Why automotive companies choose Maintmaster

Because performance starts with visibility.

Use Maintmaster CMMS to control maintenance and compliance, or Maintmaster OEE to track production performance and efficiency. Powerful alone and better together, they give you instant results and one overview of your complete operations. Get control, traceability, and high uptime with Maintmasters two solutions. Start with either system or connect to track every fault, downtime event, and efficiency loss, linking maintenance actions to production performance.

01.

Before

Disconnected and reactive work

Maintenance and production silos happen when equipment failures are logged in one system and performance losses sit in another. Reports take days, audits are stressful, and spare parts run out when teams need them the most.

Scattered data makes it hard to see the real downtime cause and harder to prevent them. Maintenance becomes reactive, teams get frustrated, and production losses become increasingly common.

02.

Action

See everything from one interface

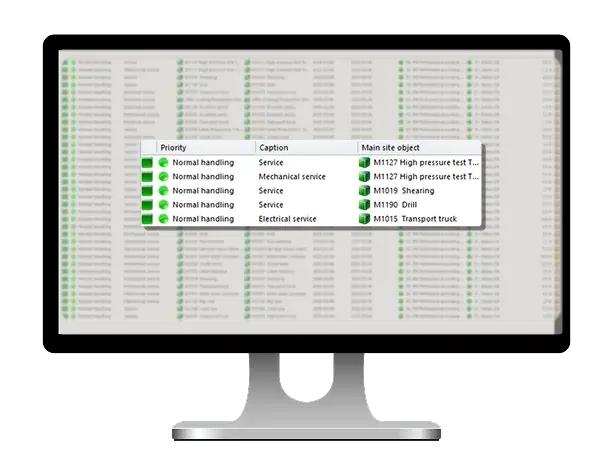

Manage every work order, inspection, and spare part from the CMMS. Get fault reports from the shop floor in seconds, even from a phone, with QR codes and mobile. Make audits effortless with complete traceability meeting IATF and ISO requirements.

See production in real-time with the OEE. Visualise performance, availability, and quality live so teams spot trends, detect losses faster, and act before they escalate. Connect the CMMS and OEE for a closed insight loop.

Identify performance drops with OEE. Fix and prevent it with the CMMS.

That's manufacturing excellence.

03.

Results

See performance gains in real numbers

Automotive manufacturers using Maintmaster CMMS report up to 35% less unplanned while OEE users gain real-time visibility of performance losses and production trends. Predict operations accurately, collaborate across departments. and track every improvement.

When every team operates from the same accurate data, audits become effortless with automatic documentation, and spare-part management proactive. Whether you start with one system or both, Maintmaster helps you move from firefighting to continuous improvement.

- 35 less unplanned downtime with CMMS

- 15 improvement in OEE within the first six months

- 25 faster audit preparation thanks to built-in compliance tracking

- 20 reduction in spare part costs with smarter Stockroom management

Key features and capabilities

Get complete maintenance control

Document every work order and inspection automatically for a complete audit trail built for IATF 16949 and ISO standards. Let your team report issues and close jobs from anywhere with mobile access and QR scanning. With spare-part and stockroom management, you ensure you always have the right part at the right time.

See real-time production performance

Turn live data into action with Maintmaster OEE. Track availability, performance, and quality in real time to see exactly where efficiency is lost and why. Categorise downtime events automatically to see every stop cause. Compare shifts, lines, or plants instantly with unified dashboards for improvement that never stops.

Better together — CMMS + OEE

Use each system alone or connect them for maintenance reliability and production performance that power each other. Trigger work orders in the CMMS automatically when the OEE identifies a problem and see a completed repair reflected in the OEE dashboards. Start with one system and connect when you're ready for full visibility.

The old way

- Separate systems for maintenance and production

- Guesswork about downtime causes

- Stressful audits with missing documentation

- Spare-part shortages or excess stock Reactive maintenance

- Data everywhere, insight nowhere

The new way

- Two specialised tools — CMMS and OEE — that work independently or together

- Real-time root-cause insight

- Automatic traceability built for IATF 16949 and ISO

- Smart stockroom management and automatic reorders

- Preventive, connected operations

- One connected ecosystem for control and performance

Choose CMMS for control.

Choose OEE for visibility.

Combine for excellence.

Frequently asked questions

- How does Maintmaster help people in the automotive industry?

- Maintmaster is a CMMS solution that helps people in the automotive industry to stay on top of innovations and manage their work in a less stressful environment. With European maintenance standards integrated into the system, everything becomes an easier task.

- Why do companies in the automotive industry choose Maintmaster for auditing and documentation?

- Companies choose Maintmaster for auditing and documentation because it provides a tailored solution to their specific reporting needs, has the right key performance indicators, and helps take action before issues arise.

- What is Maintmaster's approach to spare part management and inventory in the automotive industry?

- Maintmaster offers software that acts as a digital home for inventory management and allows sorting, editing and tracking of spare parts. It also helps in setting up the right documentation and spare parts for maintenance work, saving costs and providing a real-time view of inventory status.

- How does Maintmaster support preventive maintenance in the automotive industry?

- Maintmaster helps gather data and insights into equipment performance and aids in preventing breakdowns through better maintenance planning. This leads to less downtime and increased production efficiency.