Chapter 2

Management Systems

ISO 9001, ISO 14001

Quality and environmental management

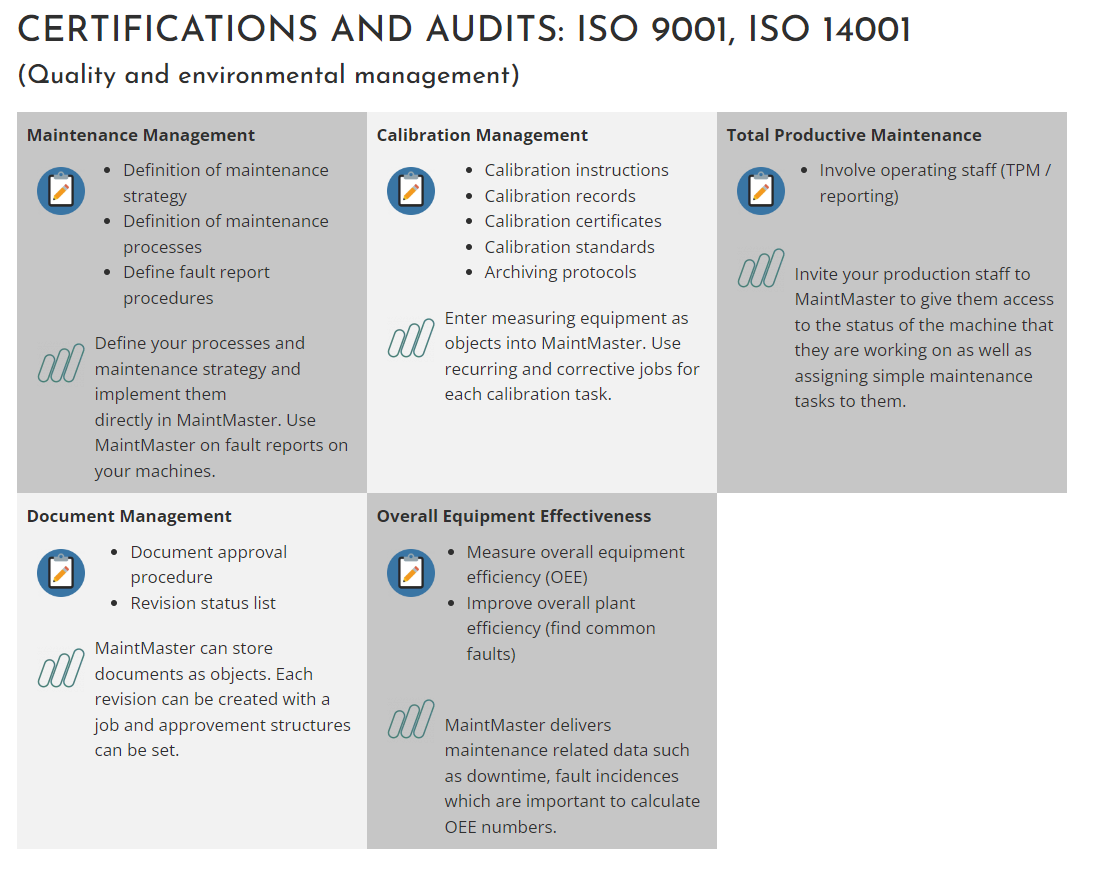

ISO 9001 and ISO 14001 are two important certifications that organisations can implement to achieve excellence in quality and environmental management. These standards provide a framework for organisations to improve their processes and operations, ensuring that they meet customer expectations and comply with environmental regulations. By implementing these management systems, organisations demonstrate their commitment to quality and environmental sustainability, enhancing their reputation and competitiveness in the marketplace.

Maintenance management

Effective maintenance management is essential for the smooth functioning of equipment and facilities. However, without a proper definition and implementation of a maintenance strategy and processes, problems will arise. To address these issues, it is important to have a clear definition of the following key elements:

-

Definition of Maintenance Strategy: A maintenance strategy outlines the approach taken to maintain equipment and facilities. This may include preventative maintenance, predictive maintenance, or a combination of both. A clear definition of the maintenance strategy is essential for consistent and effective maintenance management.

-

Definition of Maintenance Processes: Maintenance processes refer to the specific tasks and procedures carried out to maintain equipment and facilities. Proper definition and documentation of these processes are essential for consistency and efficiency in maintenance management.

-

Define Fault Report Procedures: Fault reporting procedures are an important part of maintenance management. They allow for the prompt identification of problems with equipment and facilities, which will then be addressed in a timely manner. Effective fault reporting procedures will help minimise the impact of equipment breakdowns on operations.

