Kraftringen is an energy company in Sweden with activities involving electricity grids, electricity sales, heating, cooling, gas, fiber and various contracting services. The headquarters are located in Lund and the majority of activities are placed in Lund, Lomma, Eslöv and Hörby. Operations are also firmly established in Northwest Skåne, Blekinge, Småland, Södermanland, Sjuhäradsbygden and on the plains of Västergötland.

Nowadays, the whole process is integrated

During the spring of 2016, Kraftringen migrated from T7 to MaintMasters updated maintenance software and, along with the transition, came the digitization of their process for handling work certificates. Previously engineers had to complete the forms manually, which they sent to the control room, which in turn completed its parts and then issued a work certificate confirming that work could begin. Nowadays, the whole process is integrated directly in the job in the maintenance system and can, therefore, be handled completely digitally. This delivers a major time advantage because engineers do not have to go to the control room to retrieve or submit forms. Since Kraftringen’s facilities are scattered across southern Sweden, they now save a lot of time traveling between facilities that previously required manual handling.

How does the digital management of the process work?

Five new tabs have been created on the job card:

- Risk assessment

- Work request

- Scheduled stop list

- Work in confined spaces

- Work certificates

Before starting work, a risk assessment is conducted that is consists of two parts. The first part addresses the risks inherent in the actual execution. This is either performed by the provider or the facility engineer, depending on the nature of the work. When the first part has been completed, the other sections of the work request are completed. The work request and risk assessment then progress in the system to operations, which is responsible for assessing the risks arising from the process. Operations creates a scheduled stop list and, if necessary, a connection list is also produced for electricity. If required, ‘Work in confined spaces’ may also be applicable. A work certificate is then issued, which means that it is OK to carry out the work. The work certificate must be renewed every day, unless otherwise agreed. It is always Operations that takes the decision about how long the work certificate will last.

When the work has been completed, the provider or facility engineer completes their part of the work request and work certificate and returns it to Operations, which in turn can restore the stopped parts and complete the work request. All signing for the various operations is carried out in the maintenance system, no ‘manual’ signatures are required. To this end, there are also a number of print-outs linked to the different forms, which can be printed out.

