Why Is a Common View Important? 💁

When production doesn’t run smoothly, it can be difficult to pinpoint the cause. Without a shared understanding of the production process, identifying and resolving issues becomes challenging.

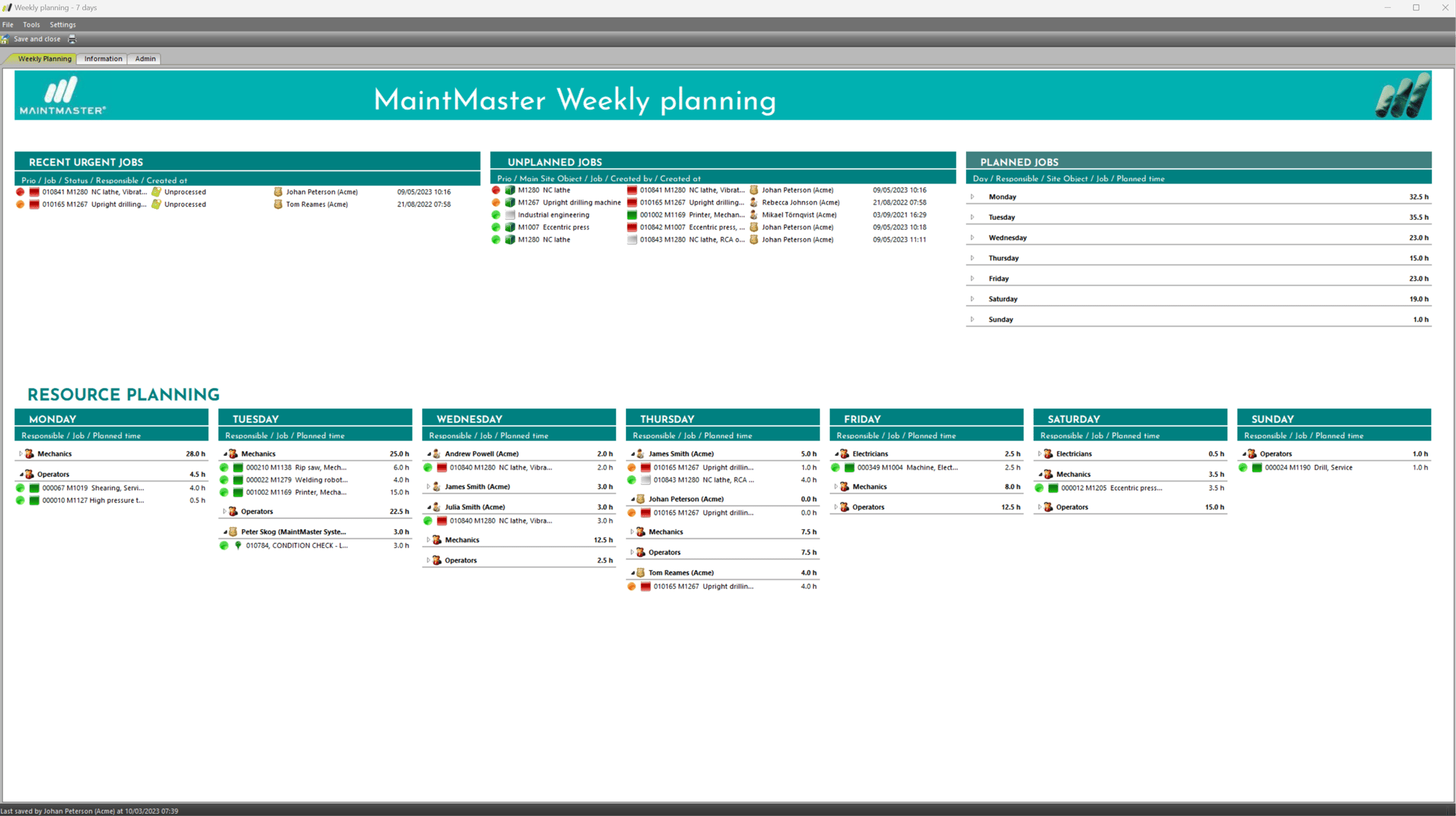

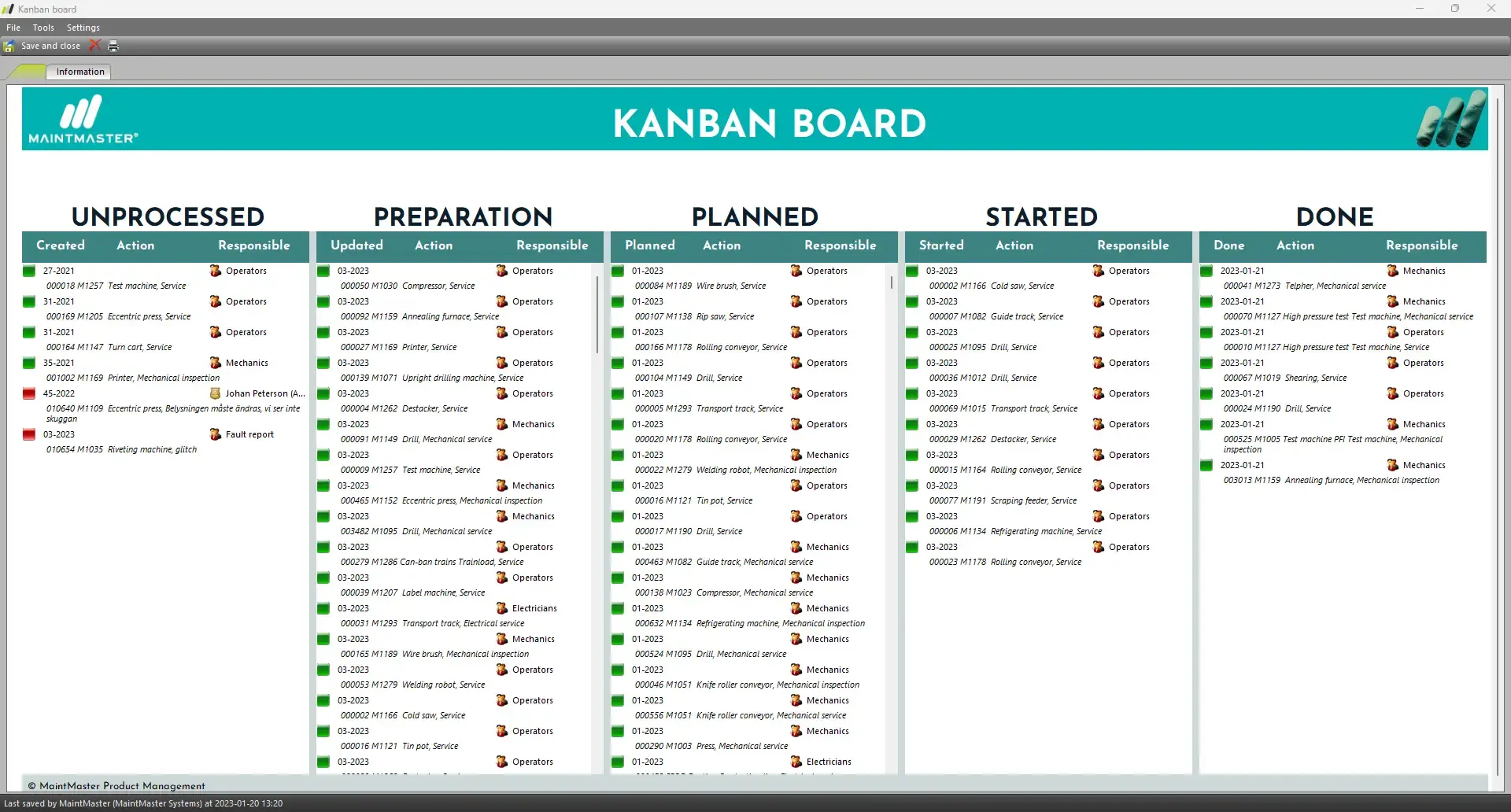

With MaintMaster, you can tackle this issue in multiple ways. Our visualisation tools help create a unified view for both production and maintenance.

Operational Monitoring Made Available in MaintMaster

Measure OEE and Manage Downtime

Stay in Control with Real-Time Operational Monitoring

By integrating operational monitoring directly into MaintMaster, you gain access to valuable insights. We calculate OEE and overall equipment effectiveness (OEE) and provide you with the tools to track and manage disruptions in a structured way.

Report what has been done, and MaintMaster will calculate the overall equipment effectiveness for you.

If an issue arises, forward the case directly to the maintenance team so they can resolve it quickly.

Continuous Improvement with MaintMaster

At MaintMaster, we believe in continuous improvement. By creating and maintaining a shared view of production and maintenance, we provide you with the right information at the right time and equip you with the tools for ongoing optimisation.

Take control of your production and maintenance processes by creating a unified picture with MaintMaster.

We deliver the right information at the right time to help you optimise your processes.

Choose MaintMaster and change the game today. 👊

Learn More About MaintMaster

ROI Calculator - Calculate your ROI with MaintMaster

How to choose a CMMS [Guide]

TPM (Total Productive Maintenance)

Read selected stories from our customers

CooperVision makes a 20% OEE gain by improving changeover efficiency

Müller Milk & Ingredients Increases OEE by 10% with Real-time data

Automotive Components Floby Ab - Integrate MaintMaster