OEE improvement in <6 months

Spot losses and hit production targets

Real-time OEE software for smarter production decisions

Improve your OEE with expert guidance

We’ve spent 20+ years helping manufacturers reduce downtime and increase performance.

Trusted by world leading manufacturers

Built for the realities of your factory floor

Easy adoption

Fits how production teams work - easy for operators to use, trusted by managers and part of the daily rhythm on the shop floor.

Deeper insights

Every downtime, performance change or quality issue is captured in real time - giving you reliable insight into causes and actionable improvements.

Made for production

Designed by manufacturing experts who understand the pace, pressure and priorities of plant life. Software that works as hard as your team does.

Instant visibility for

better control

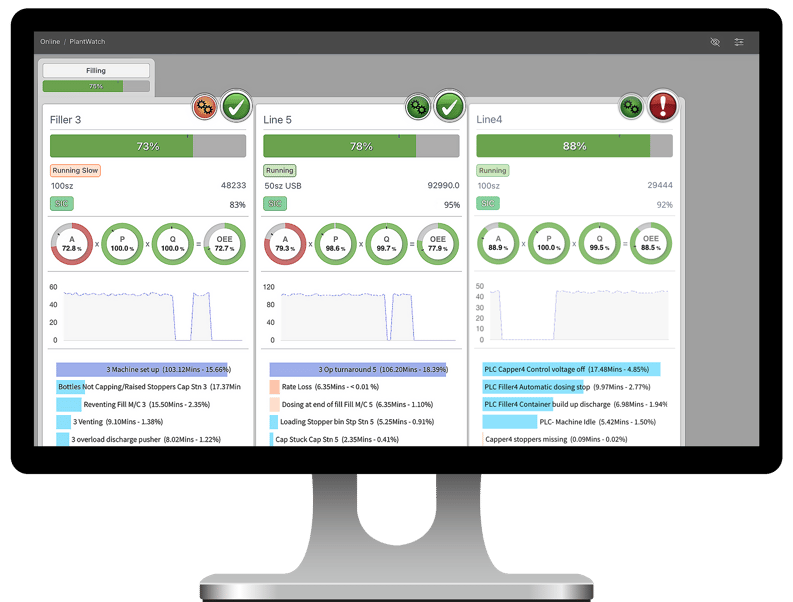

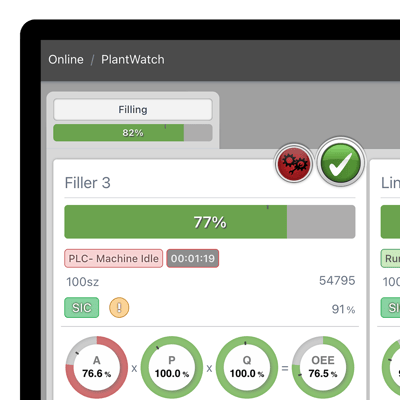

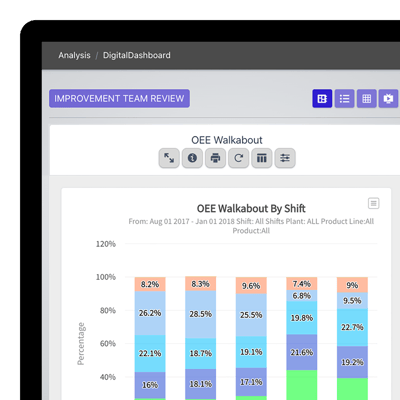

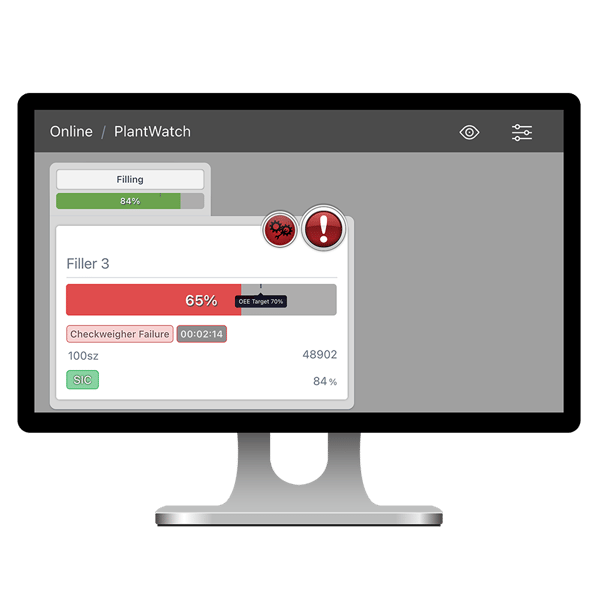

Plant-wide performance on one screen

See OEE, availability, performance and quality for every line and work centre in a single view. Compare lines and shifts, spot the bottleneck, and see if today’s production is on track against plan.

Turn shift-end surprises into action

Shift issues shouldn’t wait for reports. Maintmaster OEE shows where output is slipping right now, helping teams act fast and keep production running smoothly.

Connect every team to one shared view

Operators, engineers and managers work from the same live data — reducing delays, guesswork and confusion at shift handover.

