Chapter 9

Organisation

Business plan for maintenance

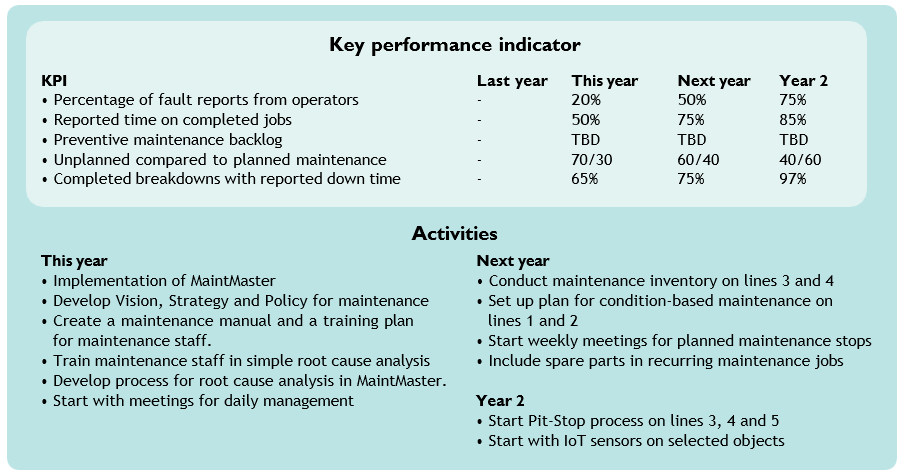

Your company normally has a business plan to describe the company's goals and visions and how this is to be implemented during a set period of time. This plan is then the basis for the maintenance business plan. It should specify activities supporting the company business plan, and also the development necessary of the maintenance organisation, everything to achieve the set goals of the company. Below is an example of how to specify the maintenance organisation's selected activities for the next three years. At the top of the business plan, we also show selected KPIs to be able to follow the development.

