Chapter 5

Energy & Environment

ISO 50001 and ISO 14001

ISO 50001 and ISO 14001 are two important certification and auditing standards for energy and environmental management. ISO 50001 provides a framework for organisations to systematically manage and improve their energy performance, including energy consumption, efficiency and sustainability. ISO 14001 provides a systematic approach to managing an organisation's environmental responsibilities and impacts.

Achieving these certifications demonstrates a company's commitment to energy efficiency, environmental responsibility and sustainability. Companies that meet the requirements of both ISO 50001 and ISO 14001 can enhance their reputation, improve their overall performance and increase their competitiveness in the marketplace.

Certifications and audits:

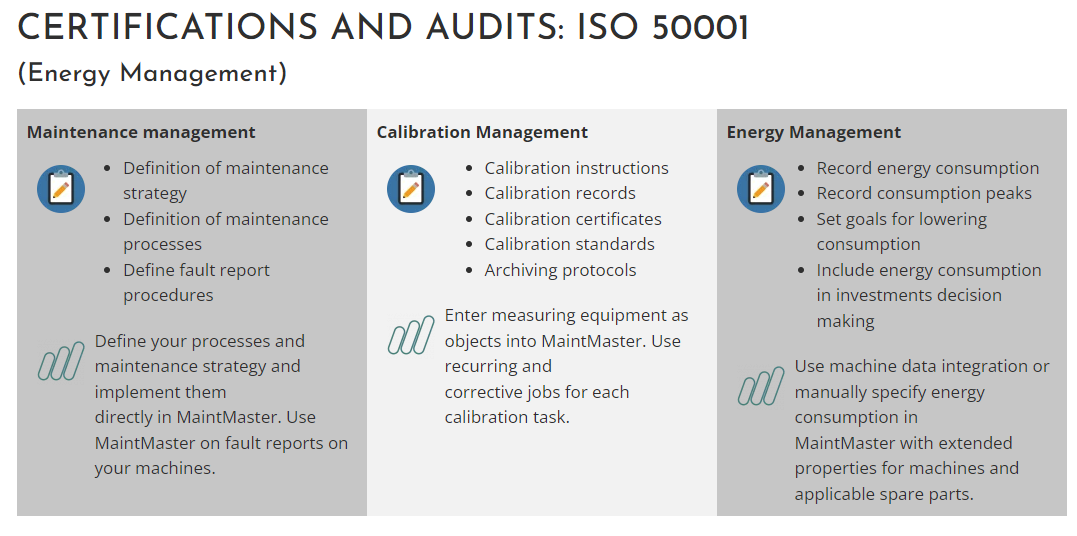

Energy management/ISO 50001

Maintenance management

Maintenance management is a critical component of production processes and involves defining a maintenance strategy, establishing maintenance processes and outlining fault reporting procedures. A well-defined maintenance strategy helps to ensure that equipment and facilities are properly maintained, reducing the risk of breakdowns and unplanned downtime.

Establishing maintenance processes outlines the steps that should be taken to maintain equipment and facilities, including schedules, procedures and responsibilities. Failure reporting procedures provide a clear process for reporting and documenting any malfunctions or failures, which is essential to ensure that problems are quickly addressed and resolved. By implementing a comprehensive maintenance management programme, companies can optimise the performance and reliability of their production processes, reducing costs and improving their bottom line.

How Maintmaster will help

Maintmaster is a CMMS that helps to implement and manage maintenance processes and strategies. With Maintmaster, organisations can define their processes and maintenance strategy and implement them directly into the system. This ensures that maintenance activities are carried out consistently and effectively, and that all relevant information is readily available for decision making and analysis.

Maintmaster also provides a streamlined process for fault reporting, allowing companies to document and manage issues with their machinery in real time. By using Maintmaster for maintenance management, companies can improve the efficiency and reliability of their production processes, reduce downtime and optimise their maintenance activities. Whether you're looking to optimise your maintenance processes or streamline your fault reporting procedures, Maintmaster is the solution you need to achieve your goals.

