Chapter 3

Management Systems

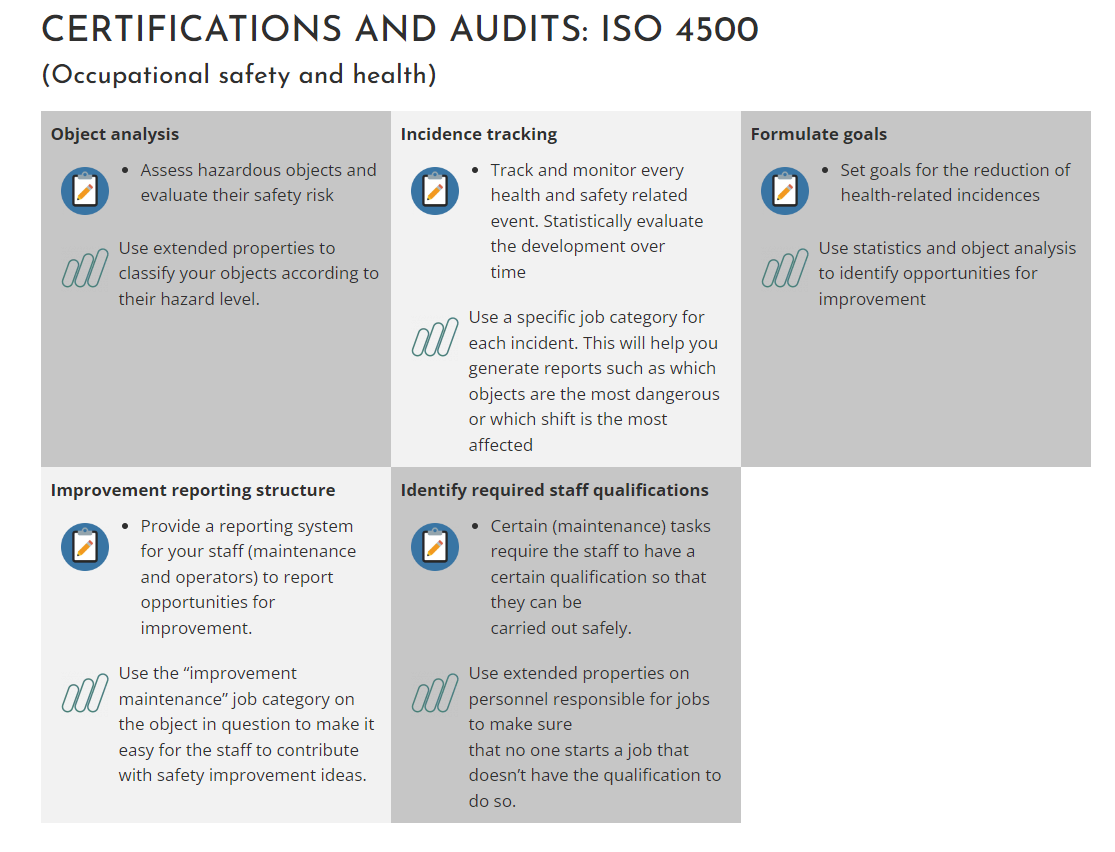

ISO 45001

Occupational safety and health

ISO 45001 is an international standard that provides guidelines for occupational health and safety management systems. It provides a framework for managing and reducing risks related to health and safety in the workplace, helping organisations to provide a safe and healthy working environment for their employees. By implementing and following ISO 45001, organisations can demonstrate their commitment to occupational health and safety and ensure that their employees are protected from workplace hazards. The certification process helps organisations to evaluate and improve their OH&S management systems and processes, and can help build trust with stakeholders and customers.

Object analysis

Object analysis is a critical aspect of occupational health and safety management. It involves the systematic evaluation of hazardous objects to assess their safety risk and identify potential hazards. This process helps ensure that the workplace is safe for employees and reduces the risk of accidents, injuries and other safety incidents. By conducting regular item analyses, companies can proactively address safety risks and promote a culture of safety in the workplace.

How Maintmaster will help

Maintmaster provides a solution for assessing hazardous items and assessing their safety risk by using advanced properties to classify these items according to their hazard level. This enables organisations to better understand the potential risks associated with their equipment and facilities and take appropriate action to mitigate these risks. With Maintmaster, organisations can ensure that their operations are safe and secure, protecting their people and assets.

