Chapter 7

Modification

According to the standard, modification is defined as: "The combination of all technical, administrative and managerial actions intended to change one or more functions of an item."

For maintenance, this means any action to improve product quality or speed. It also applies when we adapt equipment for a new product or packaging. These actions should be costed separately from the maintenance budget and are usually costed as an investment.

Comments

- Modification is not a maintenance action but refers to changing the required function of an item to a new one. Any changes made during a modification may affect the reliability characteristics of an item, but since the purpose is to change, the activity is still classified as a modification.

- Modification does not imply replacement with an equivalent unit.

- Modification of a unit may be a task for the maintenance organisation

Decision support data: Overhead costs or investment

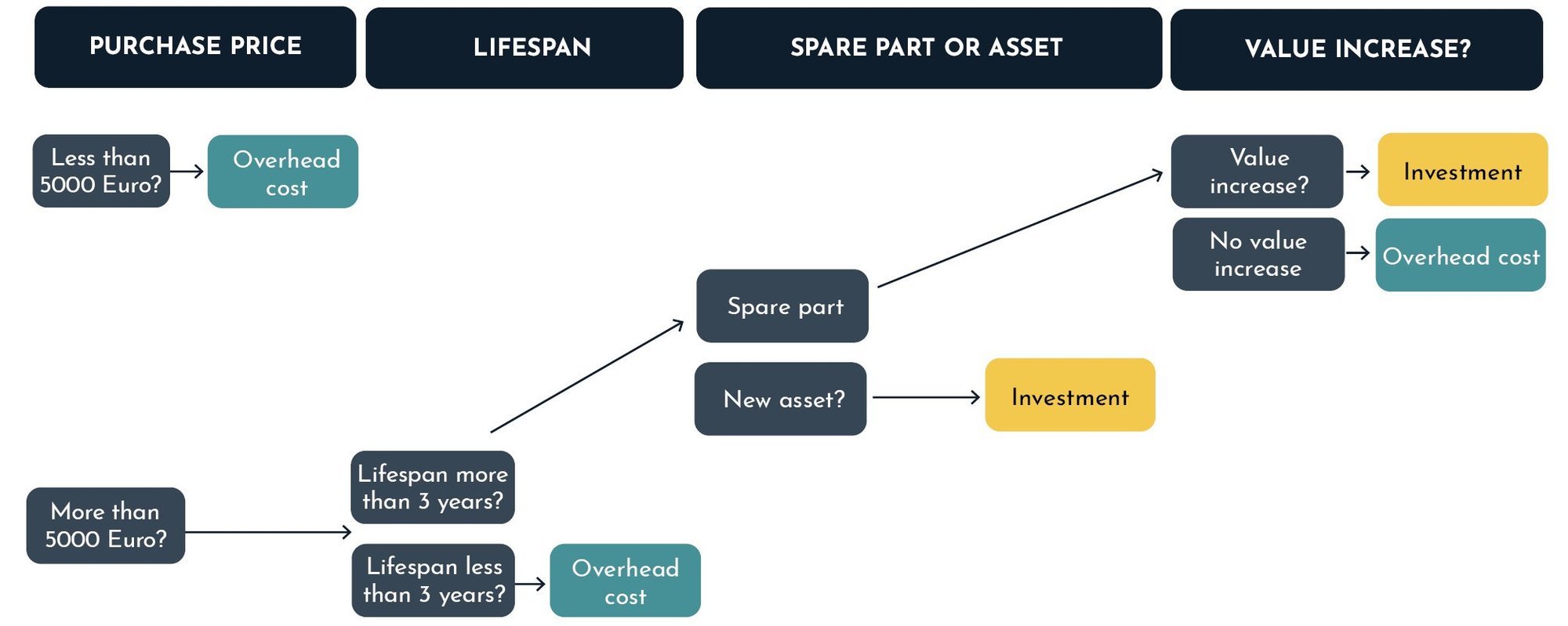

It can sometimes be difficult to determine whether a planned activity should be recognised as an investment (modification) or as an expense (improvement). The diagram below is intended to serve as an aid in determining when a similar issue arises. The economical levels in the model below are examples.

Maintmaster Maintenance Manual

This free manual can be used as a practical guide and support in the daily maintenance work and as part of the introductory material for newly employed personnel.

In this manual, you will learn:

How to create vision, strategy and policies for your maintenance team

How to build a maintenance team

Which KPIs to use and how to set them up

How to base your work on the EN Maintenance Standard

And a lot more…

- 1. Maintenance according to Euorpean standards

- 2. Maintenance Vision, Strategy & Policy

- 3. Maintenance standard

- 4. Preventive Maintenance

- 5. Corrective Maintenance

- 6. Improvement Maintenance

- 7. Modification

- 8. Case Management

- 9. Organisation

- 10. Finance

- 11. Goals & Key Performance Indiscators (KPIS)

- 12. Implementation in MaintMaster

- 13. Planning & Scheduling

- 14. Spare Parts Management

- 15. LEAN - 5S

- 16. Systematic Work Environment Management

- 17. Learn the basics of a CMMS