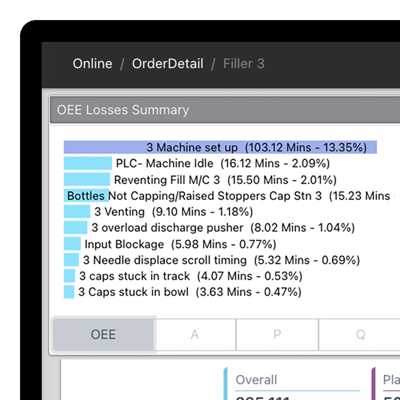

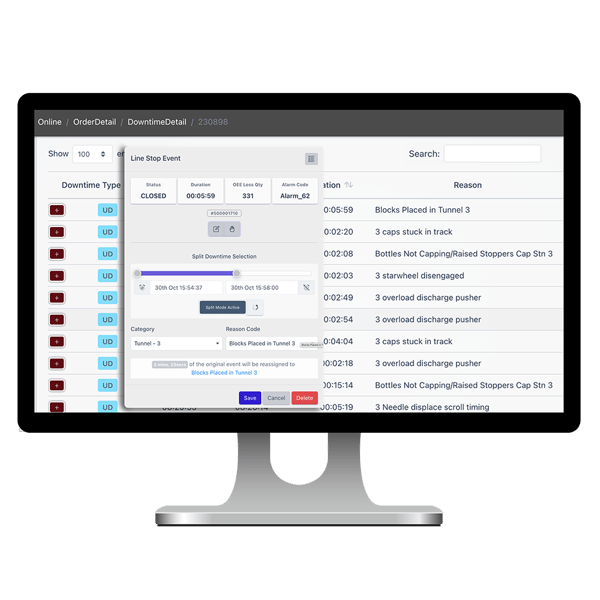

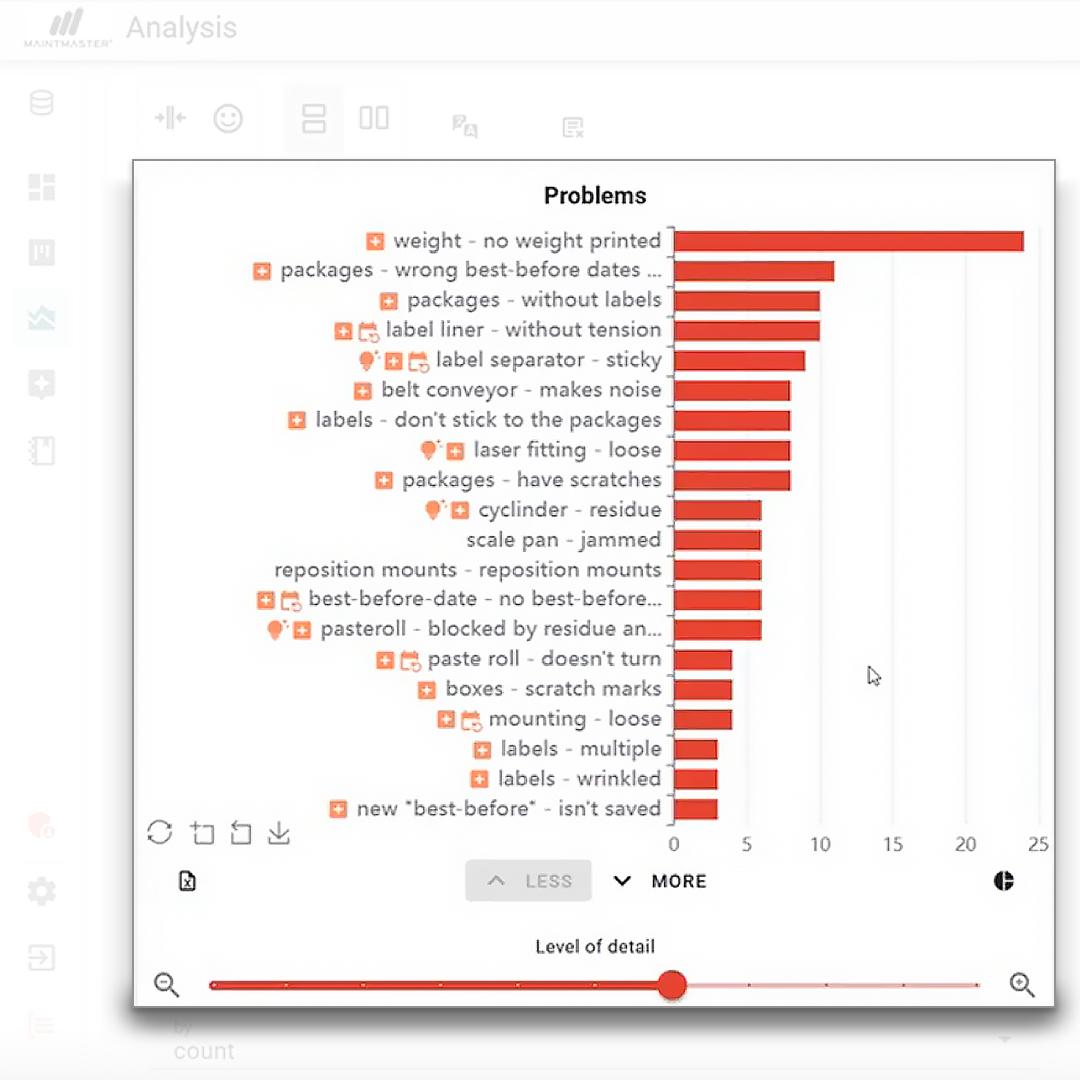

Turn blind downtime into visible causes

When downtime is logged as “machine stopped,” no one knows why it happens again. Capture every stop with reason codes and patterns so you fix root causes.

Move from opinions to facts

Opinions and rough estimates slow progress. Expose true losses and performance gaps so every decision drives visible results across your plant.

