- MaintMaster CMMS

- MaintMaster CMMS - Cost savings with Analysis & Reporting

Costs savings through one-click reporting with maintenance software

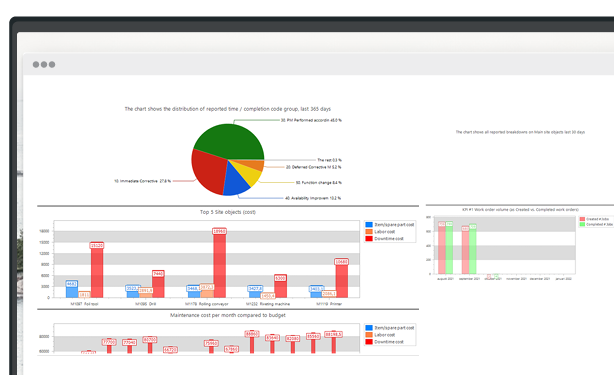

Create reports in a click and get insights from all information you can enter into MaintMaster, like which machine costs more to maintain than to replace.

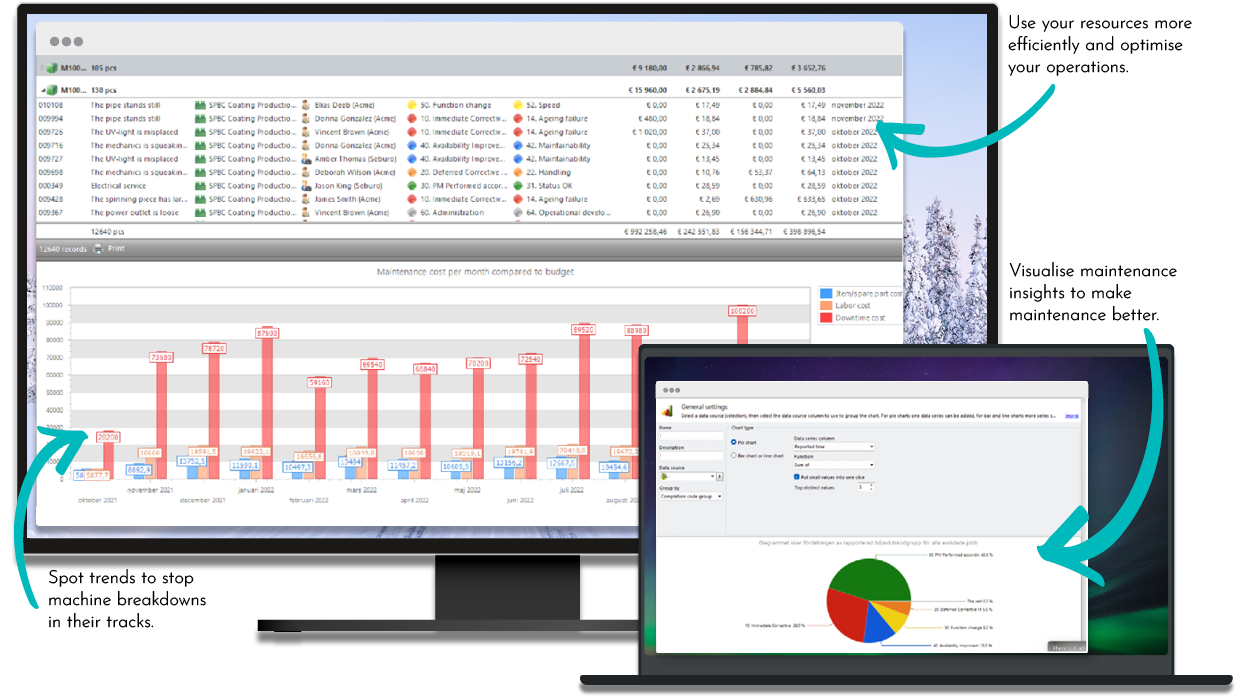

Visualise maintenance insights to make maintenance better

Analyse and report on maintenance data that helps your organisation understand your maintenance operations and identify key areas for improvement.

Identify bottlenecks and inefficiencies to make changes that improve your efficiency, helping you reduce downtime and production disruptions.

Improve productivity and save costs by visualising resource allocation, job orders, assets, and more. You can even combine data sources for new insights.

Spot trends to stop machine breakdowns in their tracks

Identify patterns or trends that indicate potential maintenance issues so you can act before breakdowns or other serious problems.

See why your machines have problems so you can reduce the risk of equipment failures and improve the reliability of your maintenance operations.

Analyse data on accidents and injuries to find potential safety hazards in your organisation, reducing the risk of accidents and injuries and improving your team's safety.

Use your resources more efficiently and optimise your operations

See your maintenance needs clearly by analysing task data, equipment, downtime, and other factors to know how to allocate your resources more effectively.

Tailor the key performance indicators and follow them daily to make smart long-term strategic decisions on equipment and operations.

Optimise your maintenance operations and achieve your goals by leveraging the power of data analysis and reporting for improved performance on equipment, facilities, and processes.

Effortless Analysis and Reporting for Maintenance Managers

Any statistics at any time? No problem.

Information that's entered in your maintenance system should be easy to use for statistics to give you the overview you want. And the support that's needed to make a decision. In this video, we show you how to create your own statistics.

Visualise important things.

Visualise important information directly at the start page in MaintMaster.

In this video, we show you how to do so.

GET THE INSIGHTS YOU WANT WITH MAINTMASTER CMMS

How Siva Group leveraged MaintMaster CMMS for organisational growth

BEWITAL's path to efficient operating processes,

Glas Trösch's Efficiency Boost in Maintenance

WANT TO KNOW MORE ABOUT OUR OTHER FEATURES?

Streamline Checklist Management on Mobile with Decision Support and Work Permit Administration for improved HSE Compliance and structure with MaintMasters Inspector.

Learn more about Inspections

Streamline your maintenance planning with scheduling tools that coordinate your maintenance organisation, prioritise critical tasks and reduce downtime.

Learn more about Scheduling

Introducing MaintMaster IoT Sensors - a plug-and-play add-on to your MaintMaster CMMS. These sensors are designed to detect deviations long before breakdowns occur.

Learn more about IoT SensorsLearn more about optimising Maintenance

MaintMaster Audit support Handbook

MaintMaster Maintenance Manual - Update your maintenance today

MaintMaster KPI Manual - Unlock the power of measuring maintenance

Analysis & Reporting frequently asked questions

- What does visualising maintenance insights mean for my organisation?

- When using maintenance software that have Analysing and reporting feature with maintenance data helps to understand operations and identify key areas for improvement, reducing downtime and increasing efficiency.

- How can visualising maintenance insights help improve productivity and save costs?

- By visualising resource allocation, work orders, assets and more, and even combining data sources for new insights, it can help identify bottlenecks and inefficiencies to make changes that improve efficiency.

- How can visualising maintenance insights help prevent machine breakdowns?

- Identifying patterns or trends that indicate potential maintenance issues, can help to act before breakdowns or other serious problems occur.

- How can visualising maintenance insights improve safety in my organisation?

- Analysing accident and injury data, will identify potential safety hazards and reduce the risk of accidents and injuries.

- How can visualising maintenance insights help you use resources more efficiently?

- Analysing task data, equipment, downtime and other factors will help allocate resources more effectively and make smart long-term strategic decisions about equipment and operations.

- How can visualise maintenance insights help optimise operations?

- By leveraging the power of data analysis and reporting, it can improve performance on equipment, facilities, and processes and achieve maintenance goals.