How Maintmaster will help

By using Maintmaster, organisations can implement their processes and strategy directly within the software, ensuring consistency and efficiency in their maintenance management activities.

One of the key benefits of using Maintmaster is its ability to manage maintenance tasks and create fault reports on your machines. This will help organisations quickly identify and address problems with their equipment and facilities, reducing the impact of equipment breakdowns on their operations.

Additionally, Maintmaster provides organisations with a centralised platform for managing their maintenance management activities. This allows them to streamline their processes and improve efficiency, saving time and resources in the long run.

Calibration Management

Calibration management is a critical aspect of ensuring accurate and reliable measurements in various industries. To effectively manage calibrations, it is important to have clear instructions, records, certificates, and standards in place, as well as well-defined archiving protocols.

-

Calibration Instructions: Detailed calibration instructions are essential for ensuring that calibrations are performed correctly and consistently. These instructions should include step-by-step procedures for performing calibrations, as well as information on the necessary tools and equipment.

-

Calibration Records: Proper calibration records are necessary to document the results of calibrations and ensure that measurements are accurate and reliable. These records should include information on the instrument being calibrated, the date of the calibration, and the results of the calibration.

-

Calibration Certificates: Calibration certificates serve as a formal record of the calibration results and provide evidence that the instrument has been calibrated to a specific standard. These certificates should include information on the instrument, the date of the calibration, and the results of the calibration.

-

Calibration Standards: Calibration standards are essential for ensuring accurate and reliable calibrations. These standards provide a reference for the calibration of instruments and should be traceable to national or international standards.

-

Archiving Protocols: Effective archiving protocols are necessary for ensuring that calibration records and certificates are stored and easily accessible. These protocols should be well-defined and include information on how long records and certificates should be kept and how they should be stored.

In conclusion, by implementing clear instructions, records, certificates, standards, and archiving protocols, organisations will ensure the accuracy and reliability of their calibrations, improving the quality of their measurements and operations.

How Maintmaster will help

Maintmaster is a powerful tool that helps organisations effectively manage their calibration processes. By using Maintmaster, organisations will streamline their calibration management activities, ensuring that they are performed accurately and consistently.

-

Entering Measuring Equipment: By entering measuring equipment into Maintmaster as objects, organisations will keep track of all their equipment and easily manage calibrations. This helps to ensure that calibrations are performed on all necessary equipment, reducing the risk of incorrect measurements.

-

Recurring and Corrective Jobs: Maintmaster provides organisations with the ability to create recurring and corrective jobs for each calibration task. This ensures that calibrations are performed on a regular basis and that any issues with equipment are addressed promptly, improving the accuracy and reliability of measurements.

In conclusion, by using Maintmaster to manage their calibration processes, organisations will improve the efficiency and effectiveness of their calibration management activities. The ability to create recurring and corrective jobs, as well as enter measuring equipment as objects into the software, will help organisations ensure accurate and reliable calibrations, improving the quality of their measurements and operations.

Total Productive Maintenance

Proper maintenance management is essential for the smooth functioning of equipment and facilities. However, without involving operating staff in the maintenance process, problems will arise that negative impact operation. This highlights the importance of effective communication and the involvement of operating staff in maintenance management.

-

Total Productive Maintenance (TPM): TPM is a maintenance philosophy that involves all employees, including operating staff, in the maintenance process. By involving operating staff in TPM activities, organisations will improve the efficiency and effectiveness of their maintenance processes, ensuring that equipment is maintained properly and that problems are addressed promptly.

-

Reporting: Effective reporting is essential for ensuring that maintenance processes are performed accurately and that any problems are addressed promptly. By involving operating staff in the reporting process, organisations will ensure that all necessary information is captured and that any issues are addressed in a timely manner.

In conclusion, by involving operating staff in the maintenance process through TPM and effective reporting, organisations will improve the efficiency and effectiveness of their maintenance activities. This will help to ensure that equipment is maintained properly and that problems are addressed promptly, improving the overall quality of operations.

How Maintmaster will help

By using Maintmaster, organisations will improve communication and collaboration between maintenance and operating staff, ensuring that maintenance processes are performed accurately and effectively.

-

Inviting Production Staff: Maintmaster allows organisations to invite their production staff to the software, giving them access to the status of the machines they are working on. This helps to improve communication and collaboration between maintenance and operating staff, ensuring that maintenance processes are performed accurately and effectively.

-

Assigning Simple Maintenance Tasks: Maintmaster also provides organisations with the ability to assign simple maintenance tasks to their operating staff. This will help to improve the efficiency and effectiveness of maintenance activities, reducing the risk of equipment downtime and improving the quality of operations.

