Downtime reduction

Control maintenance and production like a pro

The simple codeless CMMS for manufacturing teams built by maintenance experts.

A CMMS just the way you want it

Simple to use

Learn and use the system within minutes, whether you're in the office or on the floor, this CMMS is incredibly easy to use.

Codeless customisation

Create custom views, fields, and reports with a few clicks by yourself, no tickets or developers required.

Backed by maintenance experts

Get support from former maintenance managers who know your industry and the CMMS inside out.

The old way burns hours.

The new way drives output.

Fewer clicks. Real adoption. More uptime.

Forget developers and change anything

Improvements die in the backlog when tweaks take weeks. Maintmaster CMMS starts from the EN Maintenance Standards and lets you customise everything.

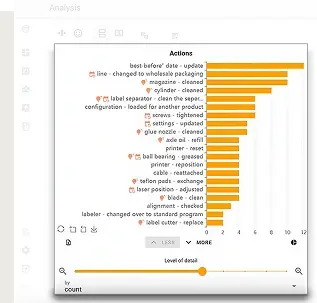

AI powered Manufacturing Intelligence

By analysing live production and historical data, Maintmaster MI detects risks, predicts failures, and recommends the right actions.

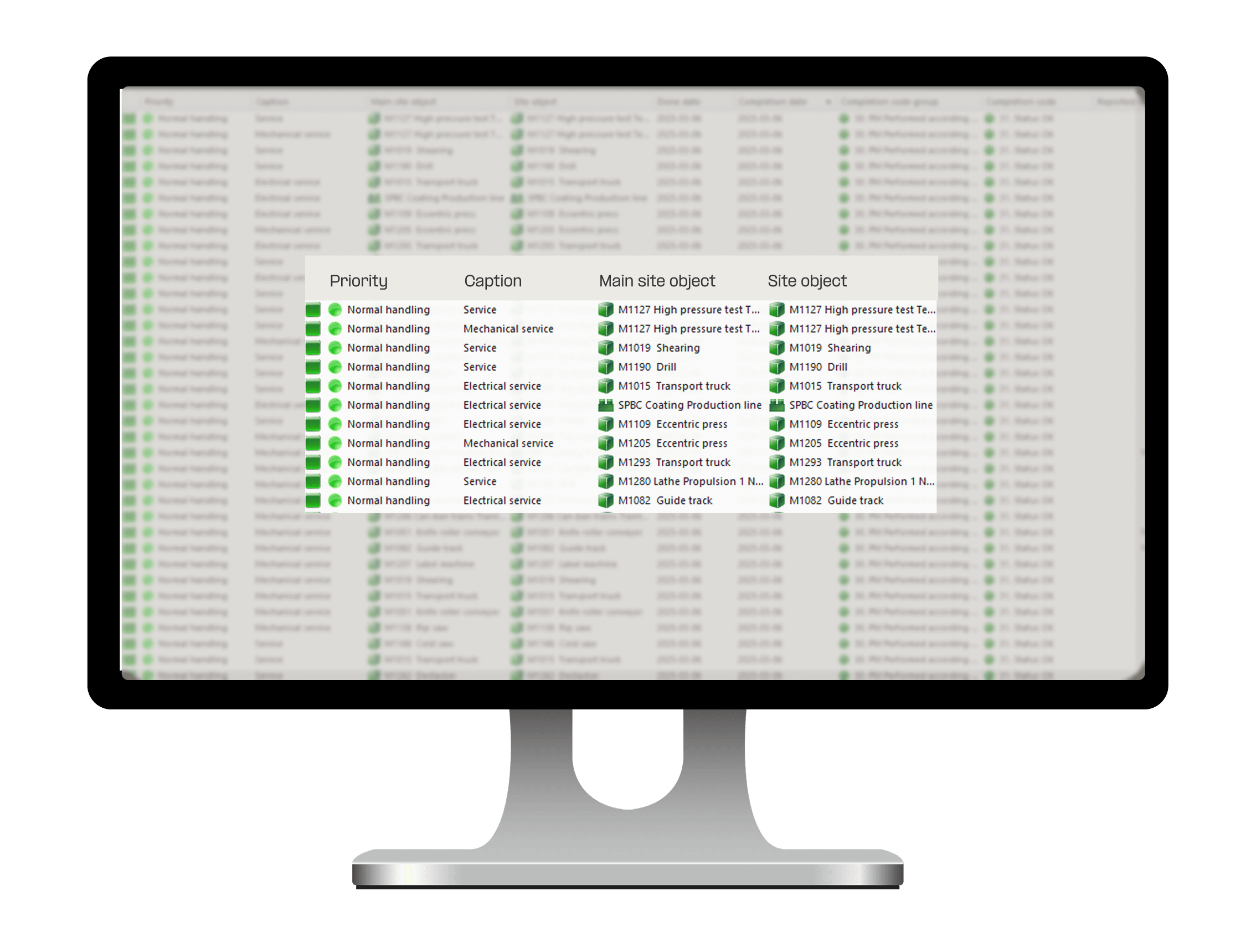

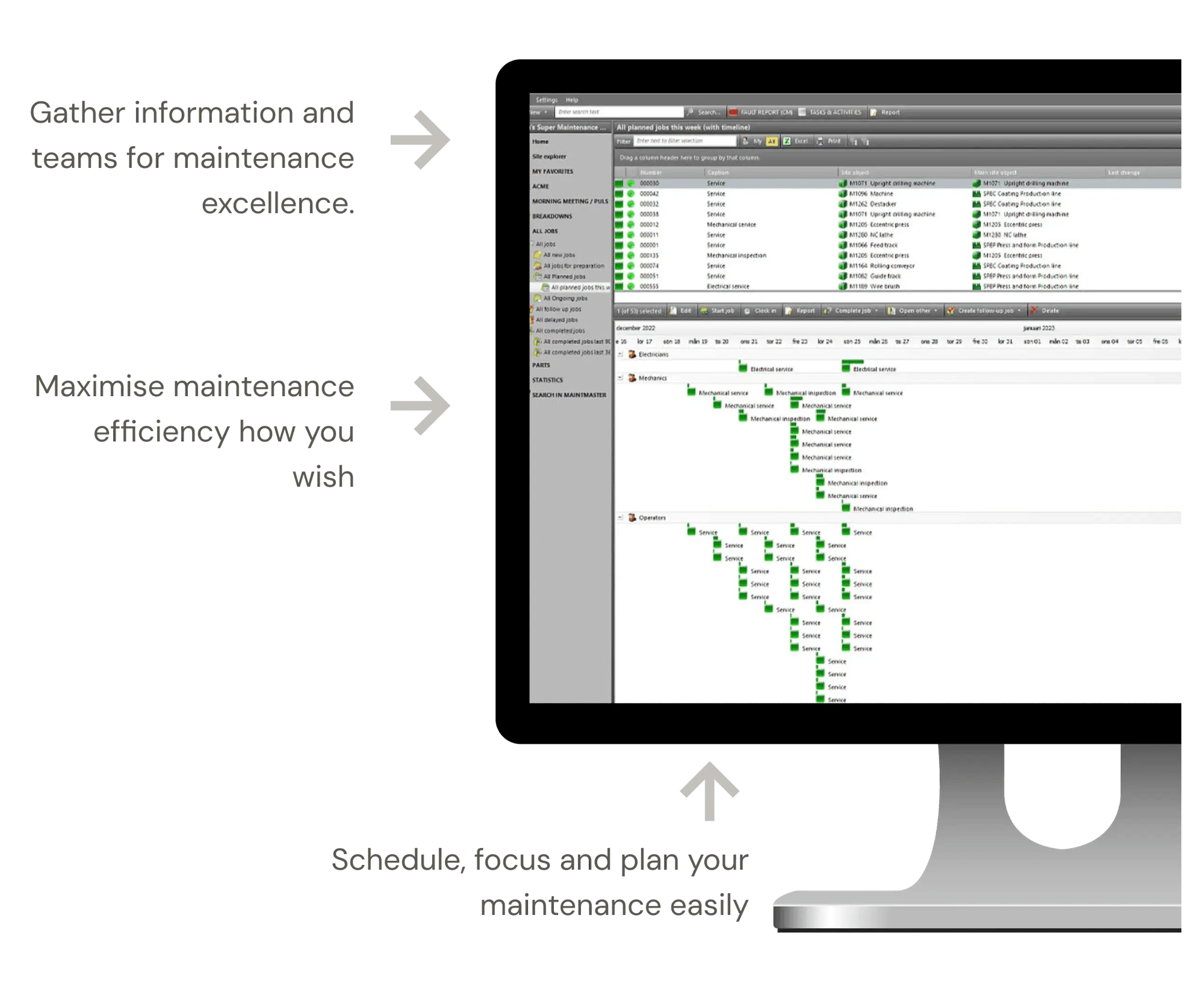

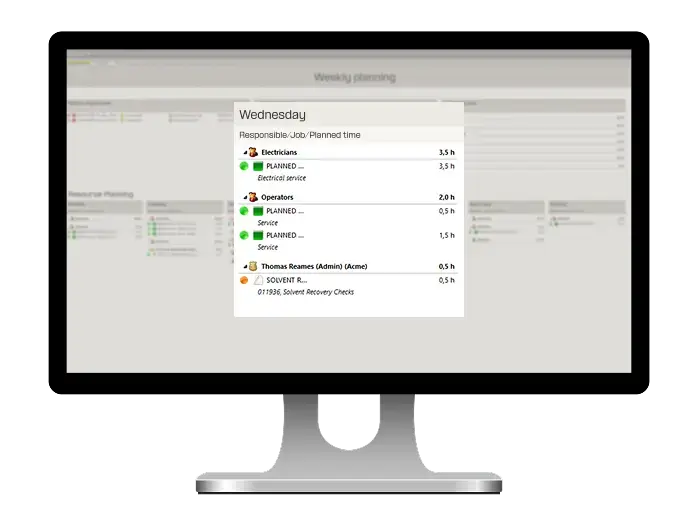

Replace confusion with balanced workload

When work lives in chats and whiteboards, no one knows who’s doing what. See every schedule at a glance, drag jobs where they fit, and keep your teams in sync.