Roles and responsibilities ina "reliable" maintenance organisation

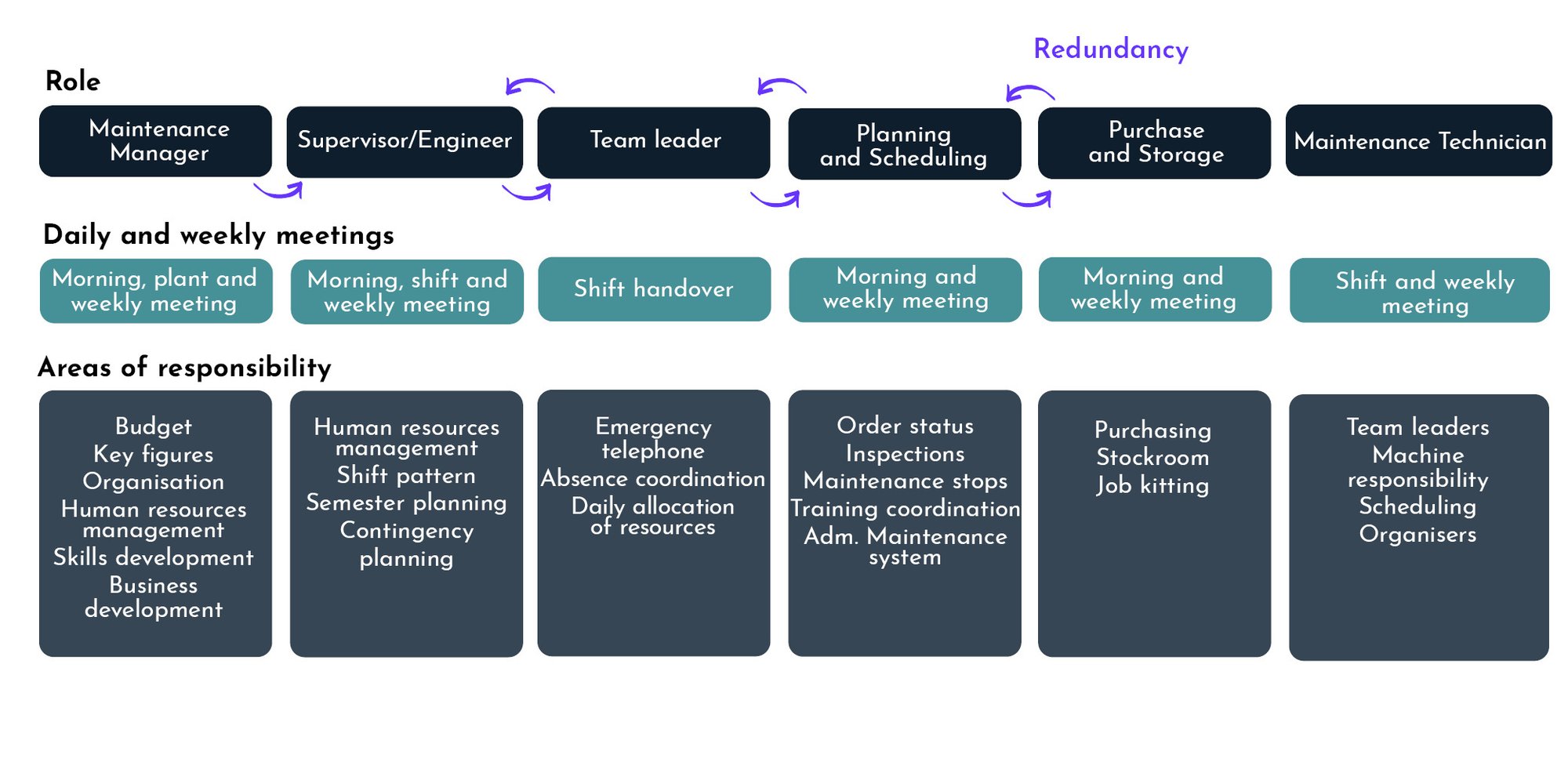

One of the most important goals of the maintenance organisation is to achieve high operational reliability through cost effective maintenance. An important part of this is that you have the right resources and an organisation supporting the chosen strategy to achieve your goals. Depending on the size of the organisation, you may need to combine different roles to make it work. However, it is important that it is clear which roles are responsible for different tasks and responsibilities in maintenance. Always strive for redundancy in the organisation to handle the daily work if someone is absent.