By using Maintmaster to involve operating staff in their maintenance management activities, organisations will improve communication and collaboration between maintenance and operating staff, ensuring that maintenance processes are performed accurately and effectively. The ability to invite production staff to the software and assign simple maintenance tasks will help organisations improve the efficiency and quality of their operations.

Document Management

Proper documentation is essential for ensuring that maintenance processes are performed accurately and that any problems are addressed promptly. However, without an effective document approval procedure and a clear revision status list, problems will arise that negative impact operation. This highlights the importance of having a clear and effective document approval procedure and a revision status list in maintenance management.

-

Document Approval Procedure: A clear and effective document approval procedure is essential for ensuring that maintenance documentation is accurate and up-to-date. This helps to reduce the risk of equipment downtime and improve the quality of operations.

-

Revision Status List: A clear revision status list is essential for ensuring that maintenance staff are aware of the most recent version of each document and that they are using the correct version when performing maintenance activities. This helps to ensure that maintenance processes are performed accurately and that any problems are addressed promptly.

In conclusion, by having a clear and effective document approval procedure and a revision status list in place, organisations will ensure that their maintenance documentation is accurate and up-to-date. This will help to reduce the risk of equipment downtime and improve the quality of operations.

How Maintmaster will help

Maintmaster provides an effective solution for organisations looking to manage their document approval procedures and revision status in maintenance management. With Maintmaster, organisations will ensure that their maintenance documentation is accurate and up-to-date, reducing the risk of equipment downtime and improving the quality of operations.

-

Storing Documents as Objects: Maintmaster allows organisations to store their maintenance documents as objects within the software. This helps to ensure that all documentation is centralised and easily accessible to maintenance staff.

-

Revision Creation with Jobs: Maintmaster provides organisations with the ability to create each revision of a document as a job within the software. This helps to ensure that each revision is properly recorded and that the revision status list is accurate and up-to-date.

-

Approval Structures: Maintmaster also provides organisations with the ability to set up approval structures for their maintenance documents. This helps to ensure that the document approval procedure is clear and effective, reducing the risk of errors and improving the quality of operations.

When using Maintmaster to manage document approval procedures and revision status, organisations will ensure that their maintenance documentation is accurate and up-to-date. The ability to store documents as objects, create revisions as jobs, and set up approval structures can help organisations reduce the risk of equipment downtime and improve the quality of operations.

Overall Equipment Effectiveness

Measuring overall equipment efficiency (OEE) and improving overall plant efficiency is essential for ensuring that equipment and facilities are functioning at their best. However, without a proper process in place, problems will arise that negatively impact efficiency. This highlights the importance of having a process in place for measuring OEE and improving overall plant efficiency.

-

Measure Overall Equipment Efficiency (OEE): Measuring OEE is essential for understanding the performance of individual pieces of equipment and identifying areas for improvement. This helps to ensure that equipment is functioning at its best and that any problems are addressed promptly.

-

Improve Overall Plant Efficiency: Improving overall plant efficiency is essential for ensuring that facilities are functioning at their best and that any problems are addressed promptly. This will be achieved by identifying common faults and addressing them promptly.

In conclusion, by having a process in place for measuring OEE and improving overall plant efficiency, organisations can ensure that their equipment and facilities are functioning at their best. This will help to reduce the risk of equipment downtime and improve the quality of operations.

How Maintmaster will help

using Maintmaster to track maintenance-related data, organisations will have a better understanding of the performance of their equipment and identify areas for improvement. This includes tracking downtime and fault incidences, which are critical factors in calculating OEE numbers. The OEE module in Maintmaster provides a comprehensive and straightforward solution for organisations looking to measure and improve their overall equipment efficiency. With accurate and up-to-date information, organisations will make informed decisions about maintenance and operations, ultimately leading to increased efficiency and productivity.

Maintmaster Audit handbook

Don't let the complexity of certification hold your business back. Use our comprehensive audit and certification guide and MaintMaster, the most flexible maintenance management software, to ensure your compliance with the most common certifications.

Enhance your maintenance department and ensure a successful future for your business.

Act now!

- 1. Why this handbook?

- 2. Management Systems - ISO 9001 & ISO 14001

- 3. Management Systems - ISO 45001

- 4. Management Systems - ISO 28000

- 5. Energy & Environment - ISO 50001 & ISO 14001

- 6. Automotive - IATF 16949

- 7. Food - FSC & BRC

- 8. Implementing Certifications with MaintMaster

- 9. Learn the basics of a CMMS