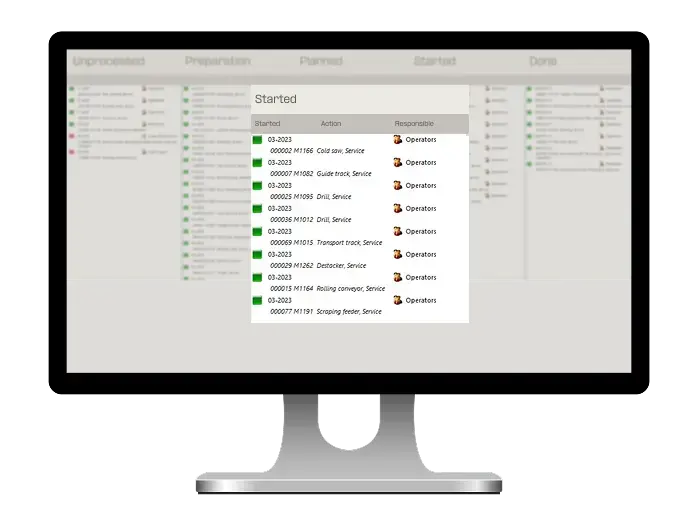

Go from random to following every step

Only working from memory or habit skips steps and makes standards drift. Ensure technicians follow clear checklists, with each job fully recorded from start to finish.

Personalised shortcuts for everyone

Customised individual views give every team member a clear workspace tailored to their needs, helping simplify planning, boost job efficiency, and monitor equipment performance with ease.

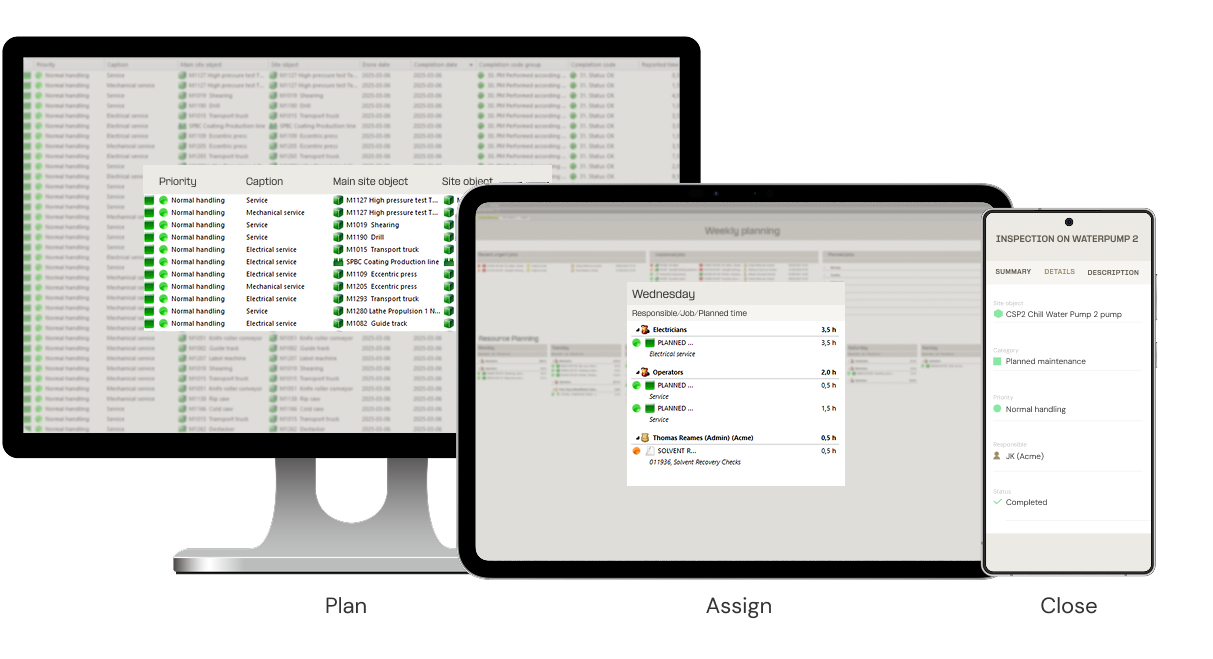

From spreadsheet overwhelm to one view

When maintenance runs on spreadsheets, information scatters and updates fall behind. Get one clear view with everything in one place, and templates, images, and manuals ready when you need them.

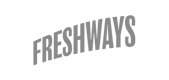

Workflow

Plan, assign and close work

in three steps.

01.

Plan

Plan jobs and adjust schedules to keep every task on track and your maintenance running smoothly.

02.

Assign

Easily set the right owner, due date, and required parts — ensuring every job is clear, accountable, and completed on time.

03.

Close

Everything captured automatically — downtime, checklists, photos, time, and parts for complete traceability.

