- Why MaintMaster

- Maintenance excellence for industries

The road to maintenance excellence

Maintenance Excellence — Let´s get started

You're on the right path.

Do you ever experience that persistent feeling of being stuck in a rut? It's your brain's way of urging you to make a change. And what better way to bring about a transformation than by striving for maintenance excellence? Not only will it enhance your job satisfaction, but it will also lead to greater productivity. So why wait any longer?

Embark on the journey towards excellence today!

Start the transformation of your department

With our expertise spanning over two decades, we have successfully identified the crucial transformations necessary for organisations to achieve maintenance excellence. One significant aspect we often observe is a cultural shift in perceiving maintenance as an essential practice.

To foster a shared vision and mission within your maintenance organisation, effective communication throughout the entire company is vital.

The key transformations that every organisation must undergo include:

- Recognizing the potential for positive change.

- Instilling a profound shift in attitude within the organisation.

- Altering the way people approach their work.

- Ensuring steadfast adherence to these changes.

Standards are good

Continuous improvement requires the right tools and structure. That is why MaintMaster has implemented EU standardisation (EN 13306:2017) within the software itself, so you can be sure that you are meeting the requirements of your industry.

Want to know more? Then, take a look at the maintenance manual.

Maintmaster's maintenance software is designed to optimise asset performance, minimise disruption, control costs, streamline maintenance processes and simplify the work of technicans, leading to maintenance excellence.

- 30 Fewer Downtimes

- 60 Increased Productivity

- 50 Fewer Administration Hours

- 25 Reduced Stock Levels

The four phases to reach maintenance excellence

1. Create a purpose for change

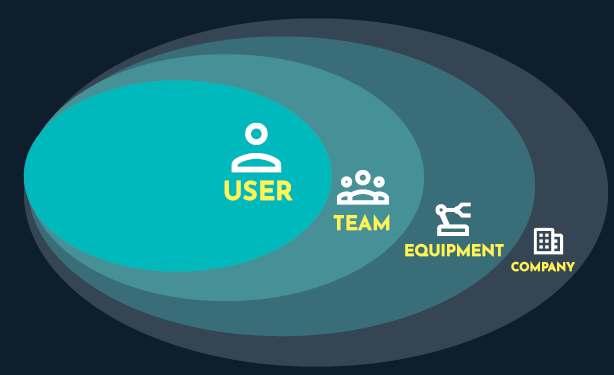

When working with a new tool, you need to establish a clear purpose for the rest of the team and the organisation as to why this implementation is taking place. Most importantly, you need to create an understanding of what they are supposed to be doing in the software itself and what larger purpose it is solving.

It is vital that everyone understands the overall vision and mission of maintenance, what they are supposed to do and how they are supposed to do it. Therefore, creating an order of how things should be done within the software itself is key to successful implementation.

2. Measure your success

A clear vision and mission help an organisation improve transparency and understanding between teams and managers. It helps break down barriers between departments and individuals and encourages people to take ownership of their work.

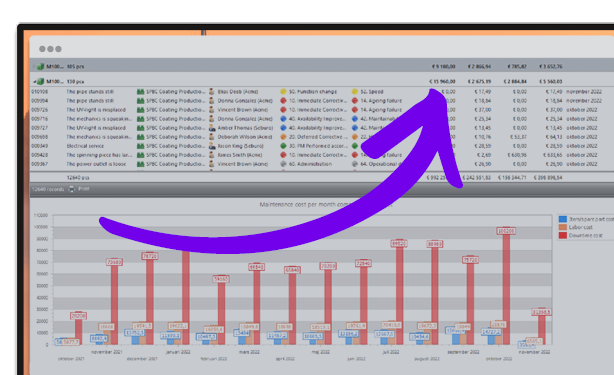

To further improve control and understanding of costs, problems and attitudes, a company needs to take a proactive approach, including classifying equipment and spare parts, using KPI and root cause analysis tools, and working with individual competence to conduct daily monitoring, inspection and cleaning. It's important to remember to use the information to make positive changes and to be aware of the culture you want to create.