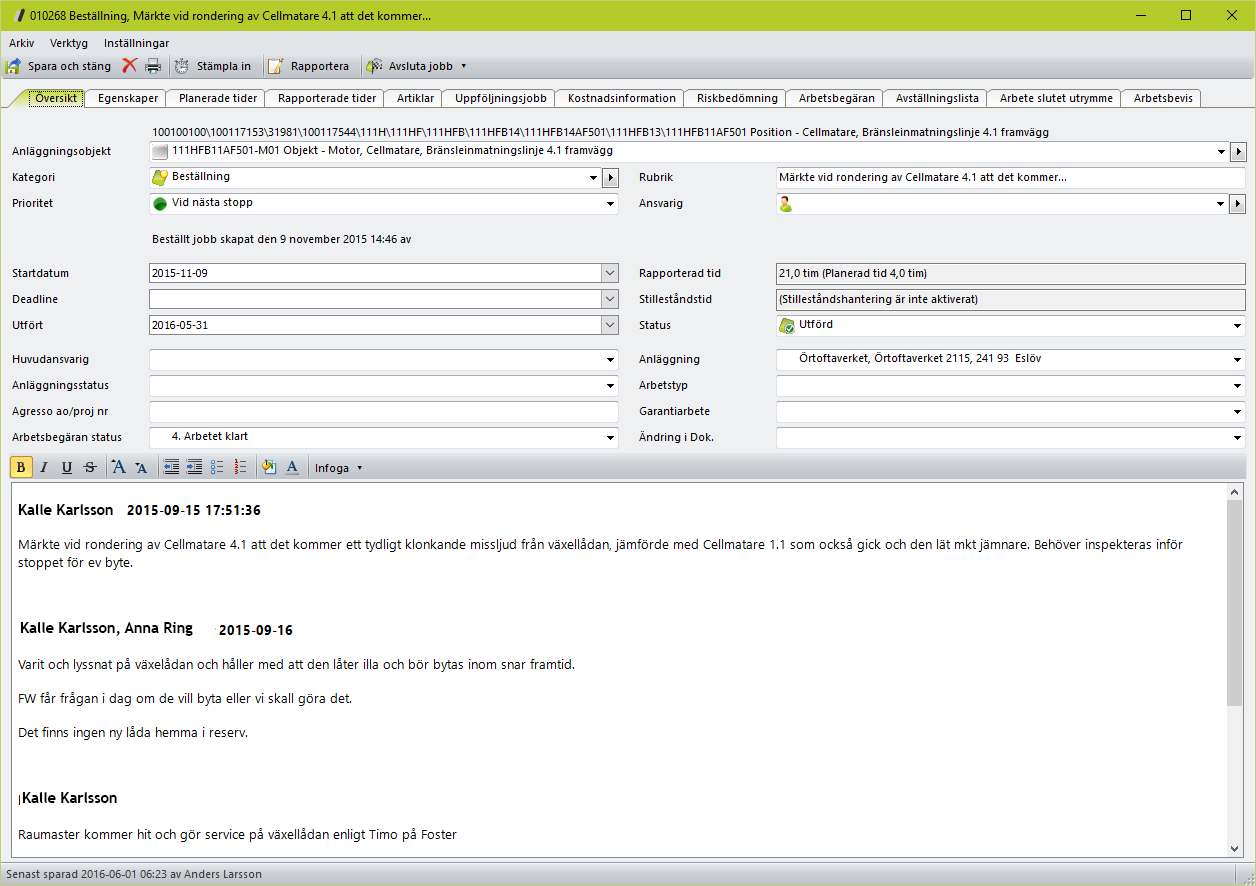

1. The custom job card with the added tabs: risk assessment, work request, scheduled stop list, confined space work and work certificates.