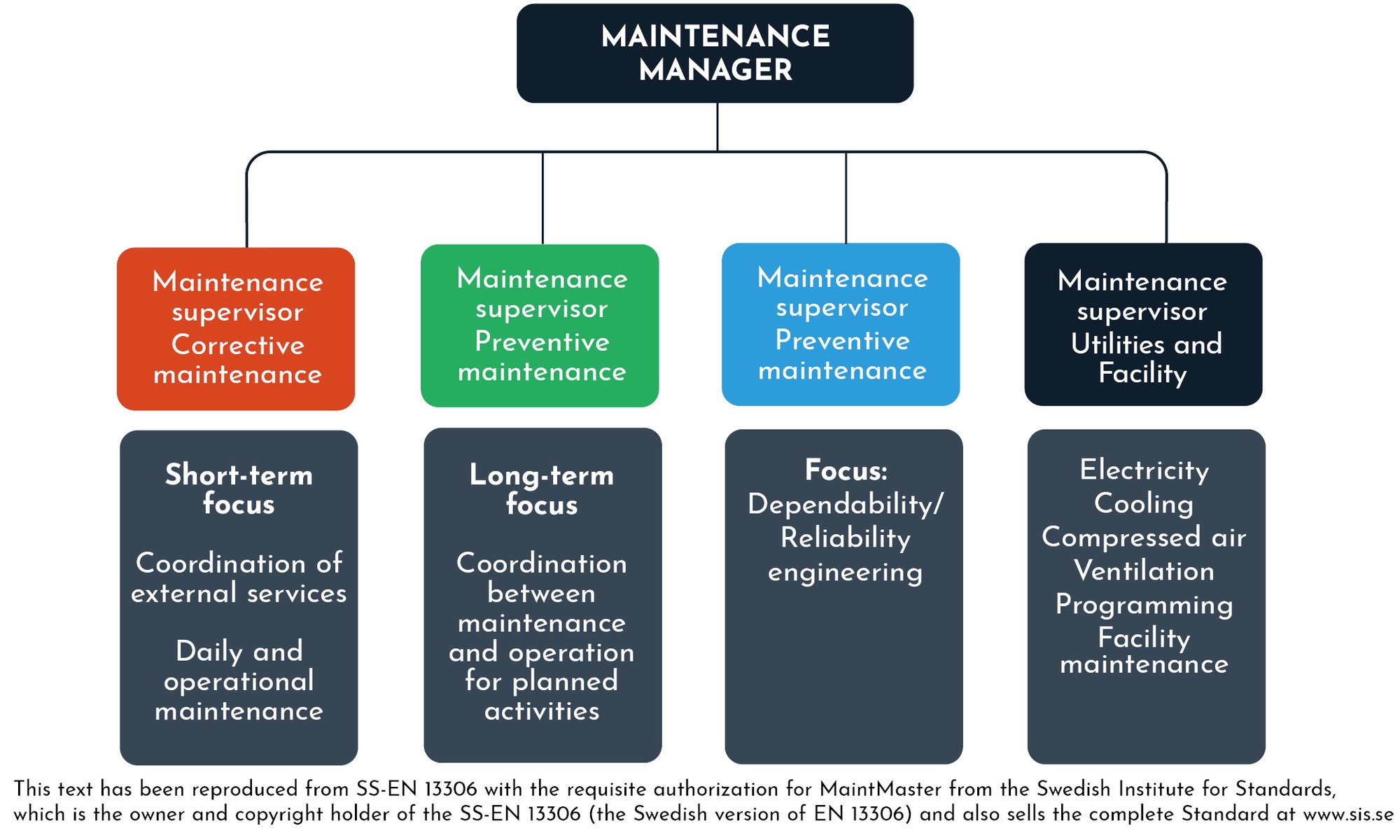

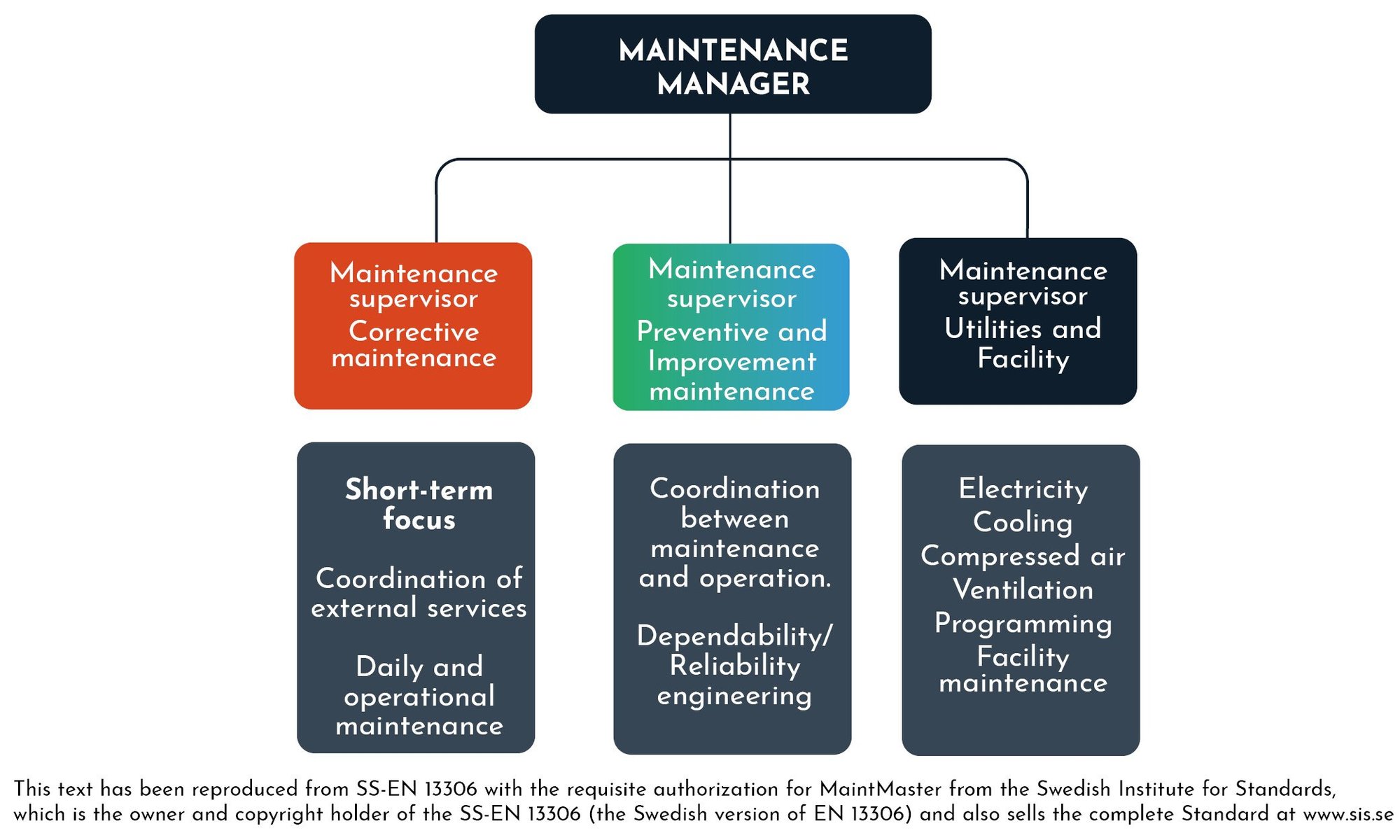

At MaintMaster, we are convinced that this is a very important part of building a reliable maintenance organisation. The picture below shows an example of allocating different responsibilities within maintenance. Another important part is that everyone in the organisation understands their role, not just management.

Focus on what your role needs to deliver. For example, as a manager or leader, you need to spend more time planning in the long term than helping out daily with a tool in your hand. Attendance is important, but evaluate how much of your working time is spent on day-to-day activities. Meetings are very important. Make sure that every meeting is meaningful. Everyone knows how easy it is to get tied up in meetings that have no meaning for you or your organisation.

