A smarter way to digitalise your maintenance

Depending on where you are in your digital journey, you face different challenges. Either you are just starting out and trying to move away from pen and paper, or you are trying to take the next step with a more strategic approach.

With MaintMaster, you don't just get a software provider, you get a partner with in-depth knowledge and experience from the real world of maintenance.

We know your problems

Eliminate the challenges of analog maintenance

INACCURATE MAINTENANCE WORK

Analogue maintenance relies on manual record keeping, which can lead to errors and inaccuracies in the data. This can make tracking maintenance tasks and identifying patterns or trends difficult. For example, if a maintenance technician records that a particular task has been completed, but the task was never actually completed, this could lead to confusion and delays in future maintenance.

Overall, the risk of errors and inaccuracies in manual record-keeping can make it difficult for maintenance departments to effectively track and manage maintenance tasks, which can affect the efficiency and effectiveness of their operations.

ANALOGUE IS INEFFICIENT

Analogue maintenance processes can be inefficient for several reasons.

Firstly, they require maintenance personnel to manually record and track maintenance tasks, which can be time-consuming and labour-intensive. This can lead to maintenance delays as staff spend time manually entering data and updating records.

In addition, these processes can be prone to error because they rely on manual input and often lack the ability to track and record maintenance tasks automatically.

This can result in missed or incomplete tasks, affecting the overall efficiency and effectiveness of maintenance operations.

MAINTENANCE IS NOT VISIBLE

Analogue maintenance processes rely on manual record-keeping and communication methods, making it difficult for maintenance or site managers to get a clear, up-to-date picture of what is happening on the ground.

Without real-time data on the status of maintenance tasks, it can be challenging for managers to identify and address issues in a timely manner. This can lead to delays and potentially even costly downtime if problems are not addressed promptly.

SCALABILITY IS LIMITED

Analogue maintenance processes rely on manual record-keeping and communication methods, making it difficult to scale up as a company grows.

As the number of maintenance tasks increases, manually tracking and recording them all becomes increasingly challenging. This can lead to errors and inconsistencies in the data and tasks, which can make it difficult for maintenance and site managers to scale up.

MaintMaster digitises maintenance operations, optimising asset utilisation, reducing downtime, controlling costs and simplifying maintenance tasks for maintenance personnel.

- 30 Fewer Downtimes

- 80 Reduced Manual Handling

- 50 Fewer Administration Hours

- 60 Increased Productivity

Say Goodbye to analog maintenance headaches

ENHANCED ACCURACY FOR YOUR MAINTENANCE

One of the key benefits of using maintenance management software is enhanced accuracy. By streamlining maintenance processes and reducing the risk of errors, a CMMS can help organizations improve the reliability and integrity of their data, which is critical for decision-making and operations.

This can be particularly beneficial for companies that rely on large amounts of data or have complex maintenance processes. It can help ensure that critical information is accurately tracked and reported.

INCREASE EFFICIENCY AND OEE

One of the key benefits of using a CMMS is that it can help maintenance departments minimise the number of unplanned repairs by providing real-time data on the condition and maintenance needs of equipment, which can help organisations identify and address potential problems before they become significant issues.

By reducing downtime and unplanned repairs, CMMS software can help companies improve their Overall Equipment Effectiveness (OEE) and increase productivity and profitability.

BETTER ASSET MANAGEMENT

Effective asset management is critical to the smooth running of any business.

CMMS software can help organisations track the usage and performance of each asset, which can help organisations optimise their maintenance schedules and extend the life of their equipment.

Providing accurate and up-to-date data about their assets can help organisations make informed decisions about their maintenance processes and ensure their equipment is in good working order.

INCREASED COST SAVINGS

By reducing the number of unplanned repairs and improving the efficiency of maintenance operations, maintenance management software can help organisations save money on maintenance costs. Unplanned repairs can be particularly costly as they often require urgent attention and can disrupt operations.

By using a CMMS to track and manage the maintenance needs of their equipment, companies can identify and address potential issues before they become major problems. This can save a lot of money.

WE HELP YOU DIGITALISE YOUR INDUSTRY

- Process Industry

-

-

We decided to go for MaintMaster because of their tool flexibility, the customer support they provide and how willing MaintMaster is to take on board our input to further improve the quality of their products. Manuel Medina, Engineering Projects Manager, Gränges Americas Inc Read more about Gränges success

-

Did you know that the first customer that joined MaintMaster, was from the process industry? Therefore, we consider us an expert in the field. With over 20 years of experience, we know how hard and challenging it can be to operate in this industry, that’s why we are here to make it easier for you! Check out the industry

-

- Food & Beverage

-

-

With our previous solution, it obviously would cost us a lot of money to change anything. They wanted us to work to their system. Your system will work to whatever we want. It’s so versatile that we can basically make it do anything. Geoff Kynaston-Stear, H&S Manager, Bedgrow Read more about Bedgrows success

-

The Food and Beverages industry have a high standard when it comes to production, with all the documentation that needs to meet the standards. With pen and paper this is an impossible task, but with MaintMaster you can feel comfortable that you have everything you need to be a successful producer. Check out the industry

-

- Automotive

-

-

We have built up a high level of trust for the maintenance department, and, thanks to the continuous dialog with the production, there’s always a relatively high understanding for preventive maintenance. Erik Arnesson, Project Manager, Automotive Components Floby AB Read more about AC Flobys success