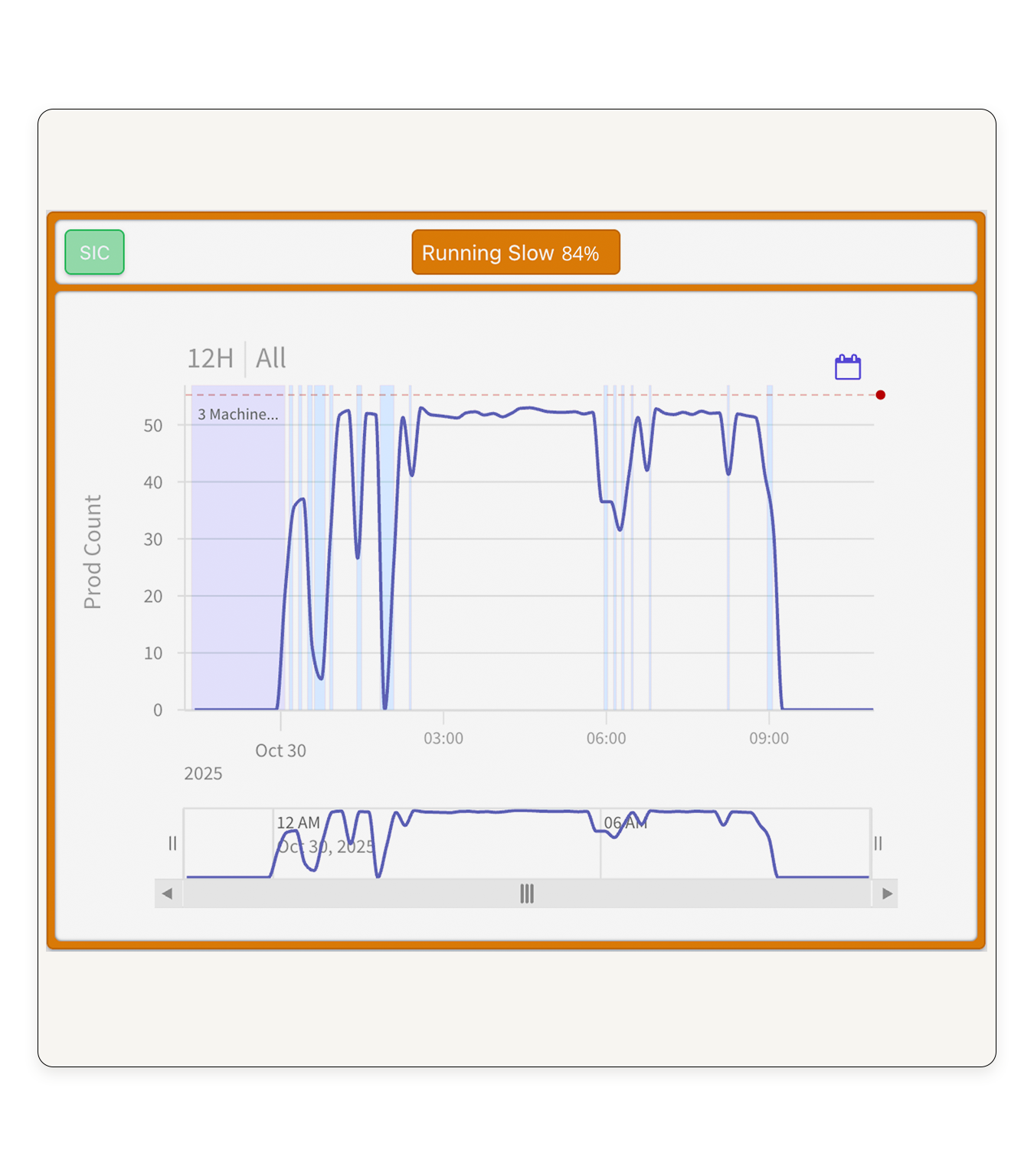

Stop reacting, start improving every shift

Without real-time loss tracking, every shift repeats the same problems. See live trends and performance gaps so teams adjust on the floor and keep improving every day.

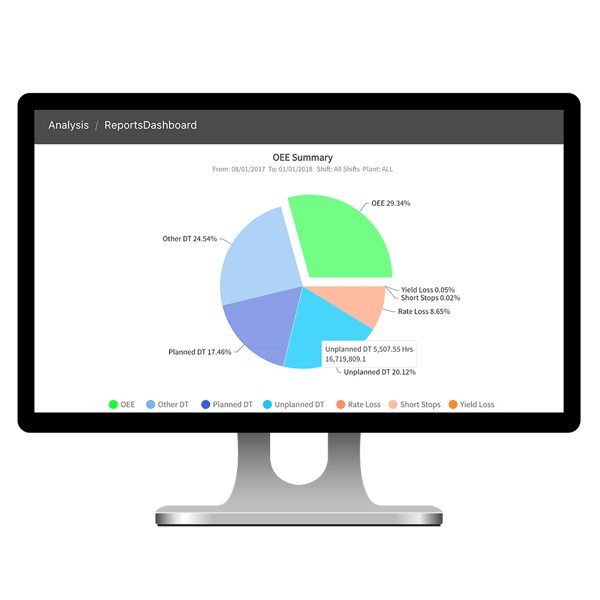

Detect. Analyse. Improve.

Do it all in one system - from live data to continuous improvement.

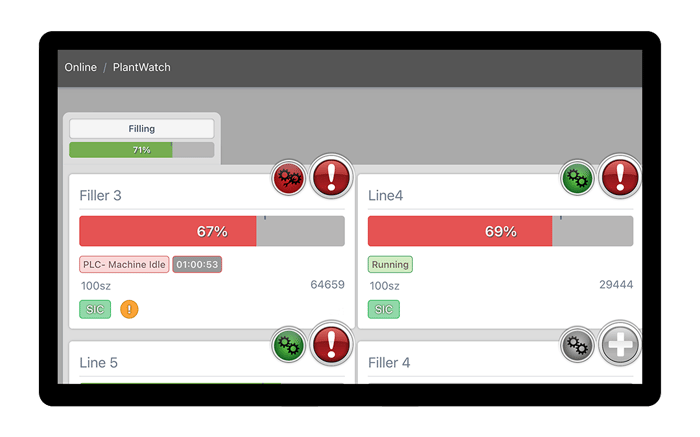

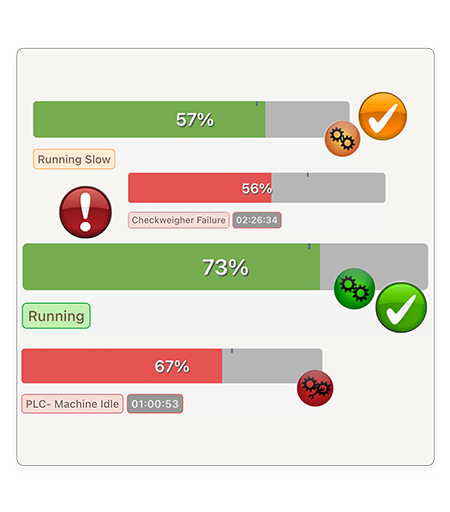

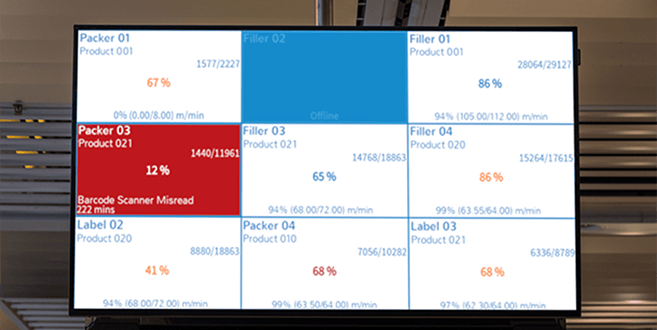

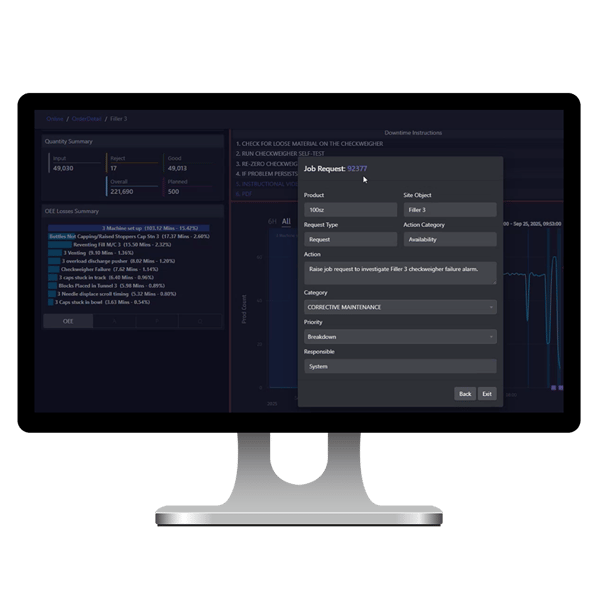

Live performance at each line

Track live production speed, OEE%, and downtime across every line and shift. View loss reasons as they happen so you can act before they grow into missed orders and overtime.

