Why transport and logistics teams choose Maintmaster

BECAUSE RELIABILITY STARTS WITH CONTROL.

Use Maintmaster CMMS to keep every vehicle, asset, and loading system safe and compliant, or Maintmaster OEE to monitor fleet performance and efficiency in real time. Each system delivers clear gains on its own, yet together they provide one connected view of uptime, utilization, and delivery reliability. Start with either system or connect to reveal delays, minimize idle time, and prevent costly breakdowns, turning maintenance insights into smoother logistics and higher fleet availability.

01.

Before

Unplanned delays, scattered information, and no real-time visibility

Drivers report issues late because paper logs and manual routines slow everything down. Warehouse equipment is checked inconsistently, breakdowns happen without warning, and bottlenecks remain hidden until they impact deliveries.

02.

Action

Connect every operator, vehicle, and facility in one digital workflow

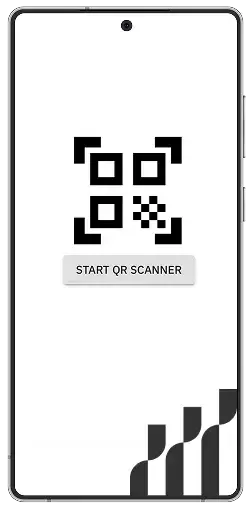

Maintmaster CMMS lets drivers and technicians report faults instantly via QR code or mobile app — without waiting to get back to the office.

Daily checks, inspections, and workflows are standardised and auditable.

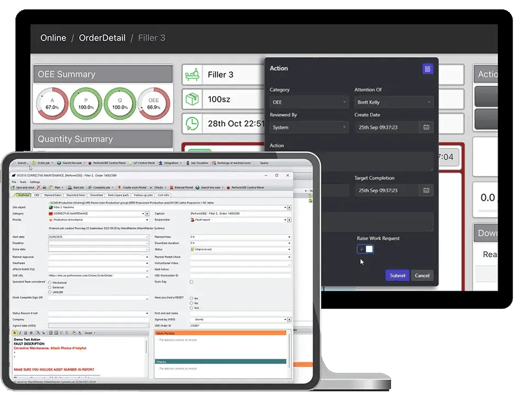

With Maintmaster OEE, you gain real-time data on fleet performance, warehouse equipment efficiency, or process bottlenecks.

03.

Results

Keep breakdowns low, compliance tight, and delivery running on time

Get connected operations and less risk when drivers and operators log issues instantly. Let every vehicle and loading system follow digital safety checks with real-time OEE that trigger maintenance when performance drops in your logistics operations.

- 35 less unplanned downtime with CMMS

- 15 improvement in OEE within the first six months

- 25 faster audit preparation thanks to built-in compliance tracking

- 20 reduction in spare part costs with smarter Stockroom management

Key features and capabilities

Report and resolve faults instantly

Drivers and operators use the Maintmaster app or scan a machine or asset QR code to log issues, add photos, and start a repair job on the spot.

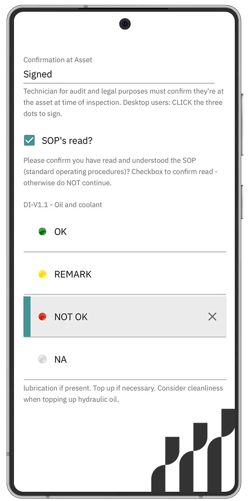

Force safety and inspection routines

Build mandatory checks for vehicles, loading systems, forklifts, dock lifts, and more, all timestamped, stored, and ready for any audit.

Automate with ease

Track availability, idle time, and throughput, automatically triggered and trigger maintenance automatically when performance falls below target.

Better together — CMMS + OEE

Use each system alone or connect them for maintenance reliability and production performance that power each other. Trigger work orders in the CMMS automatically when the OEE identifies a problem and see a completed repair reflected in the OEE dashboards. Start with one system and connect when you're ready for full visibility.

The old way

- Separate systems for maintenance and production

- Guesswork about downtime causes

- Stressful audits with missing documentation

- Spare-part shortages or excess stock Reactive maintenance

- Data everywhere, insight nowhere

The new way

- Two specialised tools — CMMS and OEE — that work independently or together

- Real-time root-cause insight

- Automatic traceability built for IATF 16949 and ISO

- Smart stockroom management and automatic reorders

- Preventive, connected operations

- One connected ecosystem for control and performance

Choose CMMS for control.

Choose OEE for visibility.

Combine for excellence.

frequently asked questions

- How does Maintmaster support the transport and logistics industry?

- Maintmaster offers fault reporting in the field through its cloud-based system and mobile application with QR functionality, daily overview through required fields and real-time view, and quick onboarding for external personnel through tailored working environments.

- Can Maintmaster be used for reporting on the field in the transport and logistics industry?

- Yes, Maintmaster is a cloud-based system and offers a mobile application with QR functionality, allowing for reporting on the field.

- How does Maintmaster provide a daily overview of the transport and logistics industry?

- Maintmaster offers required fields that need to be filled out before handling the equipment and a real-time view of errors submitted through the mobile application, providing a daily overview of equipment.

- How does Maintmaster support the onboarding of external personnel in the transport and logistics industry?

- Maintmaster offers tailored working environments for different users and positions, making the onboarding process quick and efficient with just a short education within the system.