OEE improvement <6months

Turn performance data into progress

With Maintmaster OEE, benchmark performance across shifts, lines, and sites—giving everyone a shared, data-driven view of the truth.

Why teams use Maintmaster OEE

Compare performance with confidence

See every line, shift, and site through the same lens with consistent OEE calculations.

Find hidden gaps before they cost you

Reveal underperforming lines, inefficient changeovers, or recurring losses in minutes.

Build a culture of continuous progress

Replace debates with data, align teams, and focus improvement where it matters most.

From data debates to fact-based decisions

Before

Same lines, different numbers

When every line or site measures performance differently, true benchmarking becomes impossible.

Teams spend more time debating data than improving it, and leaders struggle to see where investment is most needed.

Without shared definitions or consistent OEE calculations, improvement efforts remain fragmented and progress uncertain.

Action

Create one version of the truth

Maintmaster OEE standardises how performance is measured and compared. Shared loss codes, consistent definitions, and identical OEE formulas ensure every site speaks the same language.

From live dashboards to historical reports, teams see accurate, comparable data — unlocking true performance benchmarking across shifts, products, or plants.

Result

Visibility that drives improvement

With benchmarking in place, manufacturers turn variation into opportunity.

Teams discover why one line thrives while another struggles, share best practices, and direct improvements where they have the greatest impact — without new equipment or extra cost.

Benchmark with confidence.

One standard. One system.

Real results

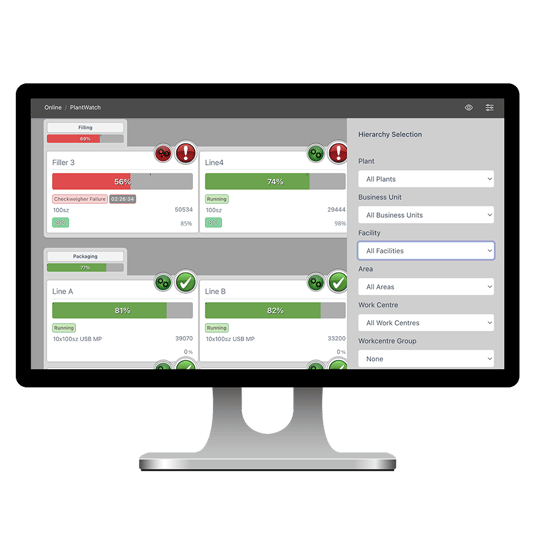

Standardise performance across every site

Establish consistent OEE calculations and loss categories used by every team.

Apply automatically across all plants, ensuring accurate, comparable results.

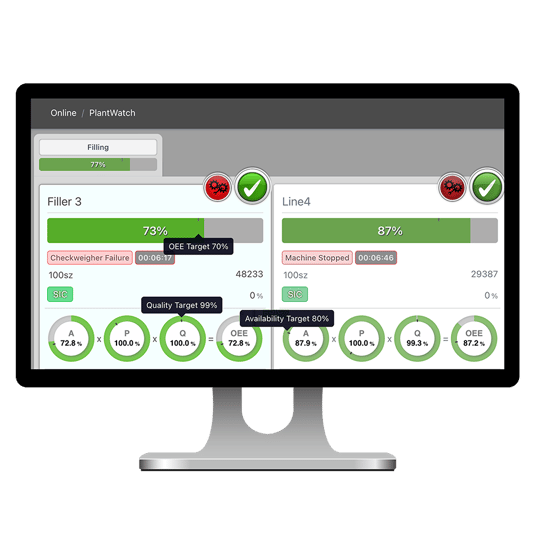

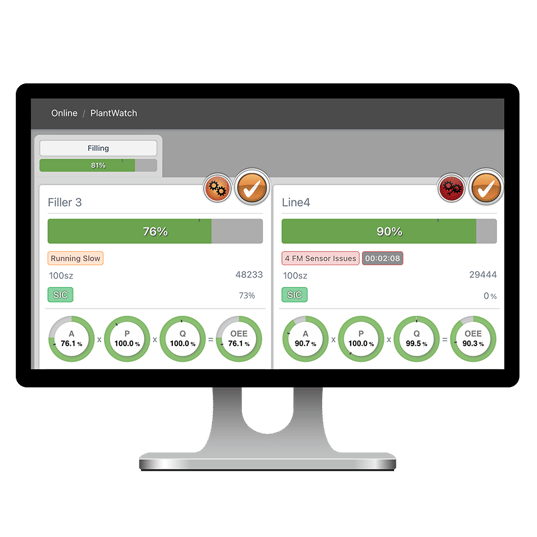

See performance at a glance

View live OEE for every line and site in one screen.