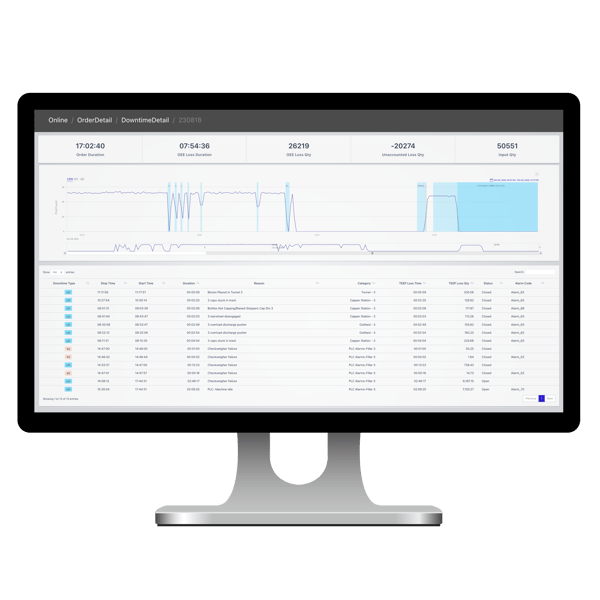

Find the real causes behind every loss

Capture and categorise every unplanned stop, speed loss, and quality failure. Drill down into the detail to identify repeat issues and remove uncertainty about where time is really lost.

Achieve lasting improvements

Turn data into action by comparing shifts, products, or full quarters. Monitor how changes impact performance and build a continuous improvement culture driven by evidence, not assumptions.

Real-time production monitoring

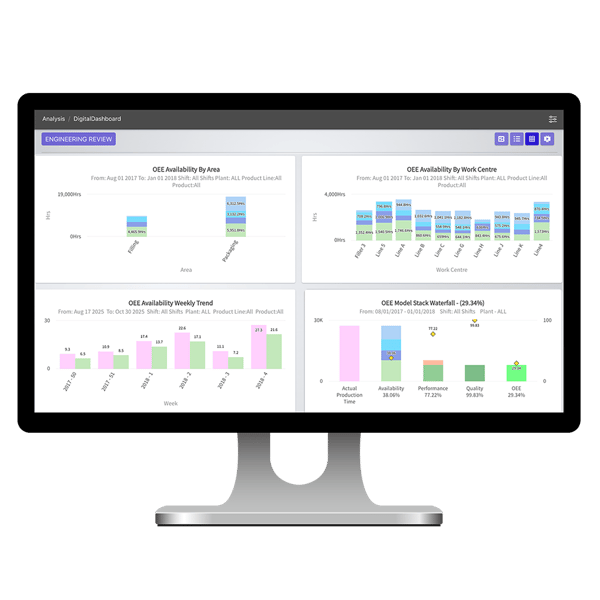

Full visibility across every line, every shift

Spot issues before they grow

Live dashboards highlight OEE, downtime and status for every line and work centre, with clear alerts when performance drops. Production, maintenance and team leads see which lines need attention first, so they can act before small issues cut into output.