3. Start improving

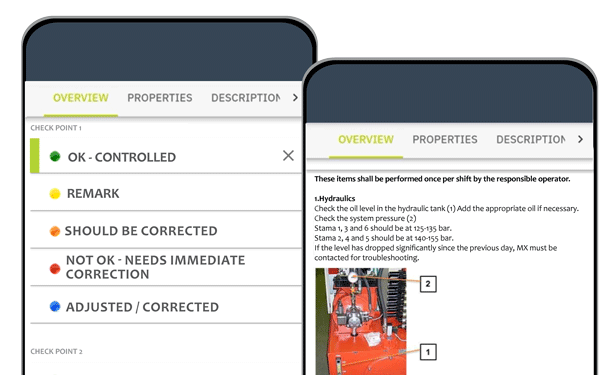

The improvement phase focuses on maintaining a sustainable culture and standardising work processes to ensure efficiency. In this phase, it is important that the maintenance department clearly understands how tasks should be performed and documented and that work orders are easily accessible.

Overall, the goal of the improvement phase is to create a strong foundation for long-term success by establishing sustainable processes and a mindset of continuous improvement.

4. Continuous improvements

Regularly reviewing and updating working methods will help to improve individual performance and foster a culture of independence and creativity within the team.

By encouraging team members to think outside the box and come up with their own ideas for improvement, you can tap into their unique skills and perspectives. This collaborative approach is often more effective than working in silos, as it allows for the sharing of ideas and the opportunity to identify new solutions that might otherwise be overlooked.

Once this mindset is established, you may discover 'hidden gems', innovative ideas or processes that can significantly improve operational safety in production. It's important to remember that creating a culture of continuous improvement requires ongoing effort and commitment.

WE HELP YOU EXCEL IN YOUR INDUSTRY

- Process Industry

-

-

We decided to go for MaintMaster because of their tool flexibility, the customer support they provide and how willing MaintMaster is to take on board our input to further improve the quality of their products. Manuel Medina, Engineering Projects Manager, Gränges Americas Inc Read more about Gränges success

-

Did you know that the first customer that joined MaintMaster, was from the process industry? Therefore, we consider us an expert in the field. With over 20 years of experience, we know how hard and challenging it can be to operate in this industry, that’s why we are here to make it easier for you! Check out the industry

-

- Food & Beverage

-

-

With our previous solution, it obviously would cost us a lot of money to change anything. They wanted us to work to their system. Your system will work to whatever we want. It’s so versatile that we can basically make it do anything. Geoff Kynaston-Stear, H&S Manager, Bedgrow Read more about Bedgrows success

-

The Food and Beverages industry have a high standard when it comes to production, with all the documentation that needs to meet the standards. With pen and paper this is an impossible task, but with MaintMaster you can feel comfortable that you have everything you need to be a successful producer. Check out the industry

-

- Automotive

-

-

We have built up a high level of trust for the maintenance department, and, thanks to the continuous dialog with the production, there’s always a relatively high understanding for preventive maintenance. Erik Arnesson, Project Manager, Automotive Components Floby AB Read more about AC Flobys success

-

Working in a stressful environment is a common thing for people in the automotive industry. But does it really have to be like this? The answer is no, and the solution is MaintMaster. Check out the industry

-

- Energy & Engineering

-

-

There are many people in maintenance that have worked with MaintMaster. And as it turned out, MaintMaster was that good that we didn’t need to try anything else. Anders Carlberg, Production Technician, Svensk Plaståtervinning Read more about Svensk Plaståtervinning success

-

Working in a high demanding environment can be a very stressful task, but when you have a maintenance software that can help you plan your day-to-day work, it becomes a lot easier. No more excel files and running around printing papers. Check out the industry

-

- Manufacturing

-

-

Entering the number of the work order directly on the invoice makes it possible to monitor easily the jobs that have been completed, and to match them against our own records. Stefan Svensson, Maintenance Manager, Anzla Orkla House Care Read more about the success at Anzla Orkla House Care

-

When working within the manufacturing industry you are working with raw materials that need to be transformed into finished products that other industries can use in their production, and in some cases even the consumer itself. That’s why the manufacturing industries needs to have a dynamic maintenance system, just like MaintMaster. Check out the industry

-

-

We decided to go for MaintMaster because of their tool flexibility, the customer support they provide and how willing MaintMaster is to take on board our input to further improve the quality of their products. Manuel Medina, Engineering Projects Manager, Gränges Americas Inc Read more about Gränges success