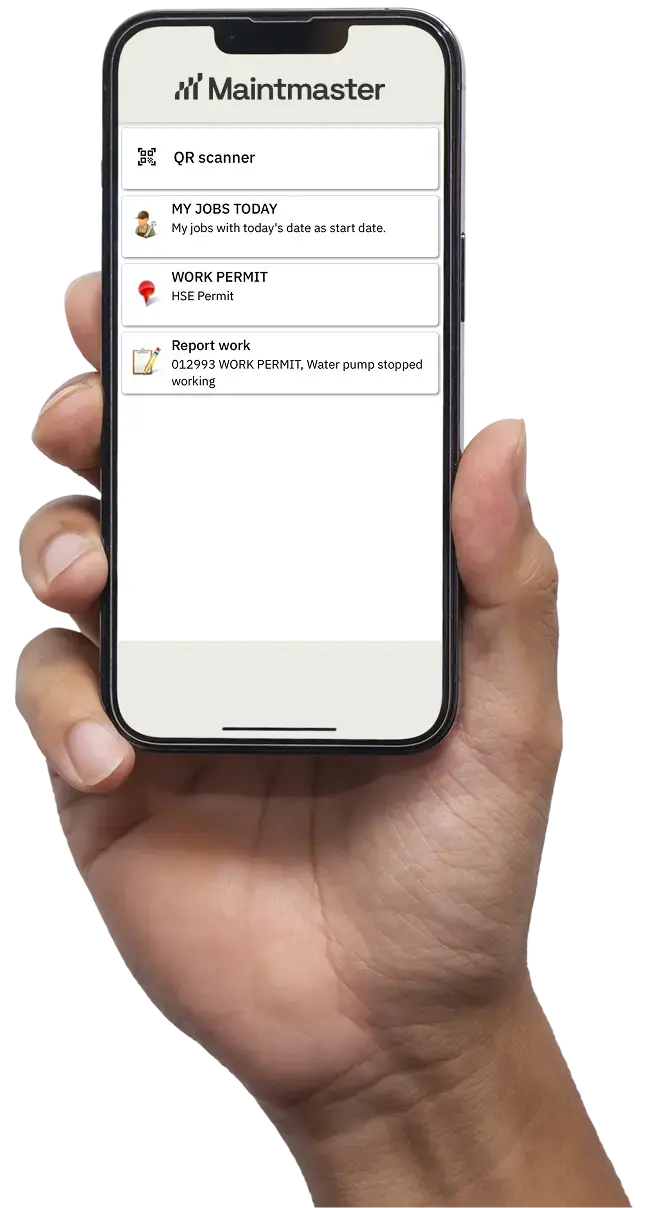

Mobile maintenance

Complete control in

every pocket

Access every tool

when you need it

Decide the tools and view for every user with shortcuts you can change in a simple tap.

Get all permits

at your fingertips

Create custom views, fields, and reports with a few clicks by yourself, no tickets or developers required.

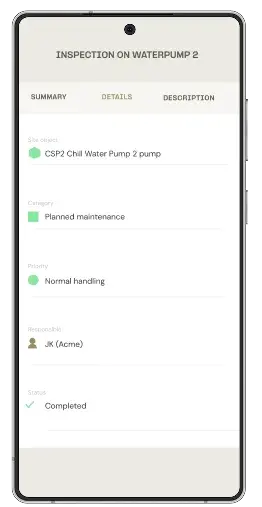

Do your inspections

on the go

Add photos, comments, and signatures directly on mobile for faster, more accurate reporting.

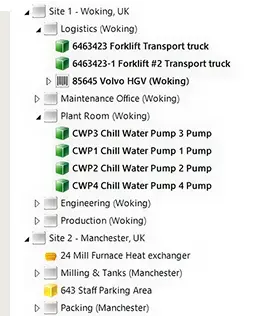

Asset structure

Clear structure

across your sites

Multi site structure

Need one provider that supports multiple sites? With adopting the same structure you are able to get full control over everything, within one system.

Every record is categorised

Add sub-levels and custom fields to match your own terminology and workflows, keeping everything structured, searchable, and consistent across the site.

