OEE improvement <6months

Turn data into daily CI decisions

With shared real-time data, Continuous Improvement becomes daily practice. Maintmaster OEE gives teams clear visibility to focus on the right problems and prove results faster.

Why teams use Maintmaster OEE

One Version of Truth

Standardised data and shared dashboards replace guesswork and arguments.

Focus on what matters

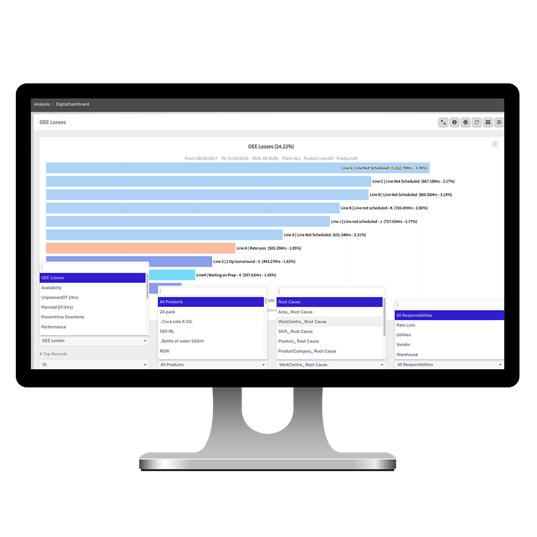

Live losses and trends show where to focus CI effort for maximum impact.

Prove and sustain gains

Measure the effect of actions and lock in improvements with alerts and targets.

From chasing data to driving outcomes

Before

The problem isn’t effort. It’s consistent data

CI teams work hard but often from different data sets. Production has one view, maintenance another. Meetings become debates. Time is lost reconciling numbers instead of solving problems, and it’s difficult to prove what really changed.

Action

Clear data. Clear priorities. Faster results.

Maintmaster OEE gives everyone the same live performance view. Losses are coded consistently, root causes are captured at source, and trends are visible daily. CI and operations align on the same facts and intervene during the shift — not after.

Result

A visible shift in culture

Teams move from opinion-based discussions to fact-driven decisions. SiS gained +10% OEE in six months by exposing short, frequent stops. Chairman Foods cut unplanned downtime by 42% by focusing CI on real loss patterns. Decisions get faster. Results become repeatable.

See clearly.

Act confidently.

Improve continuously

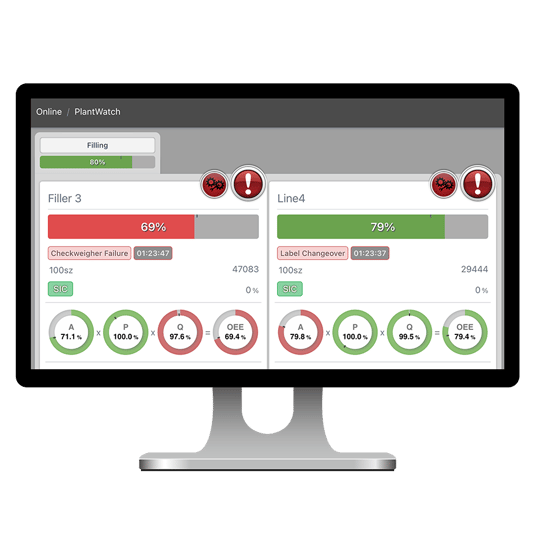

Live visibility, shared focus

Know instantly which lines are falling behind target. Real-time OEE and APQ updates allow teams to react before problems escalate.

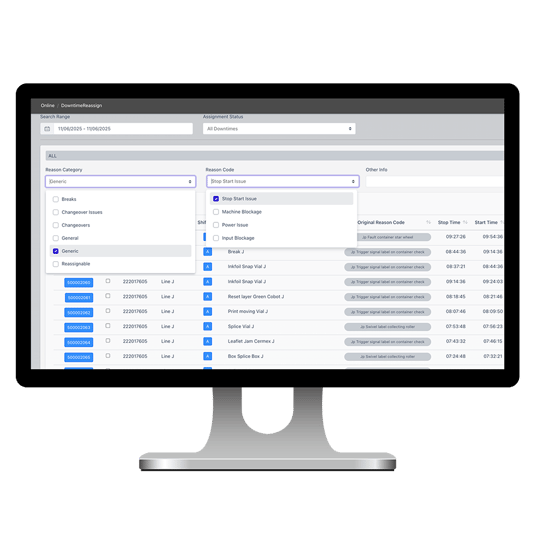

Root cause clarity

Automatic event capture and operator input build a reliable data set for analysis. CI teams can identify recurring issues and stop fixing symptoms.