-

Did you know that the first customer that joined MaintMaster, was from the process industry? Therefore, we consider us an expert in the field. With over 20 years of experience, we know how hard and challenging it can be to operate in this industry, that’s why we are here to make it easier for you! Check out the industry

-

With our previous solution, it obviously would cost us a lot of money to change anything. They wanted us to work to their system. Your system will work to whatever we want. It’s so versatile that we can basically make it do anything. Geoff Kynaston-Stear, H&S Manager, Bedgrow Read more about Bedgrows success

-

The Food and Beverages industry have a high standard when it comes to production, with all the documentation that needs to meet the standards. With pen and paper this is an impossible task, but with MaintMaster you can feel comfortable that you have everything you need to be a successful producer. Check out the industry

-

We have built up a high level of trust for the maintenance department, and, thanks to the continuous dialog with the production, there’s always a relatively high understanding for preventive maintenance. Erik Arnesson, Project Manager, Automotive Components Floby AB Read more about AC Flobys success

-

Working in a stressful environment is a common thing for people in the automotive industry. But does it really have to be like this? The answer is no, and the solution is MaintMaster. Check out the industry

-

There are many people in maintenance that have worked with MaintMaster. And as it turned out, MaintMaster was that good that we didn’t need to try anything else. Anders Carlberg, Production Technician, Svensk Plaståtervinning Read more about Svensk Plaståtervinning success

-

Working in a high demanding environment can be a very stressful task, but when you have a maintenance software that can help you plan your day-to-day work, it becomes a lot easier. No more excel files and running around printing papers. Check out the industry

-

Entering the number of the work order directly on the invoice makes it possible to monitor easily the jobs that have been completed, and to match them against our own records. Stefan Svensson, Maintenance Manager, Anzla Orkla House Care Read more about the success at Anzla Orkla House Care

-

When working within the manufacturing industry you are working with raw materials that need to be transformed into finished products that other industries can use in their production, and in some cases even the consumer itself. That’s why the manufacturing industries needs to have a dynamic maintenance system, just like MaintMaster. Check out the industry

WANT TO KNOW MORE ABOUT OUR FEATURES?

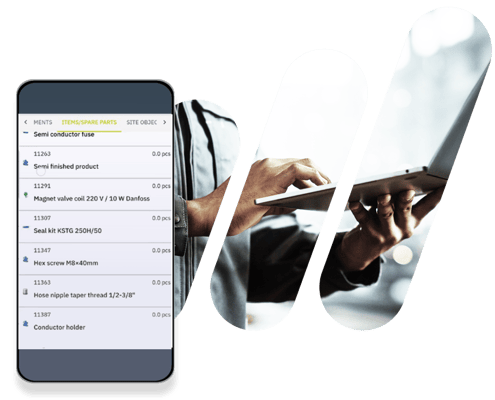

Our platform is user-friendly and optimized for speed, delivering quick access to the most in-demand features and information tailored to your unique requirements.

Read more about Mobile maintenance

Unleash the power of proactive maintenance with MaintMaster IoT sensors. Experience a new level of reliability and efficiency by detecting potential problems before they become major breakdowns.

Read more about IoT sensors

Enter the era of intelligent maintenance with data at the forefront. By harnessing the power of visualised maintenance data and insights, we unlock opportunities to optimise performance.

Read more about analysis & reportingFor your role

- Maintenance Manager

-

-

It's time to get rid of pen and paper and put yourself and your Maintenance Team in the spotlight and get the recognition they deserve. Own and control all your maintenance processes and ressources. Be able to minimize downtimes, have a clean asset history, manage your staff and more... Make analyses in a way you thought it was not possible and show the results to your stakeholders. No more questions about what you and your technicans doing all day. It was never easier to become the star of the company. Learn more about the benefits for a Maintenance Manager

-

- Production Manager

-

-

Production and Maintenance can have a great relationship! With a maintenance department that is able to do, report, and communicate its work using MaintMaster, the production is more efficient and experiences less unplanned downtimes. And the other way arround it´s the same. By using MaintMaster to report on machine failures, Production Departments can increase productivity while decreasing costs. A Win-Win for the whole company. Learn more about the benefits for a Production Manager