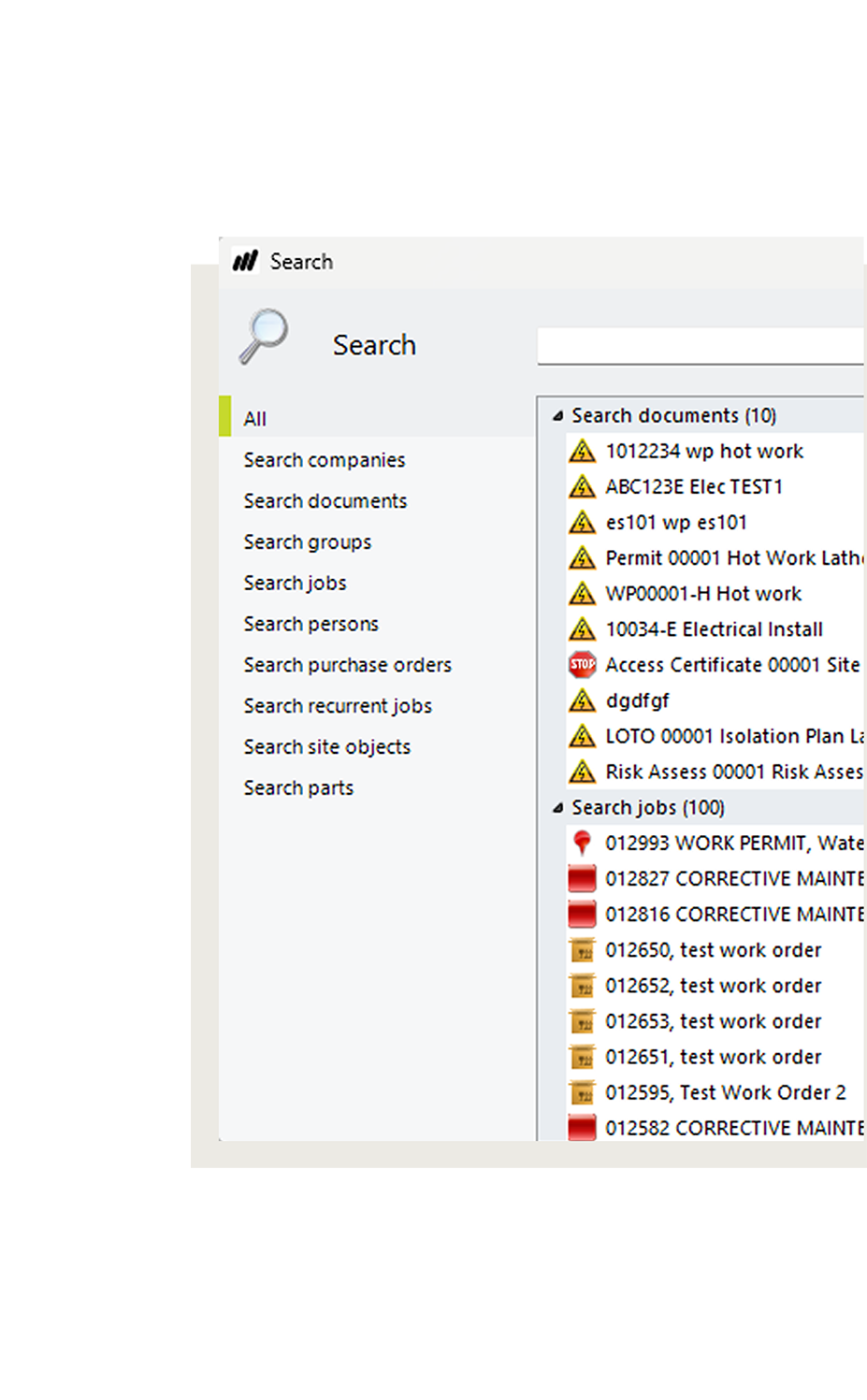

Navigate assets with clicks

Point and click from plant and area to machine or asset down to the smallest spare parts.

Or use the search bar if you already know what you're looking for.

Move it, track it

Limitless collaboration between maintenance and production. Need to move a part? Move it, track it, and report it from the same system.

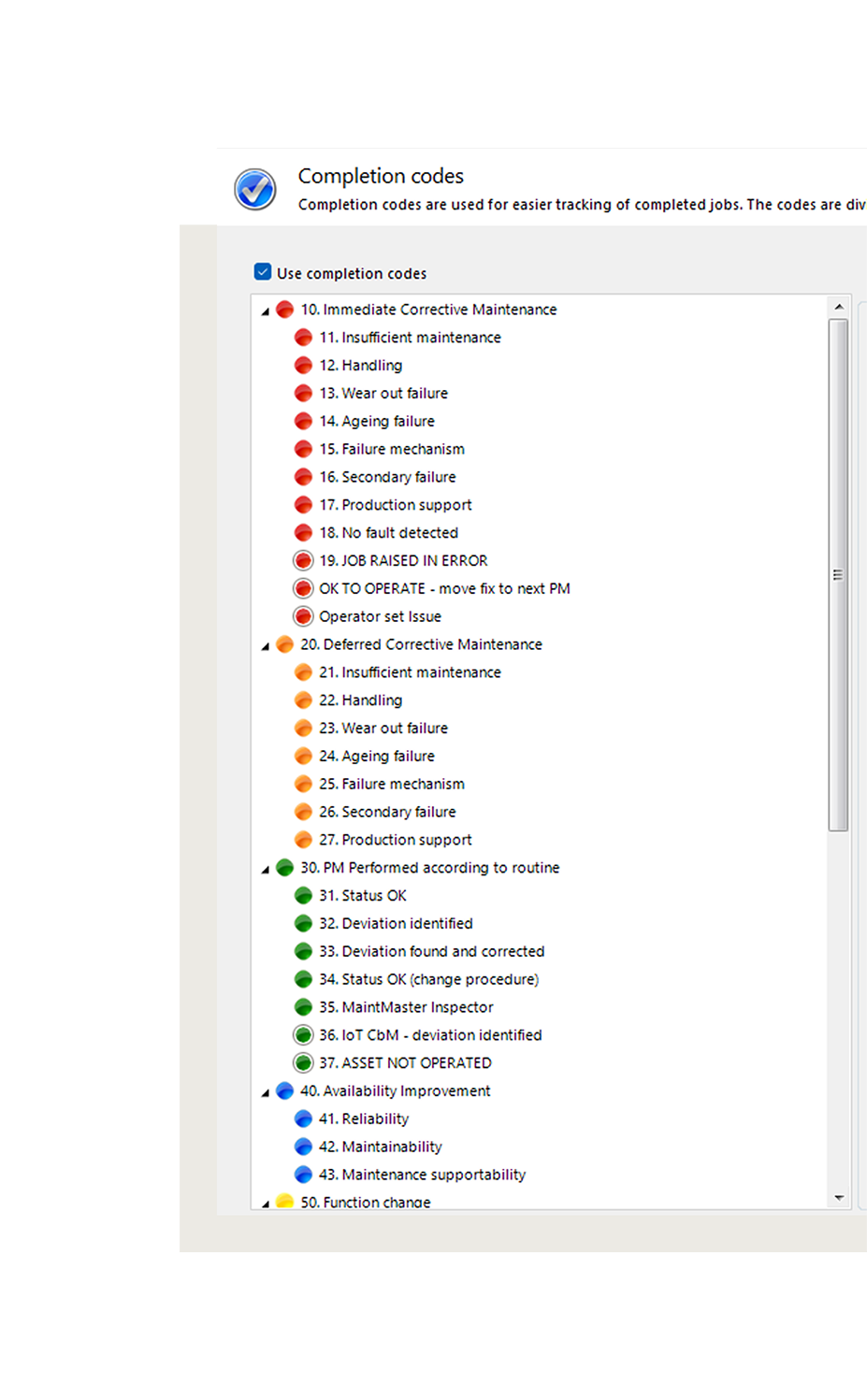

Pre-configured standard

Built on the EN 13306 standard, ready to use from day one, and easy to customise to your way of working.

