OEE improvement <6months

Win the shift with visual performance data

Keep your teams aligned, reduce downtime, and stay on target with real-time visual data from Maintmaster OEE. No delays. No debates. Just facts that drive action.

Why teams use Maintmaster OEE

Make every shift count

Turn scattered information into clear, shared insights everyone can act on.

Spot issues instantly

See exactly when and why performance drops. And fix it in real time.

Build a CI culture

Align teams around live facts that drive real continuous improvement, not delayed reports or assumptions.

From guesswork to clarity

Before

Teams lose time when data stays hidden

Many plants still run without true visibility. Operators work blind, managers rely on yesterday’s reports, and small stoppages add up to hours of lost output.

With no single version of the truth, meetings turn into debates instead of decisions.

Action

From guessing to knowing

Maintmaster OEE gives everyone — operators, engineers, and managers — a shared view of real-time performance.

Teams see what’s happening as it happens, respond faster, and make confident, data-driven decisions. Instead of chasing yesterday’s losses, they act on live facts, keeping every shift productive and connected.

Result

Visible data. Engaged teams. Measurable gains.

With Maintmaster OEE, surprises disappear. Teams share the same data, act sooner, and prevent hidden losses from snowballing.

The result? Higher OEE, fewer stoppages, and engaged teams working towards the same goals — shift after shift.

Turn live data into

team action

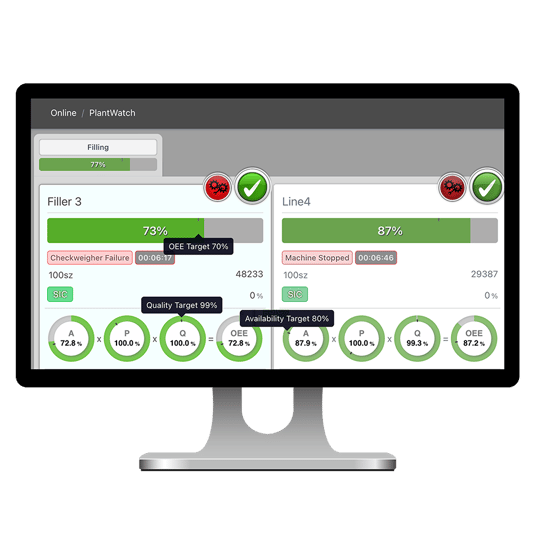

See the whole factory — live

You can’t fix what you can’t see. Maintmaster OEE visualises your entire production in real time.

Lines are colour-coded by status — green, amber, or red — giving instant clarity across shifts and sites.

Click on any line for detail. Create tailored dashboards to match your teams reporting needs.

Know exactly why lines stop

When a line stops, it turns red. The reason is logged instantly. Operators can reassign root causes, split overlapping issues, and leave notes — all fully traceable.

Short stops and micro-delays are captured too, giving complete accuracy over where time really goes.

Lock in targets and react fast

Set clear OEE targets for speed, quality, and availability.

Short Interval Control charts help supervisors step in mid-shift, while visual alerts highlight performance drops instantly.

Everyone sees the same data — operators, maintenance, and management — keeping the team aligned and proactive.

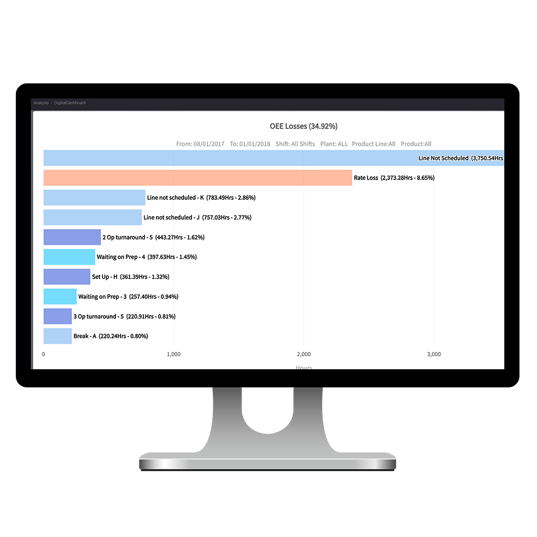

Go beyond fixing. Start preventing

Use Pareto charts to reveal top losses at a glance.