-

- Site Manager

-

-

With the right maintenance software used by the maintenance department and production, your plant will run like an assembly line that never stops. Both departments will be able to plan, track and measure their work in one central platform. They become performance monsters. Site Managers no longer need to fret about unplanned downtime and always keep track of costs thanks to MaintMaster's reporting function. It doesn't get any better than that. Learn more about the benefits for a Site Manager

-

- IT Manager

-

-

MaintMaster is a cloud-based software that comes to you as Software as a Service. The software can be rolled out in your company without much effort from the IT department. We at MaintMaster ensure its runnability and data availability. Its architecture makes it easy to integrate into the existing system landscape. No complicated client installations are necessary and through our partners such as Microsoft, your data is always secure. In the end, less stress for your IT department. Learn more about the benefits for a IT Manager

-

- Finance Manager

-

-

With the right maintenance software used by the maintenance department and production, your plant will run like an assembly line that never stops. Both departments will be able to plan, track and measure their work and keep track of their budget. They become performance heroes. A a result of that performace boost will decrease costs and make a hugh impact on the ROI. Learn more about the benefits for a Finance Manager

-

-

It's time to get rid of pen and paper and put yourself and your Maintenance Team in the spotlight and get the recognition they deserve. Own and control all your maintenance processes and ressources. Be able to minimize downtimes, have a clean asset history, manage your staff and more... Make analyses in a way you thought it was not possible and show the results to your stakeholders. No more questions about what you and your technicans doing all day. It was never easier to become the star of the company. Learn more about the benefits for a Maintenance Manager

-

Production and Maintenance can have a great relationship! With a maintenance department that is able to do, report, and communicate its work using MaintMaster, the production is more efficient and experiences less unplanned downtimes. And the other way arround it´s the same. By using MaintMaster to report on machine failures, Production Departments can increase productivity while decreasing costs. A Win-Win for the whole company. Learn more about the benefits for a Production Manager

-

With the right maintenance software used by the maintenance department and production, your plant will run like an assembly line that never stops. Both departments will be able to plan, track and measure their work in one central platform. They become performance monsters. Site Managers no longer need to fret about unplanned downtime and always keep track of costs thanks to MaintMaster's reporting function. It doesn't get any better than that. Learn more about the benefits for a Site Manager

-

MaintMaster is a cloud-based software that comes to you as Software as a Service. The software can be rolled out in your company without much effort from the IT department. We at MaintMaster ensure its runnability and data availability. Its architecture makes it easy to integrate into the existing system landscape. No complicated client installations are necessary and through our partners such as Microsoft, your data is always secure. In the end, less stress for your IT department. Learn more about the benefits for a IT Manager

-

With the right maintenance software used by the maintenance department and production, your plant will run like an assembly line that never stops. Both departments will be able to plan, track and measure their work and keep track of their budget. They become performance heroes. A a result of that performace boost will decrease costs and make a hugh impact on the ROI. Learn more about the benefits for a Finance Manager

LEARN MORE ABOUT MAINTENANCE EXCELLENCE

Need to learn the basics of a CMMS?

If you're new to maintenance management, you may wonder how to start with CMMS software. A CMMS software, short for Computerised Maintenance Management System, is a tool that can help you manage your maintenance activities more efficiently. With a CMMS, you can easily plan and schedule maintenance tasks, track work orders, and even create reports to analyse your maintenance data. Using a CMMS, you can simplify your maintenance operations and ensure everything runs smoothly.

Maintenance Excellence

frequently asked questions

- Why should organisations strive for maintenance excellence?

- The current way of working is not sustainable and the opportunity to change things for the better should always be seized.

- What key changes do organisations need to make to achieve maintenance excellence?

-

- Recognising that change is possible

- Changing attitudes within the organisation

- Changing work behaviour

- Sticking with the changes

- How is the EU standardisation used by MaintMaster?

- MaintMaster implements the EU standardisation (EN 13306:2017) within the software to ensure compliance with industry requirements.

- What are the four phases to reach maintenance excellence?

-

- Creating order to be able to change

- Measuring success

- Starting improvement

- Continuous improvement