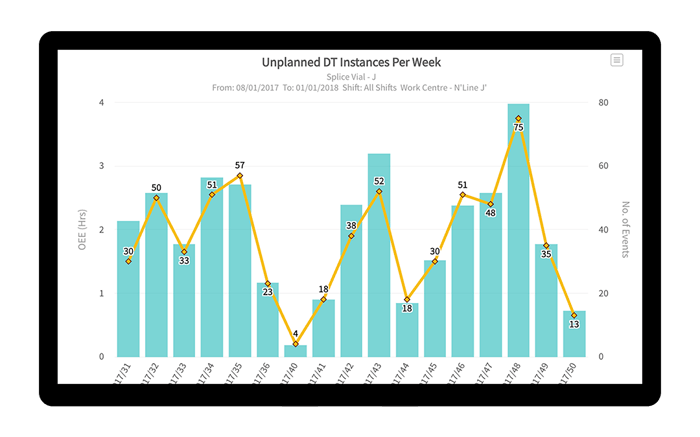

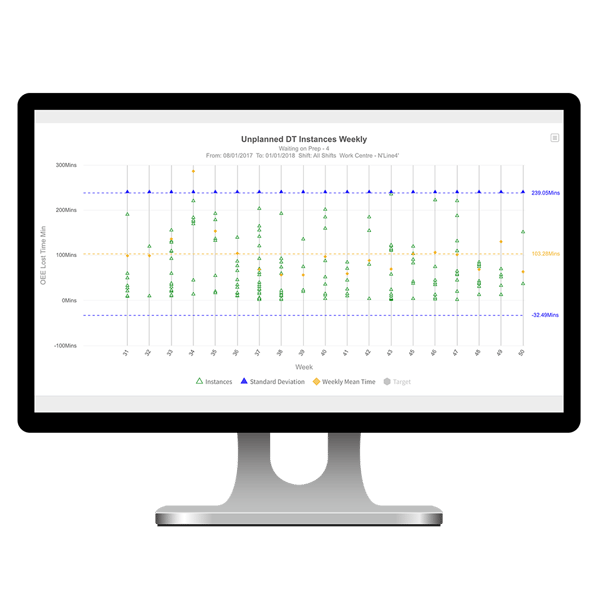

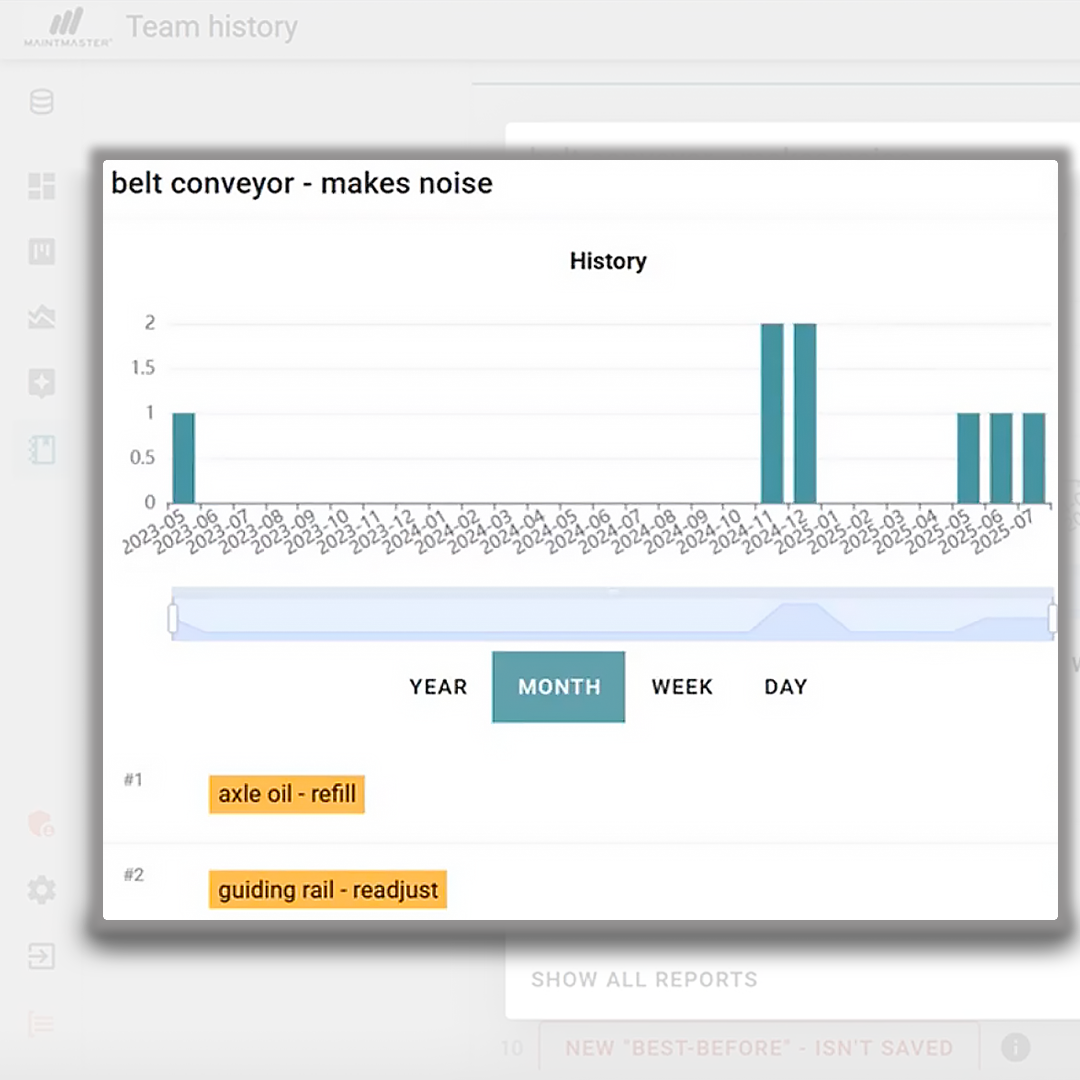

Spot downtime patterns

Analyse downtimes by week, shift or work centre. See how often events occur and how they trend over time, so you can target the biggest losses first and track the impact of improvement work.

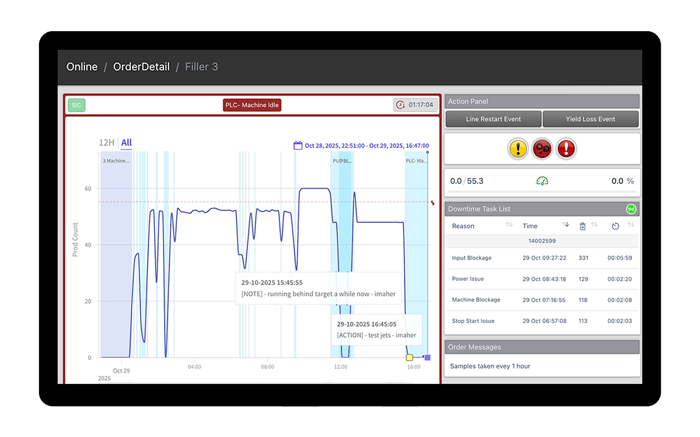

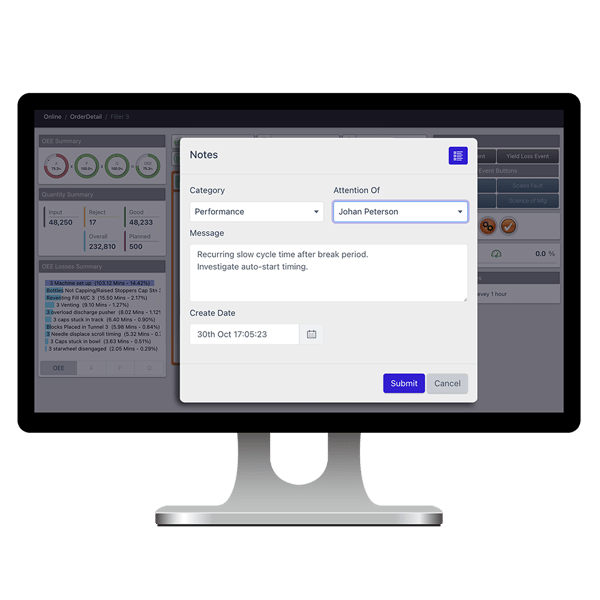

Update teams instantly

Share notes, issues and actions from the line. Tasks are tagged to individuals with time stamps, so operators, engineers and managers can see what has happened, who owns the next step and what is still open.