Calibration management

Calibration management is an important part of ensuring the accuracy and reliability of production processes. It involves the maintenance of calibration instructions, records, certificates and standards, and the implementation of effective archiving protocols. Calibration instructions outline the procedures that should be followed to calibrate equipment and maintain accuracy over time.

The results of calibration activities are documented in calibration records, which serve as a record of equipment performance. Calibration certificates provide a formal record of calibration results, and calibration standards ensure that equipment is calibrated to the correct specifications. Archiving protocols provide a process for securely storing and managing calibration records, certificates and standards over time.

How Maintmaster will help

Maintmaster provides a comprehensive calibration management solution. Companies can easily enter their measuring equipment as objects into the system and use recurring and corrective jobs to manage each calibration task. The system provides a clear and straightforward process for scheduling and tracking calibration activities, and for documenting and reporting calibration results. MaintMaster also provides a centralised repository for calibration records, certificates and standards, making it easy to store and manage these important documents over time.

Whether you're looking to streamline your calibration processes, improve accuracy and reliability, or meet compliance requirements, Maintmaster provides the tools and features you need to succeed. By using Maintmaster for calibration management, companies can improve the efficiency and effectiveness of their calibration processes, reduce the risk of failure and improve overall production performance.

Energy management

Effective energy management requires accurate and comprehensive energy consumption data. Organisations need to be able to track their energy consumption, monitor peak usage, set targets for reducing consumption and use energy consumption data to inform investment decisions. Accurate and timely energy consumption data enables companies to identify opportunities to reduce energy consumption and track progress towards their energy reduction goals.

It also provides a basis for making informed decisions about investments in energy-saving technologies and practices. By implementing a robust energy management programme that includes comprehensive energy consumption data and analysis, organisations can reduce their energy costs, improve their energy efficiency and enhance their overall sustainability and competitiveness.

How Maintmaster will help

Maintmaster provides a flexible and comprehensive solution for recording and analysing energy consumption. Companies can use machine data integration to automatically collect energy consumption data, or manually specify energy consumption data using advanced properties for machines and associated spare parts. The system provides a centralised repository for energy consumption data, making it easy to track and compare energy consumption over time.

Maintmaster also provides tools for setting and tracking energy reduction targets, monitoring consumption peaks and using energy consumption data to inform investment decisions. Whether you're looking to reduce energy costs, improve energy efficiency or increase your sustainability and competitiveness, Maintmaster provides the tools and features you need to succeed. By using Maintmaster for energy management, organisations can gain a deeper understanding of their energy usage, identify opportunities to reduce energy consumption, and make informed decisions about investing in energy-saving technologies and practices.

