Chapter 4

Management Systems

ISO 28000

Security in the supply chain

ISO 28000 is a certification and auditing standard for ensuring security in the supply chain, including provisions for security incidents, continuous improvement and risk assessment. Achieving ISO 28000 certification demonstrates a commitment to secure and reliable supply chain management.

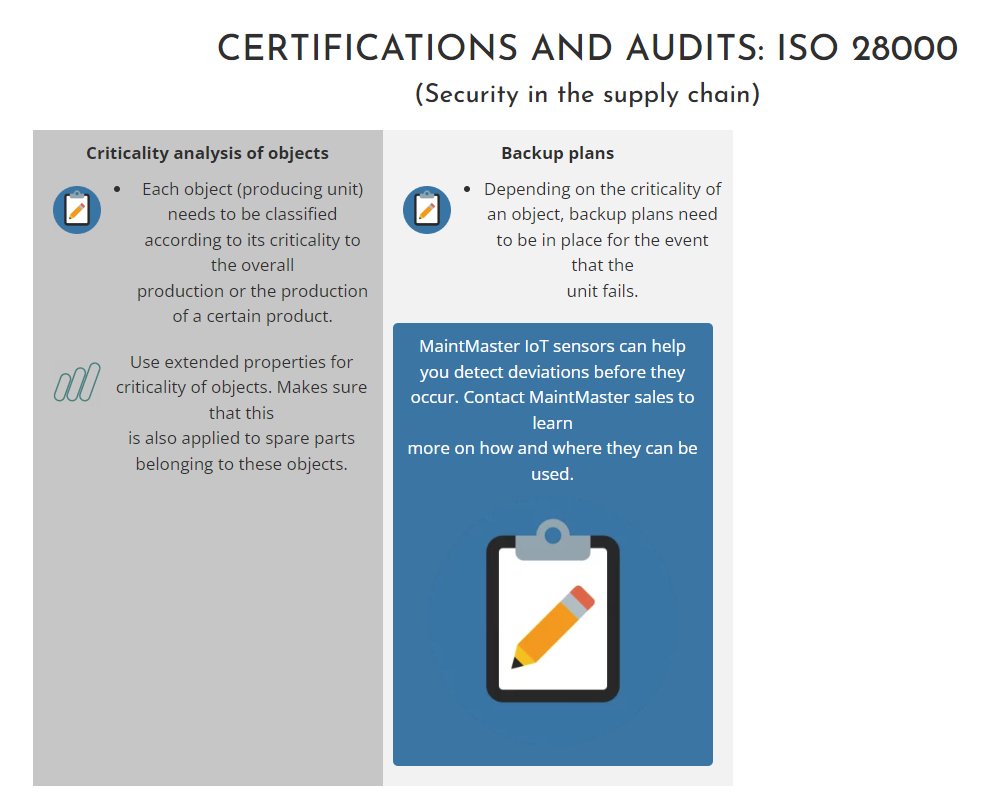

Criticality analysis of objects

Criticality analysis is a process of evaluating and classifying objects, such as production units, based on their level of importance to production as a whole or to the production of specific products.

This analysis helps to identify which items are critical to the production process and should receive priority attention in terms of resources, management and risk mitigation. By conducting a criticality analysis, companies can ensure that their production processes are optimised and that their resources are used effectively to achieve their objectives.

How Maintmaster will help

The use of advanced object criticality properties is an important step in ensuring the efficiency and reliability of production processes. By assigning criticality values to items and spare parts, organisations can prioritise their maintenance and replacement activities, ensuring that critical components are always in optimal condition.

This approach helps to minimise downtime and reduce the risk of production interruptions, which can be costly and affect overall production. By applying criticality analysis to both assets and spares, companies can ensure that their processes are optimised for maximum efficiency and that they are well prepared for any unexpected incidents or failures.

Backup plans

Having backup plans in place is critical to ensuring the continuity of production processes, especially in the event of equipment failure. The criticality of an asset determines the level of backup plans required. For critical assets, backup plans should be comprehensive and include detailed procedures for restoring production quickly and effectively in the event of a failure.

On the other hand, for non-critical assets, back-up plans can be more basic, focusing on maintaining production with minimal disruption. The aim of contingency plans is to minimise the impact of equipment failure and ensure that production processes continue to run smoothly, regardless of unexpected events.

How Maintmaster will help

Maintmaster IoT sensors provide an effective solution for detecting deviations in production processes before they occur. By monitoring key parameters in real time, these sensors help to identify potential problems before they become critical, allowing companies to take proactive steps to mitigate risk and minimise downtime.

With Maintmaster IoT sensors, companies will have greater visibility and control over their production processes, ensuring they are always operating at optimum levels. If you're interested in learning more about the capabilities and benefits of Maintmaster IoT sensors, the Maintmaster sales team will be happy to help. They can tell you how and where these sensors can be used and how they can help you improve the efficiency and reliability of your production processes. Contact the Maintmaster sales team today to find out more.

Maintmaster Audit handbook

Don't let the complexity of certification hold your business back. Use our comprehensive audit and certification guide and MaintMaster, the most flexible maintenance management software, to ensure your compliance with the most common certifications.

Enhance your maintenance department and ensure a successful future for your business.

Act now!

- 1. Why this handbook?

- 2. Management Systems - ISO 9001 & ISO 14001

- 3. Management Systems - ISO 45001

- 4. Management Systems - ISO 28000

- 5. Energy & Environment - ISO 50001 & ISO 14001

- 6. Automotive - IATF 16949

- 7. Food - FSC & BRC

- 8. Implementing Certifications with MaintMaster

- 9. Learn the basics of a CMMS