Standardise the language of loss

Standardised loss definitions ensure every CI project starts from the same facts. Compare sites, track progress, and prove impact without reconciling data.

Prove what works

Filter by product, shift, machine or responsibility. Track the effect of CI actions over time in minutes, not weeks.

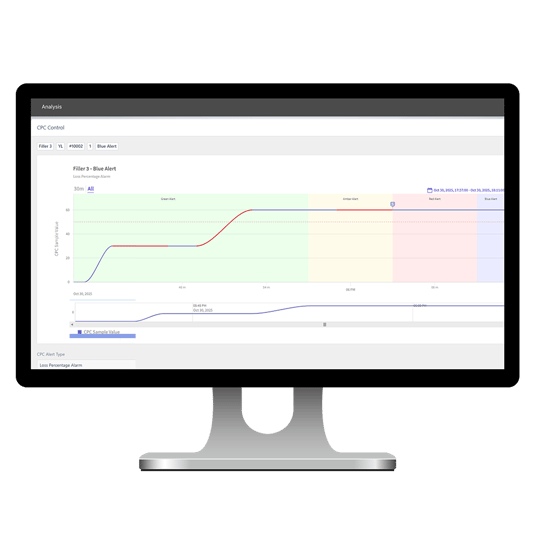

Keep gains locked in

Set targets for OEE or specific losses. Get notified when values drift, so improvements don’t fade.

Proven results — Data-driven gains in OEE and uptime

Reduction in unplanned downtime

Reduced changeover variance

Reduction in idling and short stops

"Quality is a key element of our process and Maintmaster OEE gives us strong insights as well as early warnings when these types of issues arise."

- CooperVision UK

"Maintmaster OEE is now fully integrated into our daily operations… helping us deliver projects and train our teams on operational problem solving.”

- Müller Milk & Ingredients

Before and after

Maintmaster OEE

The old way

Opinions and overhead

- Inconsistent data and late reports

- Meetings that debate, not informed decisions

- Hard to prove what worked

The new way

Facts and follow-through

- One version of the truth, live data

- Priorities aligned in minutes

- Fast decisions based on live data

- Gains evidenced and sustained

Take control of your production with Maintmaster OEE

See how data can drive your continuous improvement

From shared data to measurable impact, Maintmaster OEE gives every team the visibility and confidence to focus on what really drives performance.

See other OEE use cases

Preventing Unplanned Downtime

Spot downtime as it happens, uncover root causes fast, and prevent disruptions before they hit your targets.

Performance Benchmarking

Create one version of the truth across all sites, reveal hidden losses, and drive measurable improvement.

Production Monitoring

Spot downtime as it happens, uncover root causes fast, and prevent disruptions before they hit your targets.

Improving Changeover Efficiency

Make every changeover repeatable, efficient, and a driver of continuous improvement.

Teams & Visual Performance Data

Clear, real-time insights that keep every shift aligned and prevent small losses from becoming big problems.

OEE & AI

Turn production data into clear, actionable insights. Helping teams spot losses, fix root causes, and boost performance every shift.

Learn moreFrequently asked questions

- How long to see results?

-

Actionable insights usually appear within days; measurable improvements typically within weeks, depending on focus.

- Do we need dedicated analysts?

- No. Dashboards and reports are clear and self-serve; most teams need minimal training.

- Can it match our categories and shifts?

- Yes. You define loss types, shifts, products, equipment, breaks — reflecting real operations.

- Is it only for big sites?

- No. Works for single lines and multi-site enterprises alike.

- Will CI slow operators down?

-

No. Most data is automatic; operator inputs use quick drop-downs and touch-friendly screens.