Why the process industry choose Maintmaster

BECAUSE RELIABILITY STARTS WITH FULL TRACEABILITY.

Use Maintmaster CMMS to manage inspections, audits, and safety procedures, or Maintmaster OEE to monitor production flow and efficiency in real time. Get measurable impact which each system. Connect to align performance, safety, and compliance in one seamless system. Track every action and performance shift, from lubrication checks and work orders to live sensor alerts that reveal issues before they come failures.

01.

Before

Critical stops and paperwork chaos

When systems run 24/7, even small delays ripple across production. Quality drifts, batches are lost, and operators scramble to keep output stable. Paper logs and scattered spreadsheets hide early warning signs that could prevent failures.

Without shared data between maintenance and production, teams chase symptoms instead of causes. Unplanned downtime grows, compliance risks rise, and every restart cuts deeper into margins.

02.

Action

Connect real-time control

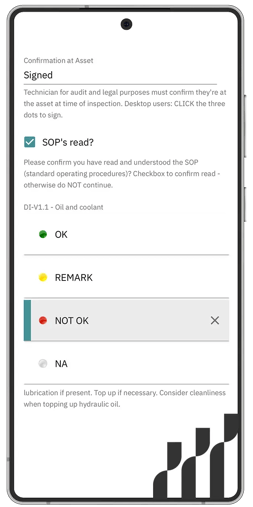

Manage every maintenance task, inspection, and shutdown from the CMMS. Log equipment faults in seconds, straight from the plant floor, with mobile or QR code access. Keep traceability effortless for ISO and safety audits, with every work order stored and searchable.

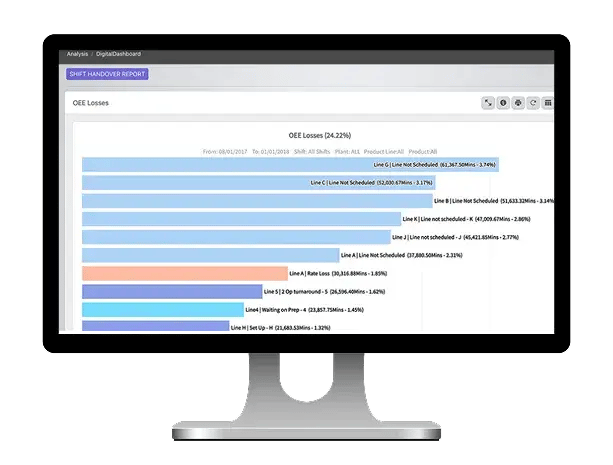

See process performance live with the OEE. Monitor flow, yield, and availability in real time so teams can detect deviations early and correct them before they spread. Connect the CMMS and OEE for a complete feedback loop between production and maintenance.

Spot drift with OEE. Prevent downtime with the CMMS.

That’s process reliability.

03.

Results

Boost uptime together

Process industry companies report reliable uptime, seamless data flows, and total traceability in one place. When every team has access to the same accurate data in Maintmaster, they act faster, waste less, and stay aligned across departments.

Capture every task, inspection, or sensor alert in real-time with instant access to the insights you need to make confident decisions, optimise performance, and stay compliant.

- 35 less unplanned downtime with CMMS

- 15 improvement in OEE within the first six months

- 25 faster audit preparation thanks to built-in compliance tracking

- 20 reduction in spare part costs with smarter Stockroom management

From reactive to excellence

By standardising routines, simplifying workflows, and putting actionable data into the hands of every engineer, MaintMaster has helped Siva move from reactive work toward organised, data-driven engineering excellence — with the flexibility to keep evolving.

Read the full story here

Key features and capabilities

Access anywhere instantly

Scan any machine’s QR code to instantly access its full job history, safety workflows, repair instructions, and documentation — all in one place. Get context to work safely, solve problems faster, and trace every action whether on the shop or in the field.

Trace every action effortlessly

Every step you take is captured automatically, from routine inspections to critical interventions, with full traceability from the plant floor to the control room. Compliance and accountability become effortless, built right into your daily workflows.

Stop breakdowns, scale output

Use OEE to trigger maintenance tasks automatically long before small issues turn into costly breakdowns. With real-time insights into production flow, you can also uncover bottlenecks and pinpoint exactly where efficiency is lost.

Powerful alone, unstoppable together

Maintmaster CMMS and OEE are powerful alone. Connect them when you're ready for a complete system where every production anomaly and maintenance action feeds into the same continuous improvement loop for safe and efficient operations.

The old way

- Critical downtime with no early warnings

- Paper checklists and delayed admin

- Siloed systems with missing data

- Stressful audits and scattered records

The new way

- Real-time IoT alerts and automatic action

- Digital workflows across all lines

- Structured data from best of breed solutions

- Audit proofs generated instantly

Choose CMMS for control.

Choose OEE for visibility.

Combine both for excellence.

frequently asked questions

- What makes Maintmaster a good choice for companies in the process industry?

-

With Maintmaster CMMS, you can standardise procedures, manage audits effortlessly, and ensure safety-critical tasks are always tracked and documented. Meanwhile, Maintmaster OEE gives you real-time visibility into production performance, helping you detect bottlenecks, spot deviations early, and prevent costly breakdowns.

Individually, each system delivers results — but when combined, they create a fully connected loop where machine data triggers maintenance automatically, and completed repairs update performance dashboards in real time. - What are the benefits of using Maintmaster for documentation in the process industry?

- With built-in control, automated logging, and seamless links to both maintenance and production data, MaintMaster helps you reduce risk, eliminate paperwork, and stay ready for audits at any time — without slowing down operations.

- How does Maintmaster help companies in the process industry with audits?

- Maintmaster makes audits faster, easier, and fully reliable by automating the entire traceability process. Every job, safety check, inspection, and signature is logged in real time — creating a digital audit trail without extra paperwork or manual tracking.

- What are the benefits of using Maintmaster for Root Cause Analysis in the process industry?

- Maintmaster simplifies and strengthens Root Cause Analysis by combining complete traceability, structured workflows, and real-time data from both maintenance and production. Every failure, inspection, downtime event, and corrective action is automatically logged, giving you a full and accurate history to analyse — without gaps, guesswork, or missing data.