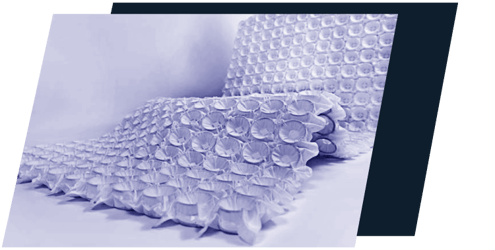

Starsprings manufactures spring forms, found in matrasses. In 2006 they founded their plant in Poznan, Poland. MaintMaster has been the maintenance system used at the plant in Poland since 2018.

From excel to MaintMaster

Artur Pawlak is maintenance manager and has been involved since the implementation of MaintMaster CMMS. Along with his maintenance team of 8 people, he uses MaintMaster on an everyday basis.

"Before MaintMaster, we used Microsoft Excel to keep track of our maintenance. The big difference today is the history log in MaintMaster. We use it a lot to check how we solved issues that have occurred before, and this has reduced downtime and our MTTR"

Once a year, production is paused for two weeks so that the maintenance team can perform essential tasks. Also, a lot of preventive maintenance is carried out on Saturdays when there’s no production.

– I believe we’ve increased our preventive maintenance a little using MaintMaster, but as I mentioned, the most important part for us turned out to be the history log. Being able to see what we’ve done previously.

The implementation of MaintMaster was done together with TransTeka, a MaintMaster partner located in Poland. They enabled Starsprings to do all the training at its plant. This was much appreciated by Artur Palwak and his team.

– I’ve always felt I’ve gotten the support needed, not only from TransTeka but also from MaintMaster employees in Sweden. I’m the kind of person who learns on the job by doing things. Being able to try new ideas in MaintMaster easily is one of the system’s biggest strengths. And one of the highlights for me is the site explorer and the ability to design it from the department level all the way down to the spare parts associated with a single machine. Together with my colleague Marcin Kiełpiński, production manager, we’ve created a very appreciated and user friendly site explorer.

Artur continues:

– With that said, if I had the chance to make this journey all over again, there’s a few things I’d do differently. But overall, I’m very pleased with the implementation and with the program.

Here are a few tips from Artur

1. When implementing MaintMaster, set up a goal for how you want to use it and plan, step by step, how to get there.

2. Let the maintenance team start using it for reporting as soon as possible. This will not only give you a nice history log, but also a great understanding of what your team does or does not appreciate.

3. Once you get your team making reports, start using it for statistics to see if there’s anything you need to change in the reports to get the right KPIs.

* MTTR – a KPI to measure the Mean Time To Repair.