1 000 or 100 000 assets?

Find information from any device and with instant access to work orders, permits, documents, images, and details on one screen.

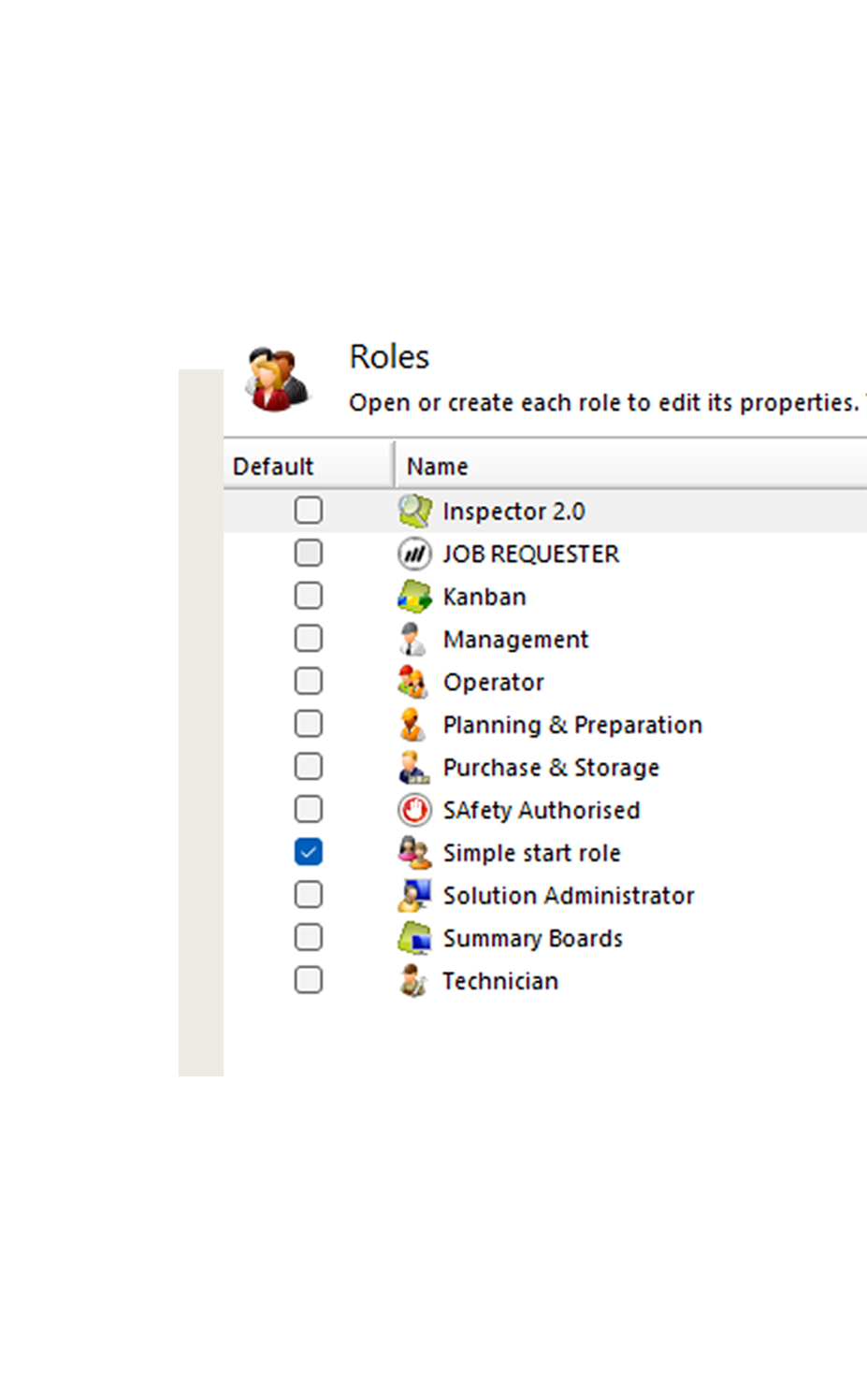

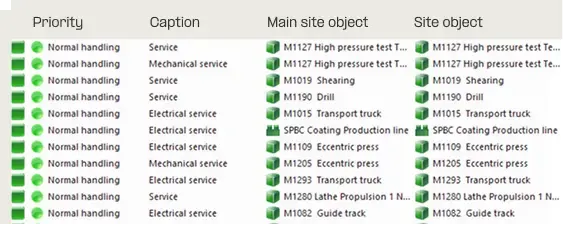

Tailor access to every role

With flexible permissions, you can adapt the asset structure so operators, technicians, managers, and auditors only see what’s relevant to their role.