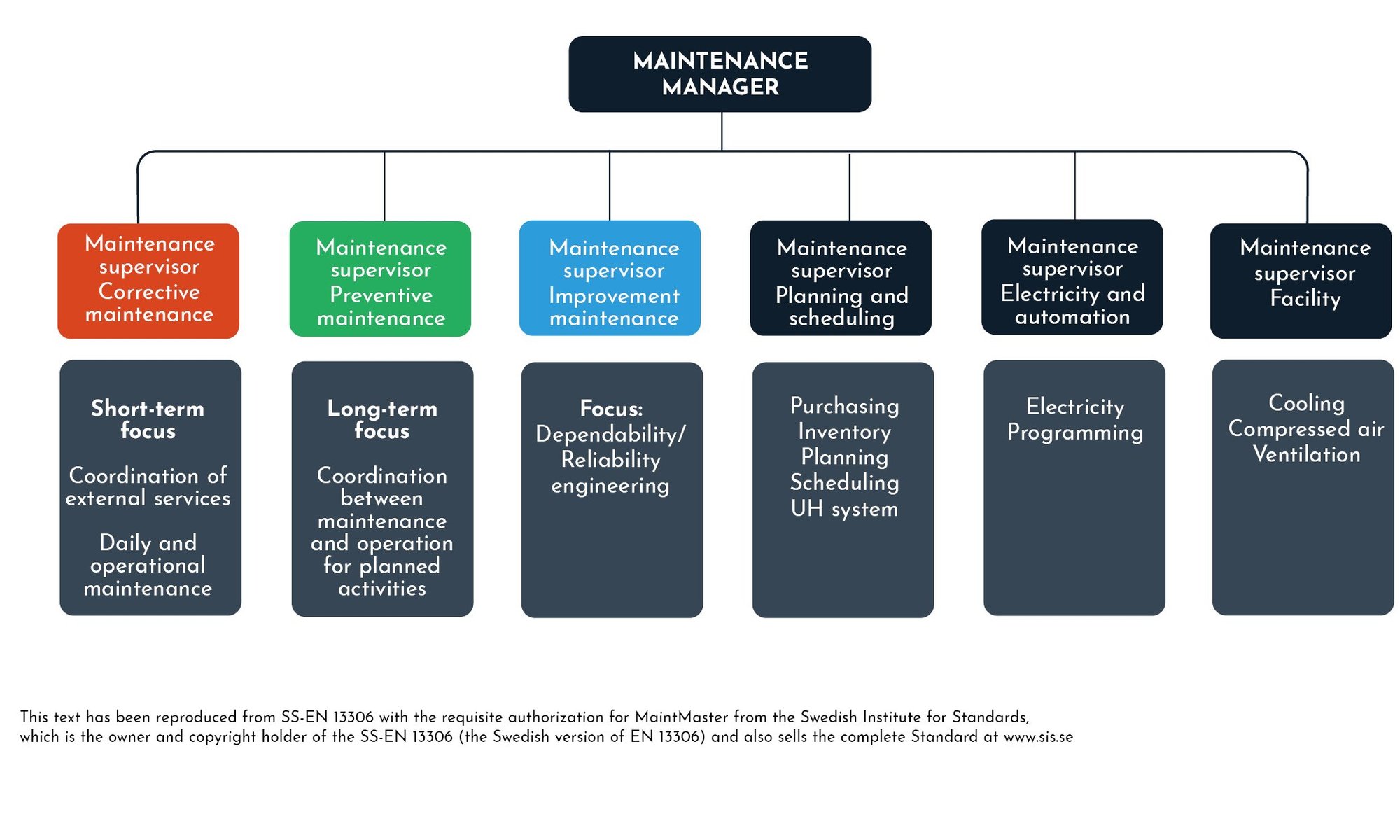

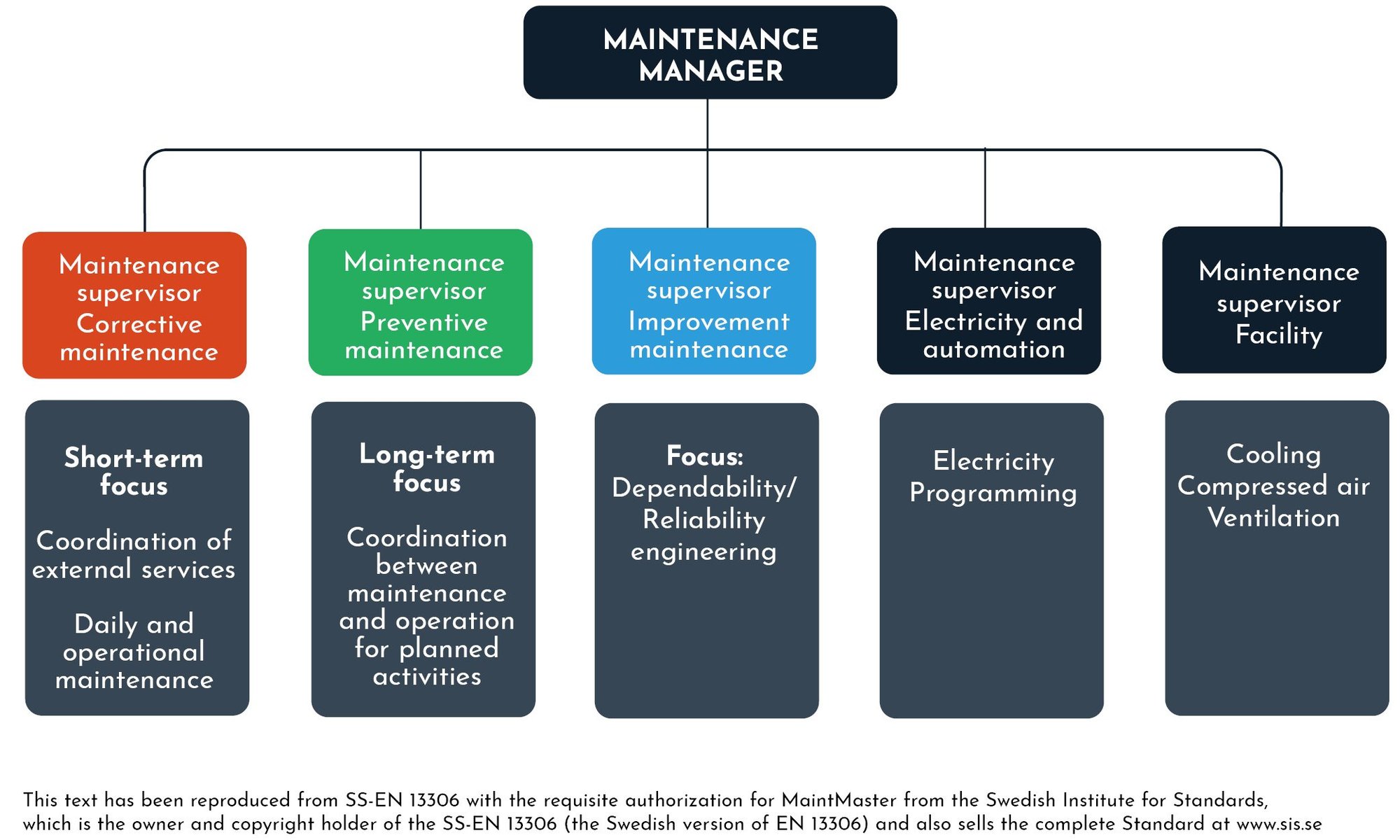

The maintenance organisation is responsible for executing, planning, managing and developing maintenance activities to ensure high reliability and availability of sites, machinery and equipment. The organisation can have different sizes, structures and competencies depending on the needs, resources and goals of the company, and different forms of cooperation with external factors, such as suppliers, contractors or consultants.