Lets break it down

Live line status at a glance

See the shift, minute by minute

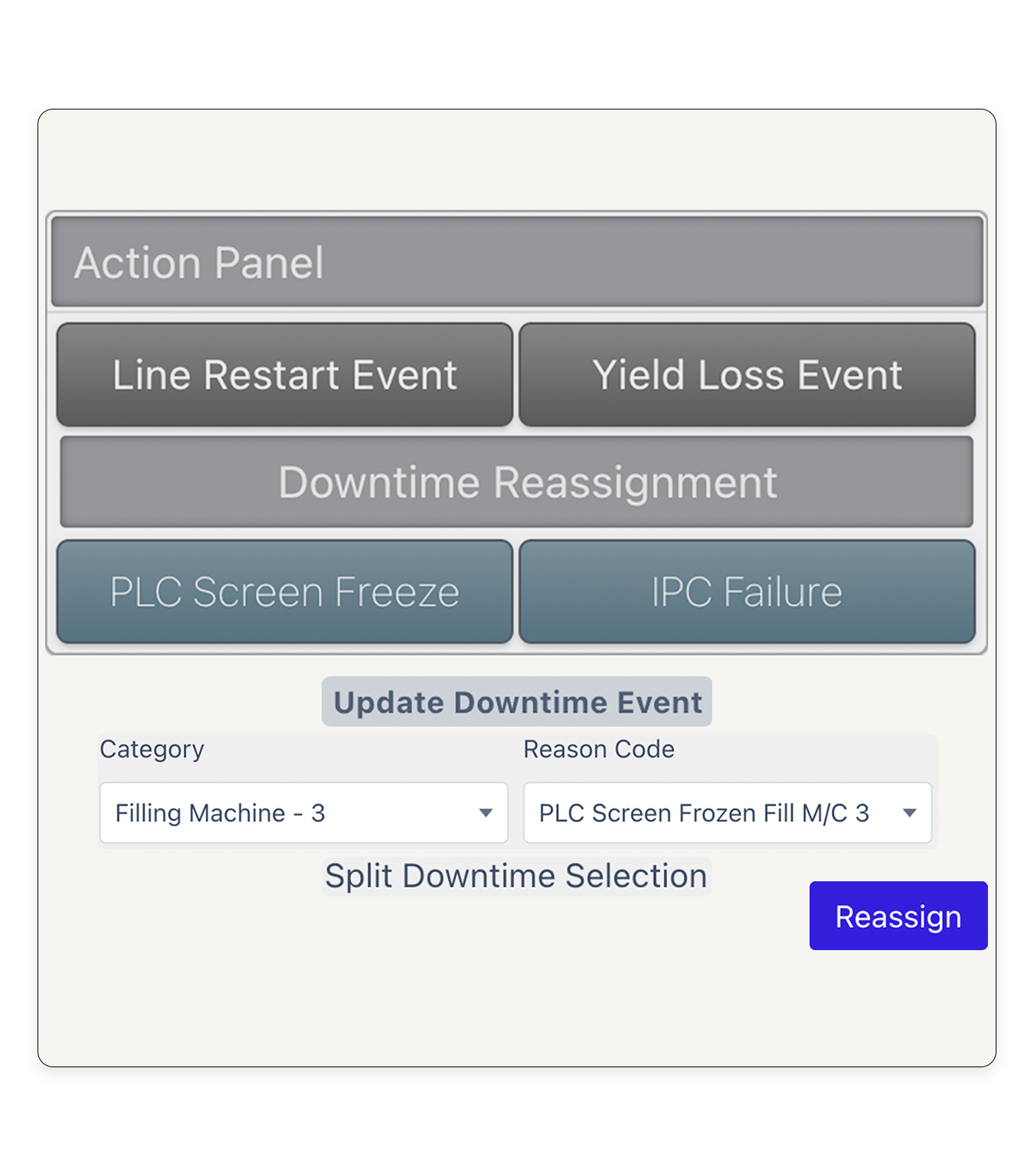

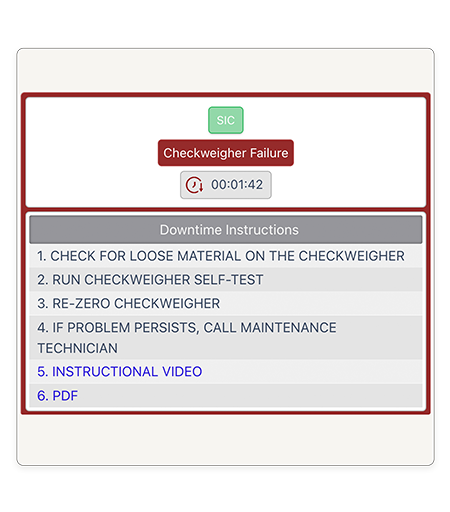

Act fast, right on the line

Let operators reassign downtime reasons, view work instructions or videos, and track actions on-screen. A live timer shows how long lines are stopped.

Fix issues with on-screen help

Attach PDFs, videos, or SOPs to downtime reasons so operators get guidance without leaving the display, cutting delays and boosting first-time fixes.

Real results from real manufacturers

From reduced losses to improved performance, MaintMaster OEE helps manufacturers make smarter decisions with real-time visibility and actionable data. Our customers use it to increase uptime, hit production targets and take control of their efficiency goals.

Explore their stories to see how operations teams like yours are using MaintMaster OEE to turn data into measurable impact.

OEE gain by improving changeover efficiency

We now know the moment something goes wrong. The result? Problems don’t linger and past improvements aren’t lost.

reduction in downtime with OEE-driven continuous improvement

This system is so visual, you can see the bar chart change as the day progresses. The CI team uses it daily for running reports, reviewing root cause analysis and looking at trends.

OEE gain sing insights from real-time data

If you’re running blind, you’re always reacting. Data is what turns you from firefighting into leading. Maintmaster OEE is our daily driver. It powers a lot of our decisions.

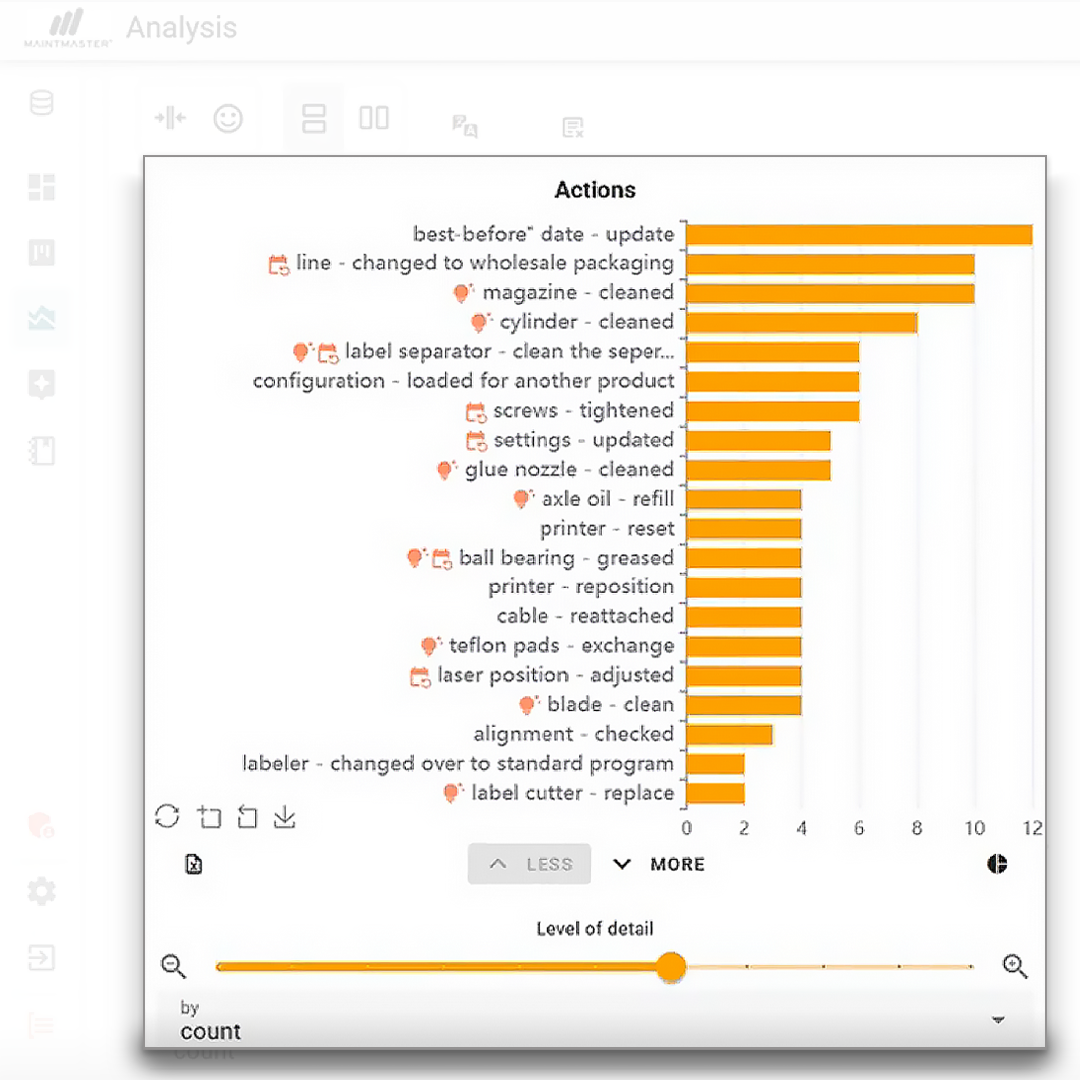

Downtime and loss analysis

The instant way to reveal root causes

Capture losses automatically

Collect downtime data from connected machines and add operator input for cause and duration for accurate tracking of every event.

