —

production monitoring

that works

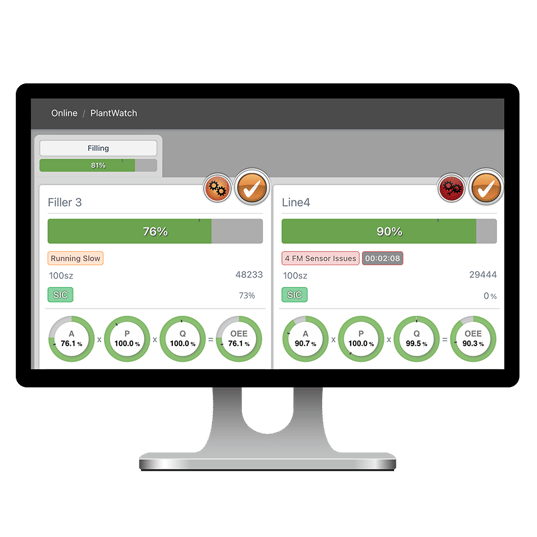

Act on live line visibility

Know immediately which lines are running, slowing or stopped. Compare actual vs target speed rate and track quality issues as they happen.

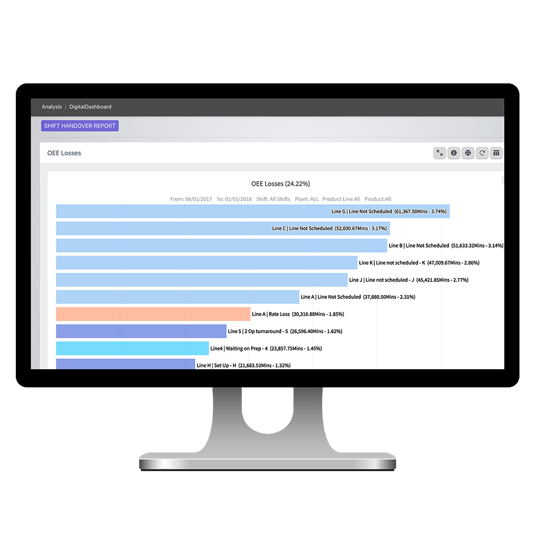

Identify the real bottleneck

All losses are categorised, visualised and ranked. Use pareto charts and historical comparisons to address the biggest constraints first.

Align production and maintenance

Send early alerts to maintenance when assets slow down. Highlight training gaps and improve shift consistency based on real operator behaviour.

Production monitoring with proven payback

OEE lift across monitored lines

Reduction in unplanned downtime

"It’s made our morning meetings more proactive and our teams more data-driven — people now come with answers, not just problems."

- Shabaz Mahmood, Manufacturing & Engineering Manager, Science in Sport

"MaintMaster OEE allows us to go from problem to solution faster — with data that helps us make the right call the first time."

- Eric Steer, VP of Operations, Chairmans Foods

Before and after

Maintmaster OEE

The old way

Reactive, incomplete, inefficient

- Outdated reports and analysis

- Conflicting data from different systems

- Unlogged micro stops

- Overtime decisions based on gut feel

The new way

Live, shared, targeted

- Real-time monitoring and logging

- One version of the truth

- Actionable insights per shift

- Data-backed planning and interventions

Take control of your production with Maintmaster OEE

Real-time insights into every machine, every shift

Our OEE software gives you live data straight from the shop floor, helping you spot inefficiencies, resolve issues quickly, and bring your team together. From operator actions to strategic decisions, it’s the data backbone that drives improvement across your entire operation.

See other OEE use cases

Preventing Unplanned Downtime

Spot downtime as it happens, uncover root causes fast, and prevent disruptions before they hit your targets.

Performance Benchmarking

Create one version of the truth across all sites, reveal hidden losses, and drive measurable improvement.

Supporting CI Projects & Teams

One source of truth for every team, turning data debates into measurable results on every shift.

Improving Changeover Efficiency

Make every changeover repeatable, efficient, and a driver of continuous improvement.

Teams & Visual Performance Data

Clear, real-time insights that keep every shift aligned and prevent small losses from becoming big problems.

OEE & AI

Turn production data into clear, actionable insights. Helping teams spot losses, fix root causes, and boost performance every shift.

Learn moreFrequently asked questions

- How is production monitoring different from standard reporting?

-

Traditional reporting is often reactive, based on shift-end or next-day summaries. Maintmaster OEE’s production monitoring gives you a live view of availability, performance and quality.

This means production teams, engineers and managers see issues as they happen and can respond immediately, something paper logs or static reports can’t deliver.

- Will operators see this as extra work or resist using it?

-

No. Maintmaster OEE is designed to be quick and visual. Operators only confirm downtime reasons or add short notes, which takes seconds. In return, they gain clarity on how their shift is performing and can see the impact of their actions in real time, which helps build engagement rather than resistance.

- How does production monitoring data integrate with our existing systems?

-

Maintmaster OEE can be deployed as a stand-alone monitoring solution or connected to ERP,MES or PowerBI systems where required. It uses existing machine signals and some operator input to deliver live performance data and this data can be linked into your wider systems without disrupting existing workflows.

- What kind of training is needed to use production monitoring effectively?

-

The system is designed to be intuitive, with role-based dashboards and colour-coded visual indicators. Most operators and supervisors need only brief onboarding to start logging downtime reasons and using the live dashboards. We provide both standard user and super user training. We also operate a “train the trainer” approach.

- How quickly can production monitoring show measurable results?

-

Most sites start with one line or production area and are live within weeks. Because production monitoring reveals hidden stoppages and performance variation immediately, opportunities for improvement are visible from day one. Many customers act on these insights within the first month and see tangible performance gains quickly.