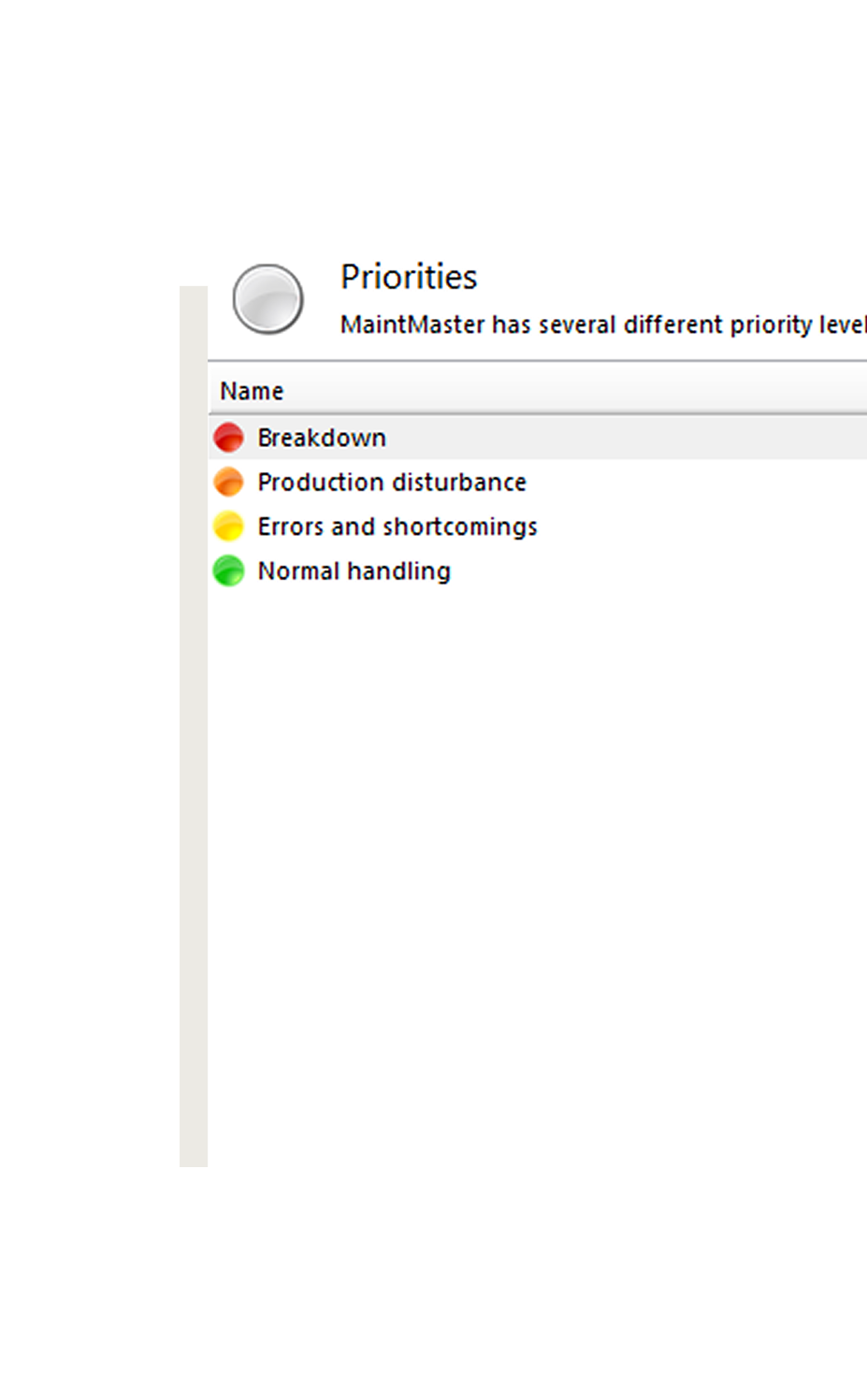

Configure your own priority levels

Define and manage different job priorities so your team always knows what needs attention first.

Reporting

The KPI you need

when you need it.

Maintenance cost per month

Your KPI, your way

Choose and track popular KPIs or build ones that suit your needs.

Reports in seconds

Create reports from any data source, customise filters and fields, and view results instantly

See every step on every job

Every action is automatically logged, and can be broken down into measurable data creating full traceability.

Break down your numbers, not your site

Make data your strongest decision tool. Get complete visibility, whether you’re reviewing long-term KPIs or analysing a single asset so you can analyse, act, and improve with confidence.

Create your own fields

- and report on it

You're not limited to predefined data. Every KPI can be built around your own processes, workflows, and priorities. Simply create custom fields for anything from safety checks, inspections to special projects and turn them into measurable insights.

Always ready for audits

Every job, signature, permit and photo is captured in real time. So you can prove compliance anytime, without manual work.

Audit ready within a few clicks

Every industry has its own audit requirements, and Maintmaster CMMS adapts to them all. Once the right data is collected in the system you can instantly generate the reports you need.

Predefined KPI:s - If you need it

Maintmaster CMMS comes with a library of ready-to-use KPIs designed by maintenance experts. You can use them as they are, or customise and extend them with your own fields to match how your maintenance really works.

One setup, any time range

Build your KPI once — and reuse it for any time period, so you don’t need to create new reports every time

Spare parts management

Spare Parts,

finally under control

Keep every part organised, traceable, and ready when you need it.

Track stock levels, locations, usage, and reorder points — so maintenance never stops because a part is missing.

Always find what you need

View all spare parts, stock levels, criticality, and lead times in one real-time view to plan maintenance and purchasing with confidence.

Link spare parts to objects

See all spare parts linked to site objects in detail, so you always know which equipment needs them before planning maintenance.

Empty shelves?

Fix lacking inventory by creating a purchase order within the system to clearly overview price, lead time and inventory.

Overview on inventory

See stock balance, price and reorder point, storage location and criticality, and full identification details like number, name and designation in the overview.

Shelf warmers

Identify and act on shelf warmers instantly so you can free up budget and space for the parts that actually keep production running.

Planned parts

See all planned parts for every job in one view so every maintenance task is ready to start on time.

