Downtime reduction

Master maintenance control with real-time insights

With Maintmaster, maintenance teams turn data into insights to prevent downtime, fix issues early, and move from reactive to proactive maintenance.

Why teams use Maintmaster CMMS

Detect problems

before they escalate

Stay ahead of unplanned downtime with automated alerts and live data.

Turn maintenance data

into action

Analyse trends, spot bottlenecks, and plan smarter interventions.

Drive continuous

improvement

Track KPIs, benchmark performance, and make data-driven decisions.

Turn every alert into action

Before

Without reliable data, you can’t stay ahead of problems

Many maintenance teams lack accurate, comprehensive asset data. Without it, identifying root causes or optimising preventive maintenance becomes guesswork.

This leads to unplanned downtime, reactive work, poor reporting, and missed improvement opportunities — with added pressure to meet audit and compliance requirements.

Action

Identify issues fast. Take action. Improve continuously.

Maintmaster CMMS empowers maintenance teams with real-time insights and structured data. Built with decades of maintenance experience, it connects people, machines, and performance — helping teams move from reactive to proactive maintenance and achieve measurable improvements.

Result

Clear insights. Better decisions. Higher uptime.

With Maintmaster, teams gain visibility into every maintenance event. Issues are detected earlier, downtime is reduced, and continuous improvement becomes part of daily operations. Maintenance finally works with data — not against it.

Powerful tools for

smarter, faster

maintenance decisions

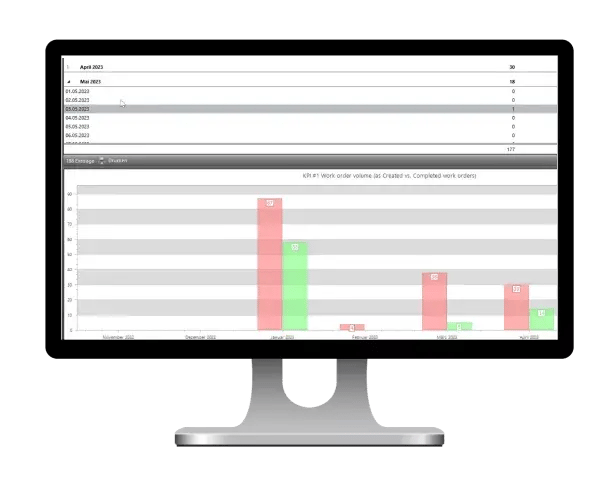

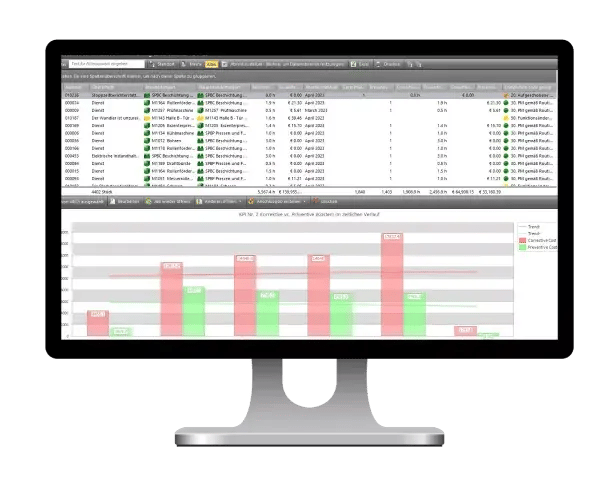

See the whole picture in one view

Gain full visibility with dashboards and reports showing trends, performance, and maintenance effectiveness — enabling targeted actions and smarter planning.

Measure what matters most

Track MTBF, MTTR, downtime, and maintenance costs in real time. Identify areas for improvement and allocate resources based on data — not assumptions.

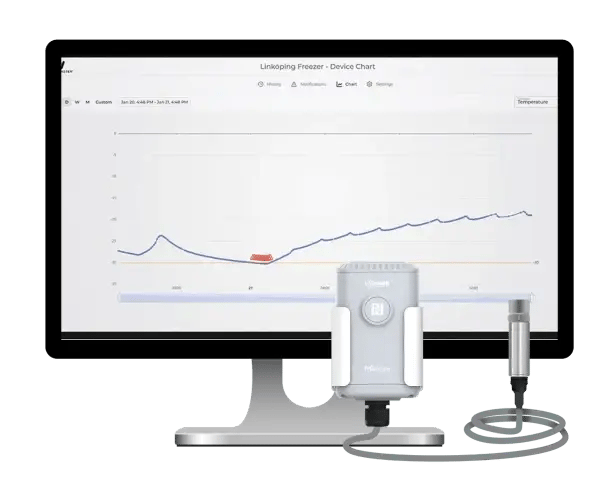

Get alerts before failures happen

Integrate sensors and machine data to trigger alerts before breakdowns occur. Support condition-based and predictive maintenance with confidence.

Proven results — Turning insights into uptime

Visibility of compliance metrics

Increaced productivity

Fewer administration hours

"Before Maintmaster, we used Microsoft Excel to keep track of our maintenance. The big difference today is the history log in MaintMaster. We use it a lot to check how we solved issues that have occurred before, and this has reduced downtime and our MTTR."

- Artur Pawlak, Maintenance Manager, Starsprings Pozna

Before and after

Maintmaster CMMS

The old way

Reactive, blind, inefficient

- Unplanned downtime

- Manual data collection

- Slow root cause identification

- Firefighting instead of planning

The new way

Smart, proactive, data-driven

- Automated alerts and real-time monitoring

- Structured data and reports

- Faster problem-solving

- Continuous improvement culture

Turn data into maintenance insights with Maintmaster CMMS

From reactive to proactive performance

Maintmaster CMMS helps your maintenance team make smarter decisions based on real operational data. Spot issues before they cause downtime, optimise your maintenance activities, and ensure long-term reliability — all while keeping costs under control.

See other CMMS use cases

Production & Maintenance Allignment

Boost uptime and efficiency with seamless alignment between maintenance and production.

Audits & Compliance

Digitise maintenance, ensure compliance, and stay audit-ready without slowing production.

Operator Maintenance

structure, scale, and optimise operator maintenance to boost efficiency and maximise plant availability.

IoT Sensors

Monitor equipment conditions in real time with pre-configured gateways and sensors that integrate seamlessly with your CMMS. Simple to set up and ready to use.

CMMS & AI

Turn maintenance data into clear, actionable insights. Helping teams spot patterns, solve root causes, and improve reliability.

Learn moreFrequently asked questions

- What kind of data can Maintmaster analyse?

-

Any maintenance-related data: downtime, performance, cost, failures, and trends.

- How does Maintmaster help prevent breakdowns?

- IoT alerts and historical analysis detect issues early, supporting predictive maintenance.

- How does Maintmaster support root cause analysis?

- Structured RCA tools and completion codes help identify and eliminate recurring problems.

- How does Maintmaster support audit compliance?

- All activities are traceable, with documentation ready for ISO, IATF, or internal audits.

- What does “visualisation of insights” mean?

-

Dashboards make it easy to understand performance, spot bottlenecks, and act quickly.