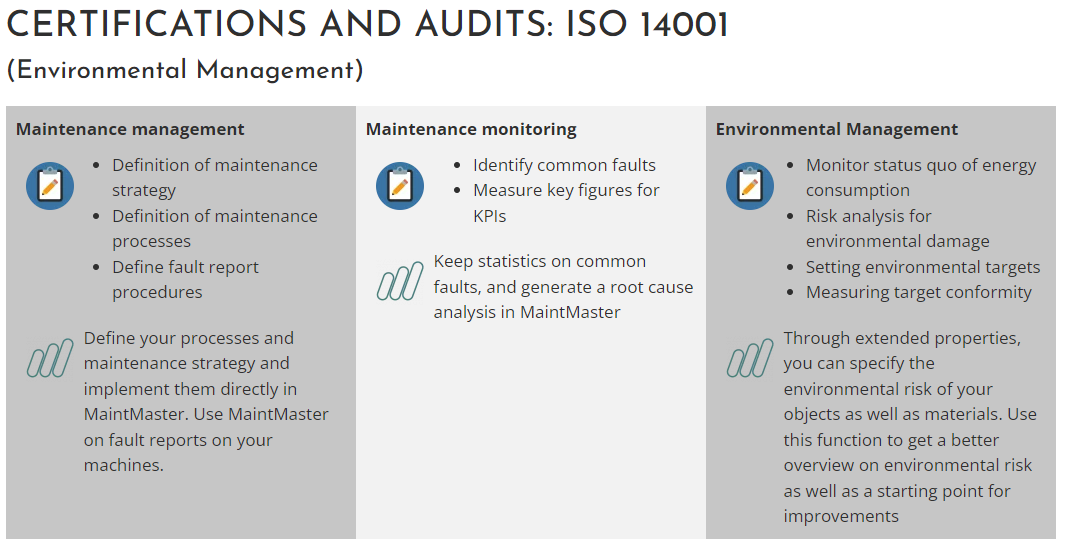

Certifications and audits: Environmental Management/ISO 14001

Maintenance management

Maintenance management plays a crucial role in production operations. It involves defining a maintenance strategy, establishing maintenance procedures and setting up fault reporting processes. A clear maintenance strategy helps to ensure that equipment and facilities are maintained effectively, reducing the likelihood of breakdowns and unplanned downtime.

Maintenance procedures detail the steps required for maintenance, including schedules, procedures and responsibilities. Malfunction reporting procedures provide a systematic way of reporting and recording malfunctions and failures, which is important for the prompt resolution of problems. Implementing an effective maintenance management programme can improve the performance and reliability of production processes, reduce costs and increase overall profitability.

How Maintmaster will help

Maintmaster is a Computerised Maintenance Management System (CMMS) designed to help organisations efficiently implement and manage maintenance processes and strategies. The system allows companies to define their maintenance processes and strategy and implement them directly within MaintMaster, ensuring consistency and effectiveness of maintenance activities and providing easy access to information for decision making and analysis.

Maintmaster also provides a simplified approach to fault reporting, enabling real-time documentation and management of machine issues. By using Maintmaster for maintenance management, companies can improve the efficiency and reliability of production processes, minimise downtime and optimise their maintenance operations. Whether you are looking to optimise maintenance processes or streamline fault reporting, Maintmaster provides the solution you need to achieve your goals.

Maintenance monitoring

Maintaining the performance and efficiency of production processes requires the monitoring and tracking of maintenance activities. Maintenance monitoring involves identifying common faults and measuring key performance indicators (KPIs) to determine the overall health and efficiency of production processes. This information can then be used to make data-driven decisions and improvements to the maintenance strategy, processes and procedures. By implementing effective maintenance monitoring, companies can ensure continuous optimisation of their production processes and minimise the risk of breakdowns and unplanned downtime.

How Maintmaster will help

Maintmaster can be used to track common faults and analyse the root causes of these problems. By keeping statistics on faults, you can identify trends and patterns that may be affecting the performance and reliability of your equipment. By generating a root cause analysis in Maintmaster, you can gain a deeper understanding of why faults are occurring and take action to prevent them from happening in the future. This helps to ensure that your maintenance activities are more effective and efficient and that your equipment runs smoothly and consistently.

Environmental management

Environmental management involves monitoring and managing the impact of a company's operations on the environment. This includes monitoring energy use to identify areas for improvement, conducting risk analysis to assess the potential for environmental harm, and setting environmental targets to drive progress towards sustainability goals. Measuring performance against targets helps to ensure that the company is on track to meet its environmental objectives and make continuous improvements over time.

How Maintmaster will help

Using the advanced properties feature in Maintmaster, you can categorise your items and materials based on their environmental risk. This allows you to gain a comprehensive understanding of the environmental risks associated with your equipment and supplies, and serves as a basis for identifying areas for improvement.

Maintmaster Audit handbook

Don't let the complexity of certification hold your business back. Use our comprehensive audit and certification guide and MaintMaster, the most flexible maintenance management software, to ensure your compliance with the most common certifications.

Enhance your maintenance department and ensure a successful future for your business.

Act now!

- 1. Why this handbook?

- 2. Management Systems - ISO 9001 & ISO 14001

- 3. Management Systems - ISO 45001

- 4. Management Systems - ISO 28000

- 5. Energy & Environment - ISO 50001 & ISO 14001

- 6. Automotive - IATF 16949

- 7. Food - FSC & BRC

- 8. Implementing Certifications with MaintMaster

- 9. Learn the basics of a CMMS