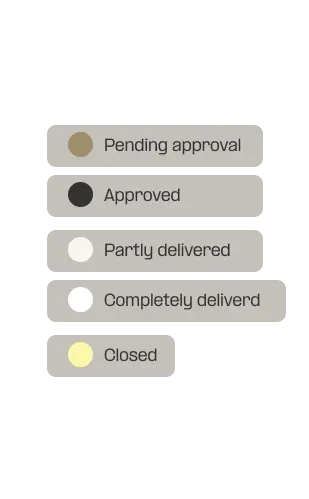

Status on purchase orders

See the status of every purchase order in one view to keep maintenance running on schedule.

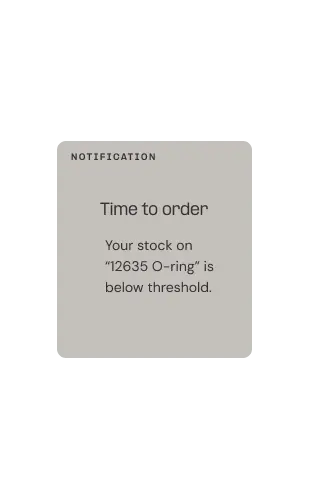

Low stock?

Get notified when stock drops below threshold to prevent stockouts.Scheduling

The right people on

the right job

Forget complex systems

Plan, prioritise, and optimise maintenance to perfection with zero technical expertise.

See days in one view

Use the summary boards for structured workflows and a crystal clear daily agenda.

Make everything yours

Design your summary board freely to see the information and tasks you want to see.

Visibility of compliance metrics

Increased productivity

Fewer admin hours

Data working together

Power up your

maintenance stack

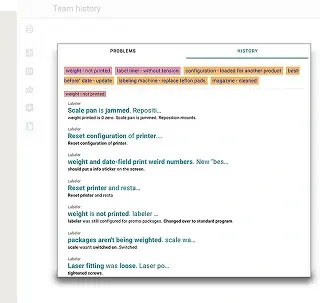

Maintmaster Manufacturing

Intelligence powered by AI

With Manufacturing Intelligence, your team notes gather intelligence around the clock, so you can make better decisions for high uptime and output.

See missing patterns

Interpret notes like “mttr pump L3” or “sensor trippin” automatically with grouping for similar notes into recurring issues across shifts, lines, and sites.

Start fixes faster

Get recommended actions based on previous fixes for every problem so technicians can start repairs instantly.

Find problems easily

Cut trial-and-error with real guidance and proven solutions for quicker fixes, reduced downtime, and fewer recurring failures.

Expand your CMMS with Maintmaster OEE

Connect the CMMS with MaintMaster OEE for a seamless data flow that keeps production and maintenance in sync and all events on your lines visible, tracked, and visualised.

We are here to

support your journey

At Maintmaster, we believe that maintenance makes a real difference, driving productivity, sustainability, and safety across your operations.

To unlock these opportunities, we want you to be in control — of your tool, your processes, and ultimately, your business.

Our implementation projects are designed with that in mind. Using a “train-the-trainer” approach, we guide your team through seven structured steps that build confidence and independence.

And the best part? You’ll be up and running after the very first step.

Years of experience

Implementations across 39 countries

On-site visits, if you need

Discover our use cases

Production & Maintenance Alignment

Boost uptime and efficiency with seamless alignment between maintenance and production.

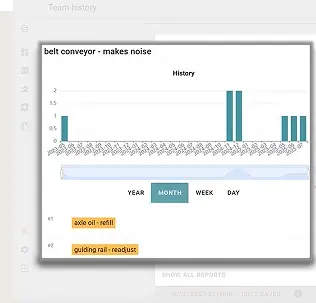

Maintenance Alerts & Analysis

Identify issues early, prevent unplanned downtime, and move from reactive to proactive maintenance.

Audits & Compliance

Digitise maintenance, ensure compliance, and stay audit-ready without slowing production.

Operator Maintenance

Structure, scale, and optimise operator maintenance to boost efficiency and maximise plant availability.

IoT Sensors

Monitor equipment conditions in real time with pre-configured gateways and sensors that integrate seamlessly with your CMMS. Simple to set up and ready to use.

CMMS & AI

Turn maintenance data into clear, actionable insights. Helping teams spot patterns, solve root causes, and improve reliability.

Learn more

Connect manufacturing excellence

Integrate your existing systems like accounts, stock, suppliers, or purchasing with expert roadmaps and flawless functionality.

Learn more about our integrations

Global stories of success

Great customers are the foundation of a great product. Born in Sweden and trusted all around the globe.

Today, we’re used in 39 countries and available in 20+ languages, helping teams shape safer, smarter, and more efficient production.

From ERP module to Maintmaster CMMS

“We were in need of a new maintenance system because the old system was more of a module in an ERP system and not a real maintenance system.”

- Niclas Hult, Maintenance Manager

![]()

Siva Group scales with Maintmaster CMMS

“Maintmaster CMMS is significantly different from the vast majority of CMMS systems, largely because of its modular nature and the way in which you can embark on the journey with MaintMaster and take your organisation with it.”

- Steve Burnage, Head of Engineering,

![]()

Cornish Lithium unlocks growth with Maintmaster CMMS

"With MaintMaster, you don't have to use any preloaded system or structure. "It's a blank canvas for you to adapt to how you want to use it."

- Daniel Vincent, Maintenance Planner

Baosteel goes digital with Maintmaster CMMS

“What I like about MaintMaster is that we can customise the layout of the interface so that Maintenance sees one thing and production sees another.”

- Kalle Larsson, Technical & Maintenance manager.

![]()