Analyse where performance slips

Use dashboards and reports to break down losses by line, shift or product, exposing the biggest drains on output and efficiency.

Warn teams before output drops

Set up alerts when lines slow or targets miss so teams react instantly instead of after the shift.

Reduction in unplanned downtime

Reduced changeover variance

Less idling and short stops

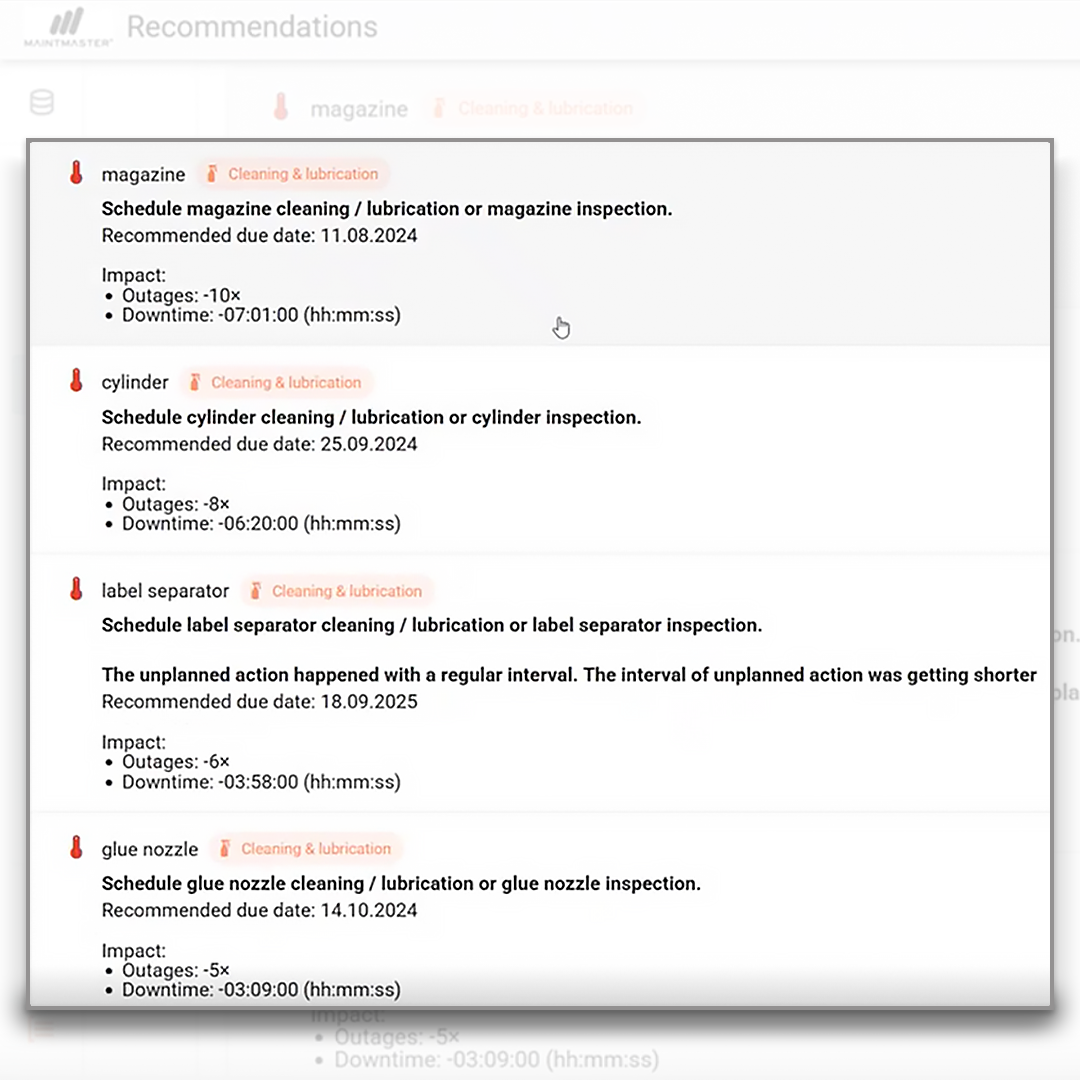

Continuous improvement

Your journey to performance gains

Find hidden opportunities

Drill through OEE, availability, and quality metrics to find the biggest causes of loss. Follow the data from line to shift and product until the next improvement is clear.

Assign action and lock in progress

Record notes, set owners and track completion to make sure gains stay permanent. With CPC (Continuous Process Control), when setup slips, you’ll know. CPC tools track speed, quality, and output, identifying changes fast.

Grow with a system that adapts

Expand from one line to multiple sites, add reports, and tailor dashboards as your improvement culture matures.

Visual factory displays

Real-time shop floor visibility

Display live performance where it matters

Track targets, speed, and yield with OEE, downtime, and quality data on large screens and handhelds to keep production on course throughout the shift.

Unite teams around one shared truth

Present production, quality, and maintenance data together so operators, engineers, and CI leads work from the same numbers with collaboration between shifts and departments.

Trigger action visually

Highlight breaches, slow runs or setup delays with clear visual alerts so your team responds faster and keeps output on course.

Stay connected everywhere

View the same live displays on mobile or remote dashboards to stay informed when you’re away with complete visibility across every site, shift, and team location.