Incidence tracking

Having backup plans in place is critical to ensuring the continuity of production processes, especially in the event of equipment failure. The criticality of an asset determines the level of backup plans required. For critical assets, backup plans should be comprehensive and include detailed procedures for restoring production quickly and effectively in the event of a failure.

On the other hand, for non-critical assets, back-up plans can be more basic, focusing on maintaining production with minimal disruption. The aim of contingency plans is to minimise the impact of equipment failure and ensure that production processes continue to run smoothly, regardless of unexpected events.

How Maintmaster will help

Maintmaster IoT sensors provide an effective solution for detecting deviations in production processes before they occur. By monitoring key parameters in real time, these sensors help to identify potential problems before they become critical, allowing companies to take proactive steps to mitigate risk and minimise downtime.

With Maintmaster IoT sensors, companies will have greater visibility and control over their production processes, ensuring they are always operating at optimum levels. If you're interested in learning more about the capabilities and benefits of Maintmaster IoT sensors, the Maintmaster sales team will be happy to help. They can tell you how and where these sensors can be used and how they can help you improve the efficiency and reliability of your production processes. Contact the Maintmaster sales team today to find out more.

Formulate goals

Setting targets for reducing health-related incidents is an important and challenging task that requires careful consideration and planning. It requires organisations to take a proactive approach to occupational health and safety management and to continually evaluate and improve their systems and processes.

This is a crucial step in reducing the risk of health-related incidents in the workplace and ensuring the well-being of employees. Implementing and following the guidelines is essential for organisations that are serious about addressing the issue of health-related incidents in the workplace.

How Maintmaster will help

Using statistics and objective analysis to identify opportunities for improvement is critical to reducing the risk of health-related incidents in the workplace. It helps organisations take a data-driven approach to health and safety management and prioritise their efforts where they will have the greatest impact.

To effectively collect and analyse health related incident data, organisations need a robust and effective tool to support their efforts. As Maintmaster CMMS is integrated with the European Maintenance Standard, this would be a perfect solution.

Improvement reporting structure

Creating an improved reporting structure is critical to identifying and addressing opportunities for improvement in the workplace. By providing a clear and effective reporting system for maintenance and operations staff, organisations can ensure that they are able to gather valuable insight and feedback from the people directly involved in their operations.

How Maintmaster will help

Improve asset safety with the 'Improvement Maintenance' job category in Maintmaster. To ensure that all employees have the opportunity to contribute to the continuous improvement of safety in the workplace, it is important to create a platform that makes it easy for them to share their ideas and suggestions.

This job category would allow employees to report any potential safety hazards or areas for improvement that they observe in the course of their work. By giving them a designated space to report these issues, organisations can ensure that all relevant information is captured and that employees feel empowered to contribute to improving workplace safety.

Identify required staff qualifications

To ensure that maintenance tasks are carried out safely and effectively, it is important to identify the required qualifications of the people who will be carrying out these tasks.

Each maintenance task has its own unique set of requirements and risks, and it is the responsibility of the organisation to ensure that the personnel carrying out these tasks have the necessary qualifications and skills to do so safely. This may include formal training and certification in specific areas, such as electrical safety or hazardous materials handling, or experience and expertise with specific types of equipment or systems.

How Maintmaster will help

In order to maintain a safe and efficient workplace, it is essential to ensure that only personnel with the necessary qualifications and skills start and complete tasks. This requires careful tracking of the personnel responsible for each task and the qualifications and certifications they hold.

This is achieved by using advanced properties on the personnel responsible for the jobs. This allows organisations to track the qualifications and certifications of their employees and ensure that no one starts a job they are not qualified to do. This helps to minimise the risk of accidents and incidents in the workplace and protects the health and safety of all employees.

Maintmaster Audit handbook

Don't let the complexity of certification hold your business back. Use our comprehensive audit and certification guide and MaintMaster, the most flexible maintenance management software, to ensure your compliance with the most common certifications.

Enhance your maintenance department and ensure a successful future for your business.

Act now!

- 1. Why this handbook?

- 2. Management Systems - ISO 9001 & ISO 14001

- 3. Management Systems - ISO 45001

- 4. Management Systems - ISO 28000

- 5. Energy & Environment - ISO 50001 & ISO 14001

- 6. Automotive - IATF 16949

- 7. Food - FSC & BRC

- 8. Implementing Certifications with MaintMaster

- 9. Learn the basics of a CMMS