This may involve outsourcing some parts of the maintenance to other parties, either fully or partially. It may also involve the use of external expertise for specific tasks or projects. Whichever form of co-operation is chosen, it is important to have clear agreements, communication and follow-up between the parties involved.

There is no template for what an optimal maintenance organisation should look like; it depends on many factors such as the size, type, complexity, level of maturity and objectives of the business. However, it is important that the maintenance organisation carefully considers its maintenance strategy and adapts it to the needs and conditions of the Company business plan, and constantly strives to improve and develop its work.

A well functioning maintenance organisation is an important factor in achieving high operational reliability and availability, as well as contributing to the profitability and competitiveness of the business.

The following roles are examples of commonly used roles in a maintenance organisation.

Maintenance manager

Has overall responsibility for the maintenance management and its performance. The maintenance manager leads and manages the maintenance organisation in accordance with the company's vision, strategy and policy. The Maintenance Manager is also responsible for monitoring and reporting maintenance KPIs, budget and costs.

Maintenance supervisor

Leads and allocates tasks to technicians. May also provide support and assistance to various roles within the maintenance organisation. Supervisors usually also have personnel responsibilities for maintenance technicians.

Maintenance planner

Plans and coordinates maintenance work in co-operation with production, suppliers and maintenance staff. The maintenance planner is responsible for optimising the use of resources, minimising downtime and maximising maintenance efficiency. The maintenance planner is also responsible for documenting and archiving maintenance information in a maintenance system.

Maintenance technician

Carries out the actual maintenance work on the plant, machinery or equipment. The maintenance technician may have different specialisations, such as mechanical, electrical, automation or instrumentation. The maintenance technician is responsible for following the planned maintenance activities, reporting deviations and faults, and suggesting improvements.

Maintenance engineer

Has technical skills and knowledge in one or more areas of maintenance. The maintenance engineer supports and guides the maintenance staff in technical matters, analyses the causes of faults and malfunctions, and develops and implements solutions to prevent or correct faults. The maintenance engineer is also responsible for evaluating and updating maintenance plans, instructions and procedures.

Professional maintenance

Efficient maintenance is about value-creating maintenance from a preventive, planned and improvement perspective, where work that requires immediate corrective action is seen as a quality deficiency, and measures are taken to reduce the risk of the event occurring again. An essential part of ensuring that professional maintenance tasks is that the activities are coordinated with the work carried out by operational staff.

Professional maintenance is goal-oriented maintenance that constantly aims at improving operational reliability based on the needs of production by measuring and directing operations toward results. This is created by standardising how improvement activities, target management and result measurement are carried out, and by building in continuous optimisation of existing maintenance plans and processes.

- Goal-oriented maintenance and monitoring using key performance indicators.

- Budget work

- Standardised approach

- Corrective and preventive maintenance

- Planning and scheduling of maintenance activities

- Maintenance strategy

- Analysis (6-sigma, FMEA, SPL, Root Cause Analysis)

- Skills development

- Vibration and oil analyses

- Thermography

- Spare parts management

- Documentation

- LCC (Life Cycle Cost)

Maintenance organisation, based on EN 13306

Approximate organisation (100+ people)

Maintenance organisation, based on EN 13306

Approximate organisation (70-100 persons)

Maintenance organisation, based on EN 13306

Approximate organisation (30-70 people)

Maintenance organisation, based on EN 13306

Approximate organisation (15-30 people)

Maintmaster Maintenance Manual

This free manual can be used as a practical guide and support in the daily maintenance work and as part of the introductory material for newly employed personnel.

In this manual, you will learn:

How to create vision, strategy and policies for your maintenance team

How to build a maintenance team

Which KPIs to use and how to set them up

How to base your work on the EN Maintenance Standard

And a lot more…

- 1. Maintenance according to Euorpean standards

- 2. Maintenance Vision, Strategy & Policy

- 3. Maintenance standard

- 4. Preventive Maintenance

- 5. Corrective Maintenance

- 6. Improvement Maintenance

- 7. Modification

- 8. Case Management

- 9. Organisation

- 10. Finance

- 11. Goals & Key Performance Indiscators (KPIS)

- 12. Implementation in MaintMaster

- 13. Planning & Scheduling

- 14. Spare Parts Management

- 15. LEAN - 5S

- 16. Systematic Work Environment Management

- 17. Learn the basics of a CMMS