Drill into any bar to see when and how issues occurred, and track production by shift, product, or line.

Click and filter for detailed views by time, cost, or shift — no exports, no analysts needed.

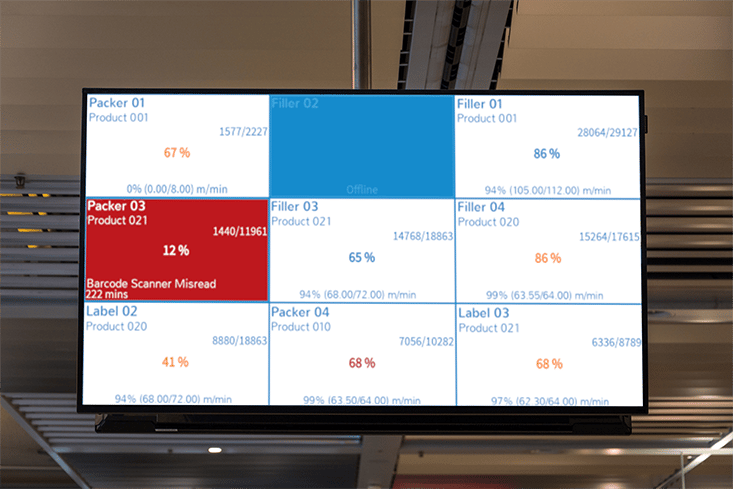

Keep every team in sync

Large-screen dashboards create one version of the truth.

Engineers, operators, and supervisors see the same live data, use the same codes, and share shift notes directly in the system — ensuring nothing gets lost between teams.

Proven results — Data-driven gains in OEE and uptime

Reduction in unplanned downtime

Reduced changeover variance

Reduction in idling and short stops

"We didn’t want a system that just tracked OEE. We wanted something that helped us act on issues in real time."

- Müller Milk & Ingredients

"Before, we’d classify good days or bad days based on how people felt a shift went."

- Chairmans Foods

Before and after

Maintmaster OEE

The old way

Disconnected, delayed, unclear

- No live visibility

- Missed micro-stops and hidden losses

- Data silos and manual reports

- Disputes over whose numbers are right

The new way

Visible, aligned, engaged

- Live dashboards for every team

- Real-time loss tracking and alerts

- One version of the truth

- Continuous improvement culture

Take control of your production with Maintmaster OEE

Get your factory talking in real time

Unite your teams around a shared, real-time view of performance. With MaintMaster OEE, you eliminate guesswork, reduce downtime, and keep every shift on track — with live data that drives faster, better decisions across the plant.

See other OEE use cases

Preventing Unplanned Downtime

Spot downtime as it happens, uncover root causes fast, and prevent disruptions before they hit your targets.

Performance Benchmarking

Create one version of the truth across all sites, reveal hidden losses, and drive measurable improvement.

Production Monitoring

Spot downtime as it happens, uncover root causes fast, and prevent disruptions before they hit your targets.

Supporting CI Projects & Teams

One source of truth for every team, turning data debates into measurable results on every shift.

Improving Changeover Efficiency

Make every changeover repeatable, efficient, and a driver of continuous improvement.

CMMS & AI

Turn maintenance data into clear, actionable insights. Helping teams spot patterns, solve root causes, and improve reliability.

Learn moreFrequently asked questions

- How quickly can we deploy live dashboards?

-

Most plants are live within 3–4 weeks. Maintmaster connects to existing PLCs and signals — no major hardware changes required.

- Will operators actually use visual dashboards?

- Yes. Clear, colour-coded KPIs make performance easy to understand at a glance.

- Do we need new hardware for big screens?

- Usually not. Maintmaster runs via browser-based interfaces — any PC or thin client can display live dashboards.

- Can we customise dashboards for each area?

- Absolutely. Tailor screens by line, team, or role to keep information focused and relevant.

- What results can we expect?

-

Customers report OEE gains of 10–20%, downtime reductions of up to 68%, and improved team engagement.