In many companies, Total Productive Maintenance (TPM) is no longer a foreign word. More frequently, the topic comes across the desk of production and maintenance managers and requires time and attention. The challenge for production and maintenance is to implement TPM in a reasonable way and fill it with life.

Total Productive Maintenance - Challenges in implementation

When implementing TPM actions, it quickly becomes clear that asking production to carry out minor maintenance activities themselves raises questions of structure and orientation.

It is extremely important that employees and colleagues from production do not act without the guidance and help of maintenance. For example, documentation and proof must be kept permanently available; not only during an audit but always. Total Productive Maintenance should increase the actual availability of machines, and not just supply audits.

Requirements for maintenance departments

From our point of view, this means that maintenance departments must always have the following things on hand:

- Work instructions

- Work orders

- Management of planned, recurring appointments

- Follow-up on execution or overdue dates

- Documentation of execution with name and time

- Possibility to analyse the documentation

From Excel lists to maintenance software

In many companies, these requirements are processed with Excel tables or lists on paper. This is an important first step, but it cannot be implemented on a long-term basis. It is more effective to map these in the maintenance software so that the necessary consistency is achieved in the long term.

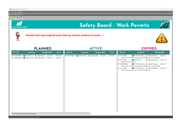

TPM activities in MaintMaster

MaintMaster, as a CMMS, is definitely the first place to think of when you want to roll out your TPM activities into production.

The MaintMaster CMMS covers all maintenance topics. So why not also the TPM activities? Nothing is better suited for this. To make this work without effort, MaintMaster as a digital tool supports all the above requirements more easily and much more efficiently than manually maintained tables can.

TPM - The advantages of a CMMS

- Work instructions: Specifications by you, simply multiply, re-use repeatedly

- Management of planned, recurring appointments: Set recurring deadlines, and never forget

- Follow-up on execution or overdue dates: Show status check and overdue items automatically

- Documentation of execution with name and time: User and time stamps on digital documents simplify your audit and evidence

- Possibility to analyse the documentation: Filter by the result, display statistics automatically and export if required

Of course, you can take care of even more functions such as time budget specifications for the TPM activities and the recording of the time actually worked at the same time. Your TPM processes are simply mapped in MaintMaster and you have all the options for digital evaluation.

In MaintMaster you can create work instructions, timed work requests, recurring appointments and much more. All actions taken can be documented, tracked and analysed over time for improvement needs.

Production and maintenance work together

Another advantage is that by jointly using MaintMaster, production and maintenance can have better communication with each other. So it will also no longer happen that maintenance tasks are carried out twice or that maintenance does not know which maintenance work has already been carried out as part of TPM.

The use of a CMMS provides companies that want to implement Total Productive Maintenance with the ideal tool.

You can test our CMMS right away for 30 days completely free of charge and without obligation: