Chapter 2

Top 3 KPI Manual

…that no maintenance department should BE without!

When it comes to maintenance however standardised KPIs need to be evaluated carefully. Measuring the performance of people without careful consideration can lead to unpredicted behavior.

KPIs always assume a temporal perspective. They should never be seen as a static number but rather take into account the development over time. The term Key Performance Indicator in its parts hints towards a scaling of the observation period: Performance indicators are seen as a shorter-term perspective whereas Key Performance Indicators assume a more long-term perspective. For the sake of simplicity, we will use the term “KPI” for all calculations independent of their assumed observation period.

Each KPI can in most cases be calculated on a variety of entities such as people, objects or departments and on a variety of units such as instances, hours or costs. Provided that the data is accessible, MaintMaster can calculate the KPIs whichever way desired but it remains up to the customer to decide which mode of calculation is the most promising.

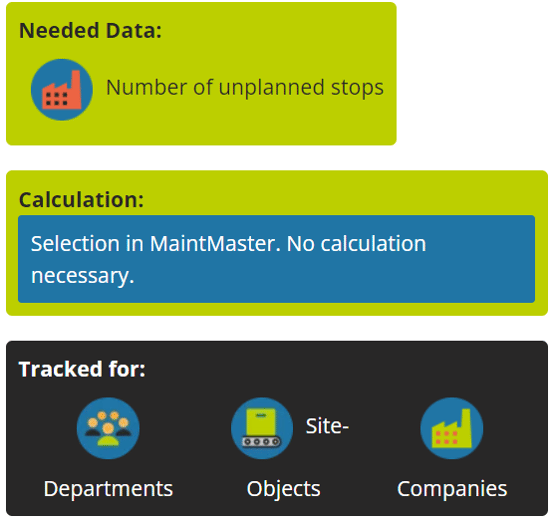

#1: Number of unplanned stops

How often are unplanned stops occurring?

The number of unplanned stops is the simplest and most powerful KPI that you can use. It gives you a clear direction on what to improve. The less unplanned stops you have, the better.

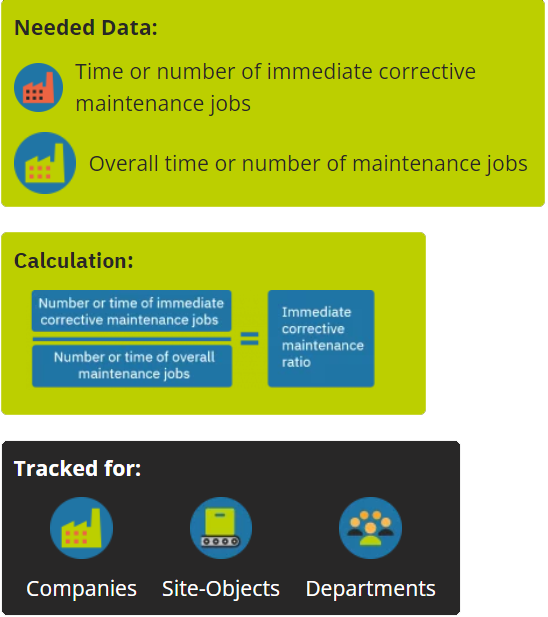

#2: Immediate corrective maintenance ratio

How much immediate corrective maintenance is done in relation to all other maintenance activities?

Immediate corrective maintenance means that the team has to respond NOW – Often because it causes production stop or because there are safety issues involved. These tasks are often accompanied by emergency deliveries and other costly measures and have a negative effect on the stress level of the maintenance team.

You can really get a sense of how well the maintenance organisation and production equipment are doing by tracking the number of immediate corrective maintenance tasks. Tip: If you also report downtime in your immediate corrective maintenance jobs and track it in another KPI, you will get even better opportunities to identify the biggest shortcomings regarding reliability on your production equipment.

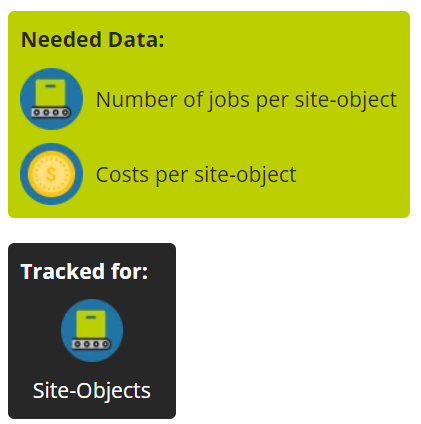

#3: Top 5 site-objects

Which objects are causing the most trouble?

Site-Objects need to be traced both in terms of their maintenance costs but also for the number of jobs created on them. Tracking both these aspects will create a clear picture as to which Site-objects (machines, equipment, assets, buildings, lines …) are the most resource-demanding. The intention is that these Site-objects will change over time due to renovations, improvements and investments based on this KPI.

Maintmaster KPI Manual

Improve your maintenance strategy by using Key Performance Indicators (KPIs) to track and optimise your operations. Download our comprehensive manual to get started.