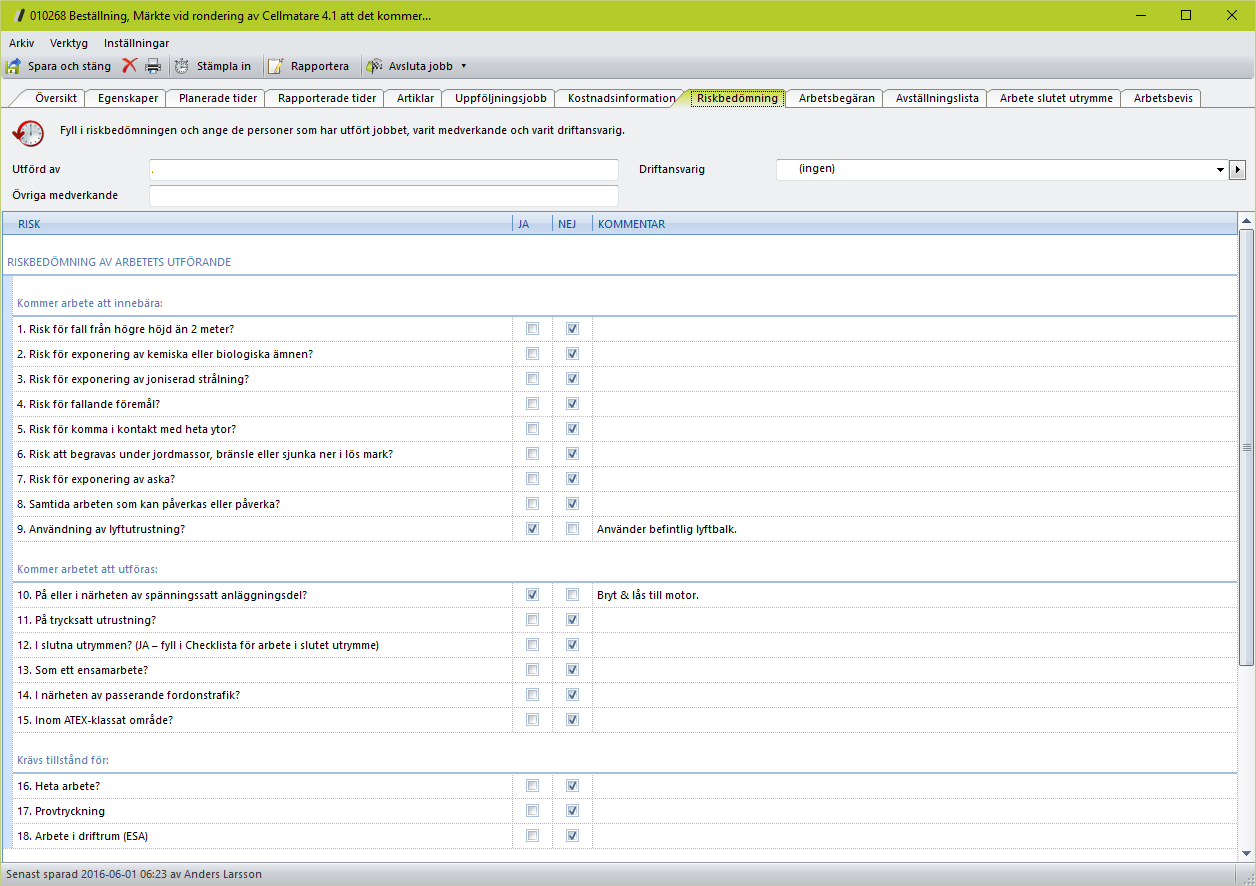

2. Risk assessment tab. Each line should be assessed with Comments where necessary.

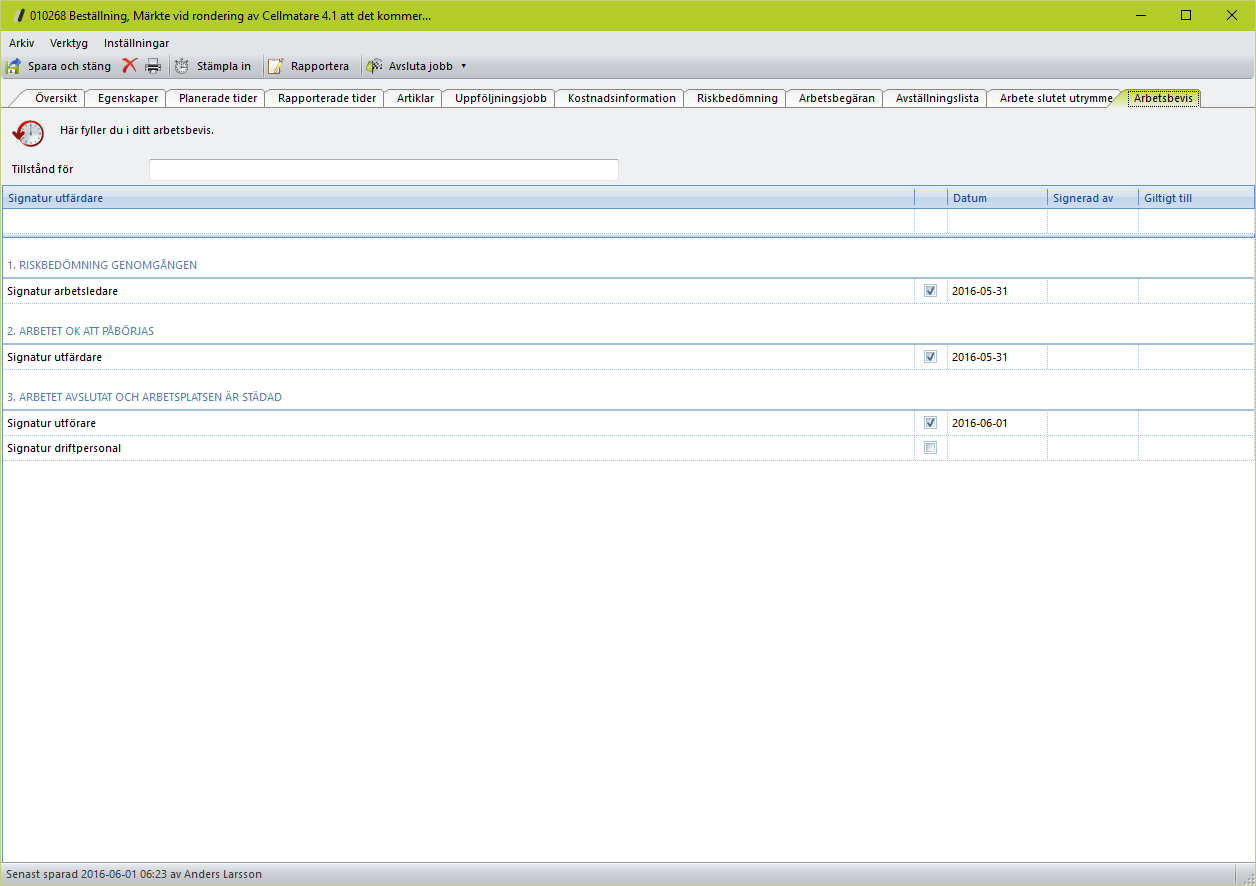