-

Working in a stressful environment is a common thing for people in the automotive industry. But does it really have to be like this? The answer is no, and the solution is MaintMaster. Check out the industry

-

- Energy & Engineering

-

-

There are many people in maintenance that have worked with MaintMaster. And as it turned out, MaintMaster was that good that we didn’t need to try anything else. Anders Carlberg, Production Technician, Svensk Plaståtervinning Read more about Svensk Plaståtervinning success

-

Working in a high demanding environment can be a very stressful task, but when you have a maintenance software that can help you plan your day-to-day work, it becomes a lot easier. No more excel files and running around printing papers. Check out the industry

-

- Manufacturing

-

-

Entering the number of the work order directly on the invoice makes it possible to monitor easily the jobs that have been completed, and to match them against our own records. Stefan Svensson, Maintenance Manager, Anzla Orkla House Care Read more about the success at Anzla Orkla House Care

-

When working within the manufacturing industry you are working with raw materials that need to be transformed into finished products that other industries can use in their production, and in some cases even the consumer itself. That’s why the manufacturing industries needs to have a dynamic maintenance system, just like MaintMaster. Check out the industry

-

-

We decided to go for MaintMaster because of their tool flexibility, the customer support they provide and how willing MaintMaster is to take on board our input to further improve the quality of their products. Manuel Medina, Engineering Projects Manager, Gränges Americas Inc Read more about Gränges success

-

Did you know that the first customer that joined MaintMaster, was from the process industry? Therefore, we consider us an expert in the field. With over 20 years of experience, we know how hard and challenging it can be to operate in this industry, that’s why we are here to make it easier for you! Check out the industry

-

With our previous solution, it obviously would cost us a lot of money to change anything. They wanted us to work to their system. Your system will work to whatever we want. It’s so versatile that we can basically make it do anything. Geoff Kynaston-Stear, H&S Manager, Bedgrow Read more about Bedgrows success

-

The Food and Beverages industry have a high standard when it comes to production, with all the documentation that needs to meet the standards. With pen and paper this is an impossible task, but with MaintMaster you can feel comfortable that you have everything you need to be a successful producer. Check out the industry

-

We have built up a high level of trust for the maintenance department, and, thanks to the continuous dialog with the production, there’s always a relatively high understanding for preventive maintenance. Erik Arnesson, Project Manager, Automotive Components Floby AB Read more about AC Flobys success

-

Working in a stressful environment is a common thing for people in the automotive industry. But does it really have to be like this? The answer is no, and the solution is MaintMaster. Check out the industry

-

There are many people in maintenance that have worked with MaintMaster. And as it turned out, MaintMaster was that good that we didn’t need to try anything else. Anders Carlberg, Production Technician, Svensk Plaståtervinning Read more about Svensk Plaståtervinning success

-

Working in a high demanding environment can be a very stressful task, but when you have a maintenance software that can help you plan your day-to-day work, it becomes a lot easier. No more excel files and running around printing papers. Check out the industry

-

Entering the number of the work order directly on the invoice makes it possible to monitor easily the jobs that have been completed, and to match them against our own records. Stefan Svensson, Maintenance Manager, Anzla Orkla House Care Read more about the success at Anzla Orkla House Care

-

When working within the manufacturing industry you are working with raw materials that need to be transformed into finished products that other industries can use in their production, and in some cases even the consumer itself. That’s why the manufacturing industries needs to have a dynamic maintenance system, just like MaintMaster. Check out the industry

Learn the basic of a CMMS

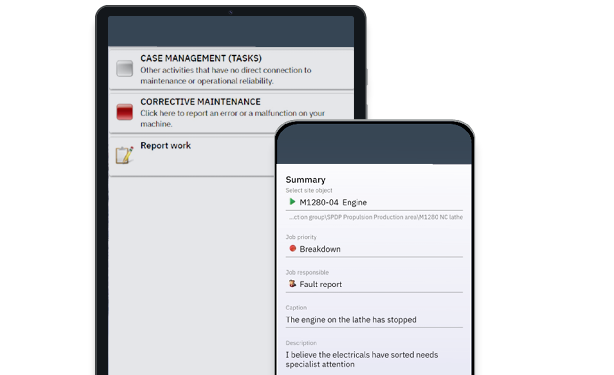

Have you ever wondered how large organisations manage to keep all their equipment and assets in good working condition? Well, the answer is a CMMS software! A Computerised Maintenance Management System is a powerful tool that can help you keep track of all your maintenance activities. By using a CMMS, you can easily schedule tasks, track maintenance history, and even analyse data to make better decisions. It's like having a personal assistant for your maintenance department!

Digitalise Maintenance

frequently asked questions

- Why do I need MaintMaster for my maintenance digitalisation?

- With MaintMaster, you don't just get a software provider, but a partner with solid knowledge and experience from real maintenance work.

- What are the challenges of analogue maintenance?

- Inaccurate manual records, inefficiency, lack of visibility and limited scalability are some of the challenges of manual maintenance processes.

- How does MaintMaster help with accuracy?

- MaintMaster streamlines maintenance processes, reduces the risk of errors and improves the reliability and integrity of maintenance data for better decision making.

- What are the benefits of MaintMaster in terms of efficiency and OEE?

- MaintMaster helps minimise unplanned repairs and provides real-time data on maintenance needs, leading to increased OEE, productivity and profitability.

- What cost savings can I expect with MaintMaster?

- By reducing unplanned repairs and improving maintenance efficiency, MaintMaster helps companies save money on maintenance costs.