The future of production

Powered by Manufacturing Intelligence

AI insight that drives smarter production decisions

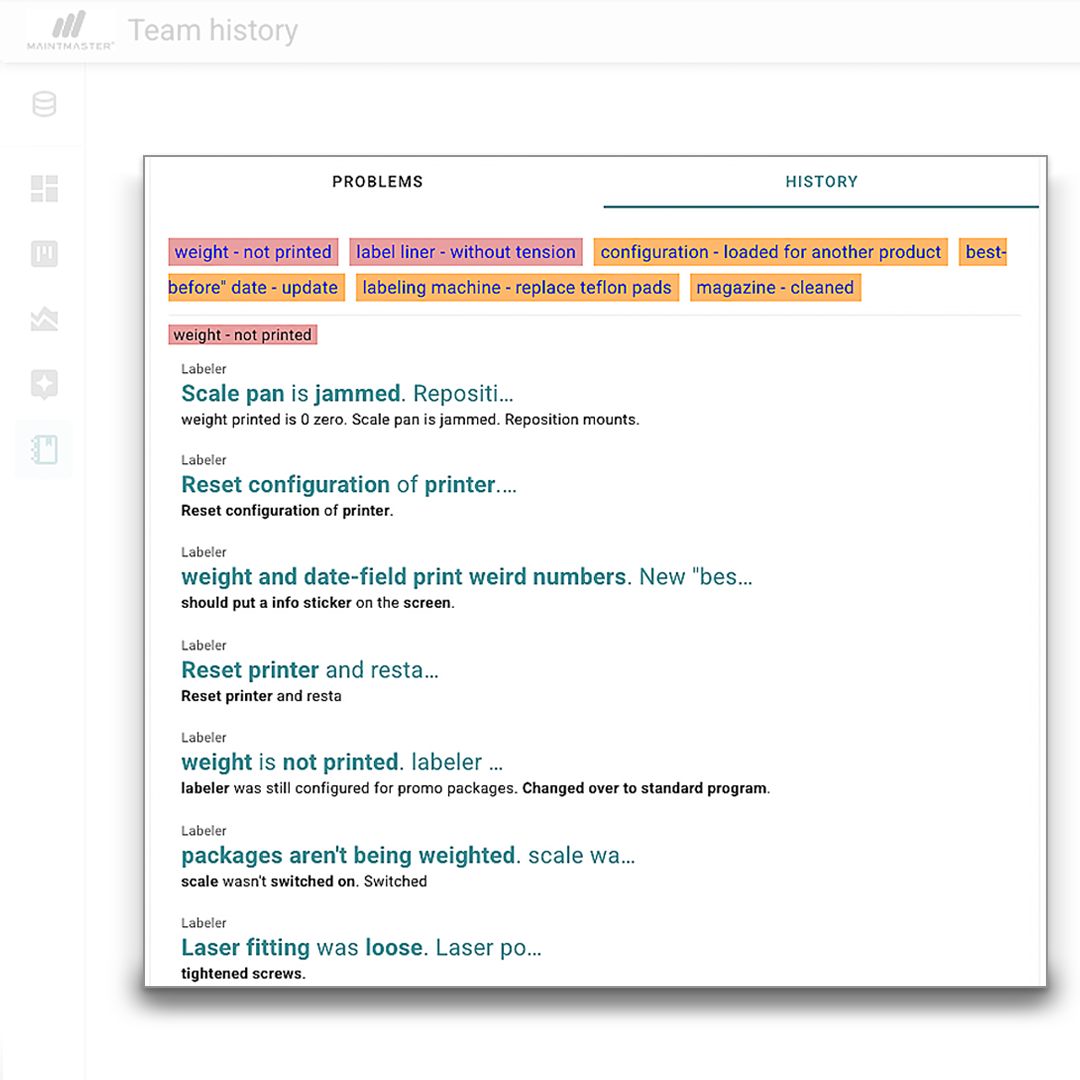

By combining OEE data with AI understanding of operator notes and shift comments, Manufacturing Intelligence gives leaders a deeper understanding of performance and loss.

Teams stay aligned, focused, and ready to act.

See missing patterns

Interpret notes like “mttr pump L3” or “sensor trippin” automatically with grouping for similar notes into recurring issues across shifts, lines, and sites.

Start fixes faster

Get recommended actions based on previous fixes for every problem so technicians can start repairs instantly.

Find problems easily

Cut trial-and-error with real guidance and proven solutions for quicker fixes, reduced downtime, and fewer recurring failures.

Address the highest impact issues

Structure and rank downtime drivers automatically, ready for Pareto analysis.

AI-ready your factory floor

Forget generic AI with Manufacturing Intelligence built and trained on real manufacturing data understanding shorthand, slang, and messy notes.

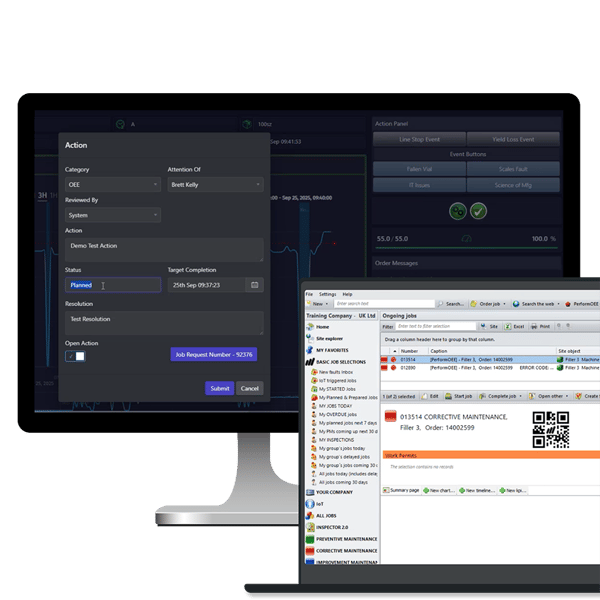

OEE + CMMS

Because production and maintenance belong together

Production and Maintenance in sync

Connect OEE with CMMS for seamless data exchange that keeps production and maintenance aligned. Data updates in real time across both systems, ensuring one accurate view - no duplication, no lag, no manual updates.

Detect downtime, generate jobs

Let Maintmaster OEE automatically generate jobs in the CMMS when it detects downtime events for faster response tips and high equipment productivity.

Make the integration yours

Customise the integration freely for your factory's needs, including rules and triggers matching your preventive, predictive, or mixed maintenance strategy.

Take control of your production with Maintmaster OEE

Your plant’s performance. Visible, measurable and improving.

MaintMaster OEE gives you real-time visibility into what's really happening on the shop floor — so you can catch downtime early, fix the root cause fast, and keep production on track. From operator actions to strategic decisions, it’s the data backbone that drives improvement across your entire operation.

Start seeing real OEE improvements from day one.

years of combined manufacturing experience

Implementations across 39 countires

supported by dedicated OEE team

See our OEE use cases

Production Monitoring

Spot downtime as it happens, uncover root causes fast, and prevent disruptions before they hit your targets.

Improving Changeover Efficiency

Make every changeover repeatable, efficient, and a driver of continuous improvement.

Preventing Unplanned Downtime

Spot downtime as it happens, uncover root causes fast, and prevent disruptions before they hit your targets.

Performance Benchmarking

Create one version of the truth across all sites, reveal hidden losses, and drive measurable improvement.

Teams & Visual Performance Data

Clear, real-time insights that keep every shift aligned and prevent small losses from becoming big problems.

Supporting CI Projects & Teams

One source of truth for every team, turning data debates into measurable results on every shift.

OEE & AI

Turn production data into clear, actionable insights. Helping teams spot losses, fix root causes, and boost performance every shift.

Learn more