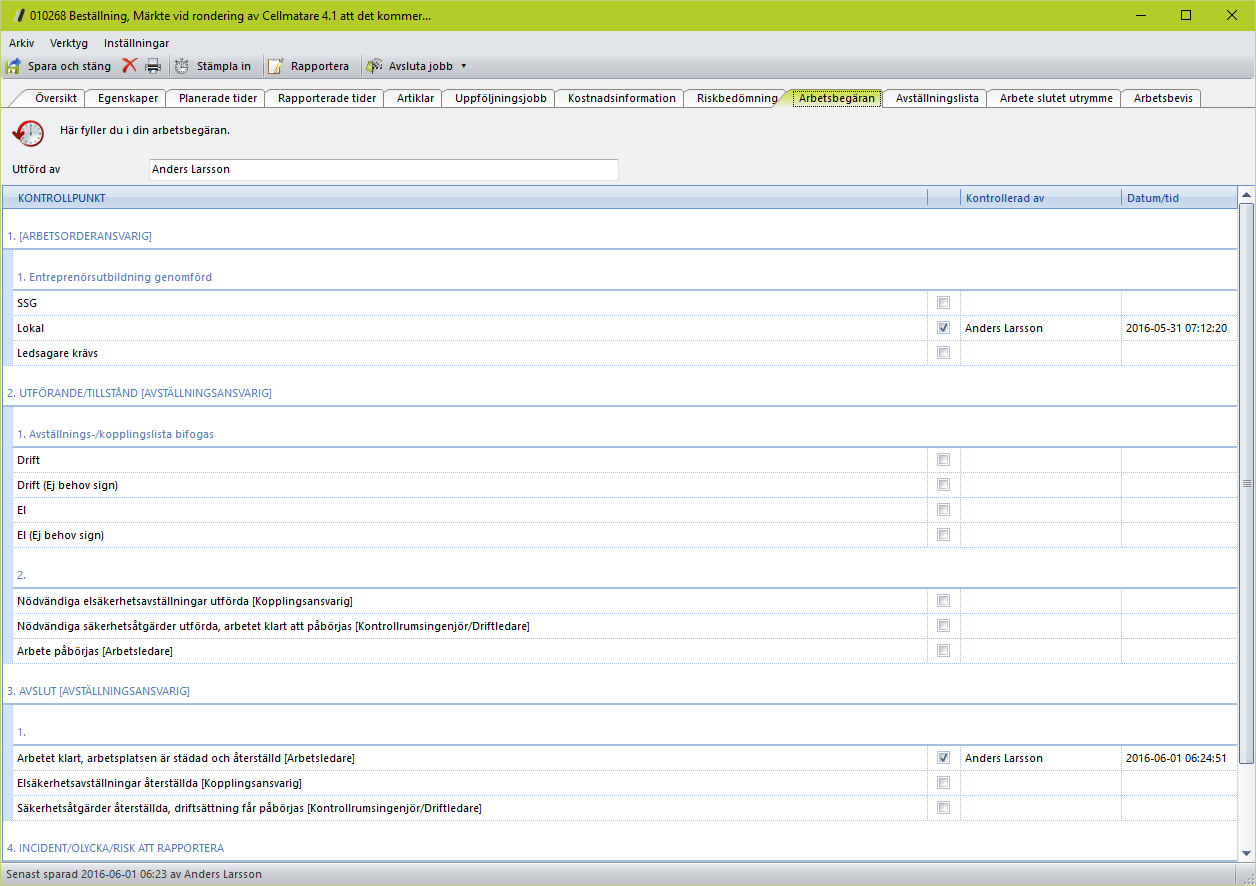

3. Work request tab. Displays the measures necessary to implement the job Work certificate tab.

4. Work can begin once the issuer has signed the work certificate.