Colour-coded indicators highlight which lines are running well — and which need attention.

Filter instantly by plant, product, or shift for quick analysis.

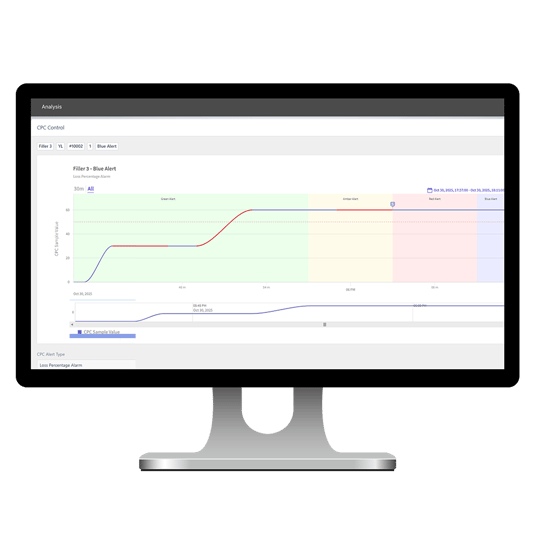

Find the story behind the numbers

Every downtime reason is logged with consistent codes.

Micro-stops, changeover times, and recurring faults become visible patterns that reveal hidden inefficiencies.

Turn hidden losses into capacity

Compare performance by line, shift, or SKU.

Use Pareto charts to see which losses cost the most time and target improvements that deliver real gains.

Protect improvements automatically

Set targets for OEE or loss categories and receive instant notifications if values drift below threshold.

Teams act before problems grow, keeping performance gains locked in.

Proven results — Data-driven gains in OEE and uptime

Reduction in unplanned downtime

Reduced changeover variance

Reduction in idling and short stops

"The ability to compare the three plants is huge. Before, it was all anecdotal… now we can actually say where we’re at and where the problems are."

- Eric Steer, VP of Operations, Chairmans Foods

"Benchmarking is one of the biggest benefits. You’re not just tracking OEE; you’re comparing performance of the same product across different lines — and that tells you where to look."

- Shabaz Mahmood, Manufacturing & Engineering Manager, Science in Sport

Before and after

Maintmaster OEE

The old way

Local data, global confusion

- Inconsistent OEE calculations

- Different loss definitions across sites

- Endless debates over data accuracy

- Wasted time aligning reports

The new way

Shared facts, shared progress

- Standardised data across all plants

- Real-time comparison of lines and shifts

- Clear investment priorities

- Faster, more confident decisions

Take control of your production with Maintmaster OEE

Get clear on performance. Know where to focus

MaintMaster OEE gives you a consistent, real-time view of performance across every line. Benchmark with confidence, identify gaps faster, and act where it counts.

See other OEE use cases

Preventing Unplanned Downtime

Spot downtime as it happens, uncover root causes fast, and prevent disruptions before they hit your targets.

Production Monitoring

Spot downtime as it happens, uncover root causes fast, and prevent disruptions before they hit your targets.

Supporting CI Projects & Teams

One source of truth for every team, turning data debates into measurable results on every shift.

Improving Changeover Efficiency

Make every changeover repeatable, efficient, and a driver of continuous improvement.

Teams & Visual Performance Data

Clear, real-time insights that keep every shift aligned and prevent small losses from becoming big problems.

OEE & AI

Turn production data into clear, actionable insights. Helping teams spot losses, fix root causes, and boost performance every shift.

Learn moreFrequently asked questions

- How do we ensure all sites measure performance the same way?

-

Maintmaster OEE uses shared rules, loss codes, and OEE formulas — giving every site the same definitions and calculations.

- Can we benchmark specific processes like changeovers or cycles?

- Yes. Filter by downtime reason, product, or line to benchmark specific processes such as CIP, cycle times, or changeovers.

- What if different lines run at different speeds or products?

- Each line or SKU can have its own standard and target, ensuring fair, meaningful comparisons.

- Will benchmarking add work for operators?

- No. Most data is captured automatically, and manual entries use quick drop-downs and touch-friendly screens.

- Do we need a formal CI programme to benefit from benchmarking?

-

Not at all. Benchmarking provides actionable facts for any team, helping prioritise improvements even without a structured CI initiative.