Whether planning preventive maintenance or managing daily operations, effective scheduling helps keep your equipment running without stopping and avoids expensive downtime.

The importance of the right job expertise

Maintenance excellence is impossible without scheduling. But it’s not only about putting work on a calendar. It’s about ensuring the right people are in the right place at the right time.

Skilled and experienced technicians help identify and fix potential issues on your machines before they become big problems. But having these technicians on your team isn't enough. You must ensure they know what job to do, which asset, and at what time.

For example, let's say you have preventive maintenance work scheduled for a critical piece of equipment. The job requires skills that only a few technicians on your team have. But on the day of the task, those technicians are all tied up with other work orders.

The work is either delayed or assigned to someone without the necessary skills, resulting in subpar work or equipment failure. Now that's a big problem.

Why time is of the essence

Understanding your team's skills and availability is key to effective maintenance scheduling. That helps you ensure that the right people get the right tasks, which helps prevent issues and keep your equipment running smoothly.

But scheduling maintenance is also about doing maintenance at the right time. For example, maintenance during a production run can result in costly downtime. On the other hand, scheduling a task during off-hours can ensure that equipment is ready to go when production starts back up.

This proactivity is why it's important to consider the production schedule when scheduling maintenance tasks. Doing so can ensure the technician does the job at the best possible time. That minimises downtime and maximises productivity in your maintenance department.

Summary

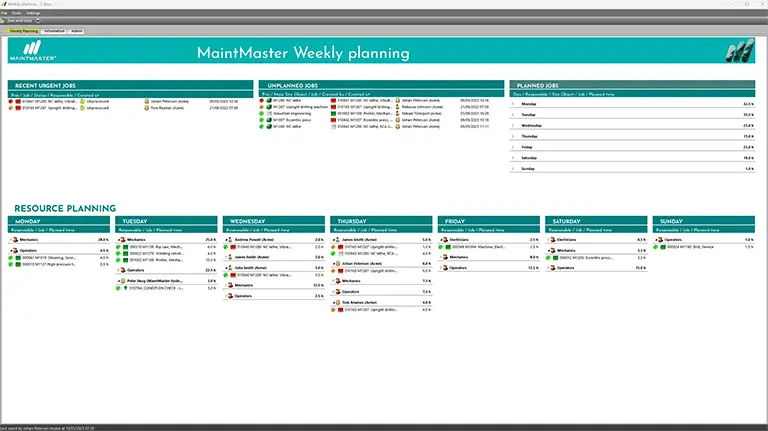

The greatest benefit of digitalising your maintenance and scheduling is that everything becomes easier and less stressful. No more running around asking what needs to get done, when the worker will finish their jobs, or what spare parts need changing. You’ll even know that the people with the right competencies are on location, ready to work.

Maintenance can indeed be tricky. But it deserves high recognition since keeping production and the company running is essential. That's why MaintMaster's mission is to make you the company hero by supporting, visualising, and automating tasks – with all the information you need in the palm of your hand.

The CMMS solution gives you the tools to structure your planning by associating tasks with the right teams or people when you discover them.