Chapter 13

Planning & Scheduling

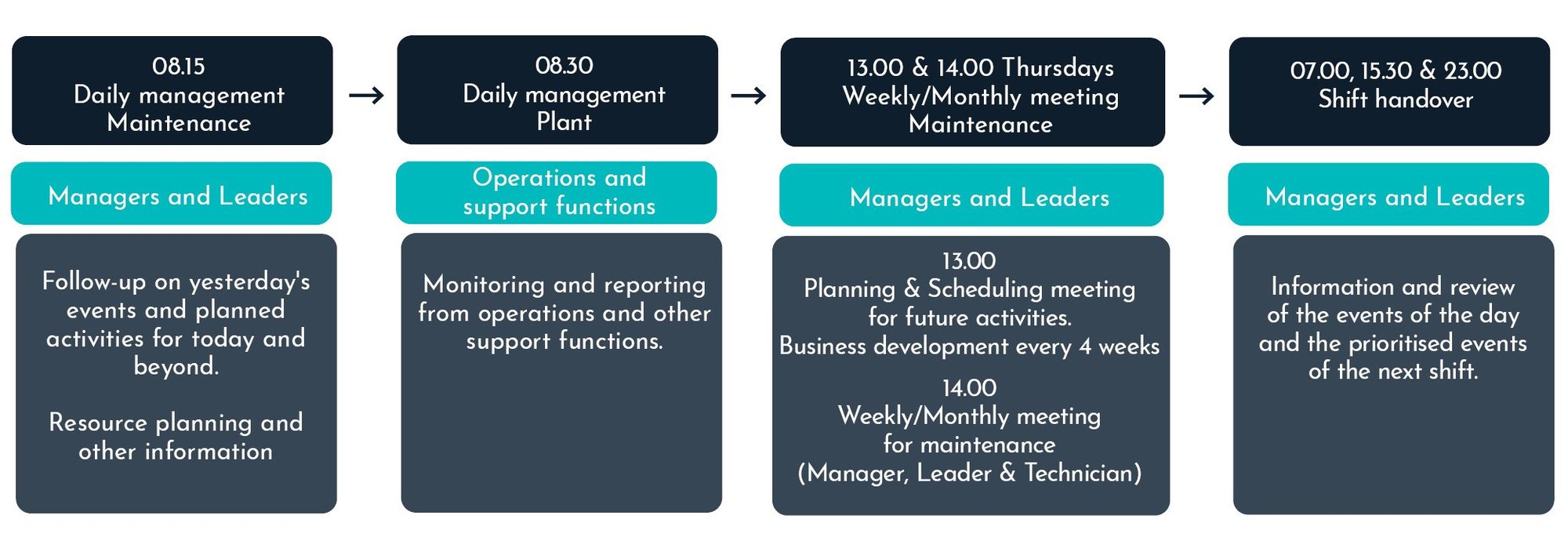

Follow-up of past events, and daily management of planned activities or newly emerged problems are important parts of the maintenance organisation's everyday life in order to maintain a functioning dialogue between different teams. Establish an agenda for each meeting and think about who should attend each meeting. Feel free to use a white board or a summary page with selections in MaintMaster CMMS to visualise which activities are ongoing or recently completed. Below is an example of a meeting structure that not only includes daily management, but more a basic planning for several different recurring meetings in a maintenance organisation. If you do not have a meeting structure in place, a tip is to start on a small scale with a morning meeting every day and then develop the process.

Planning and scheduling, maintenance activities

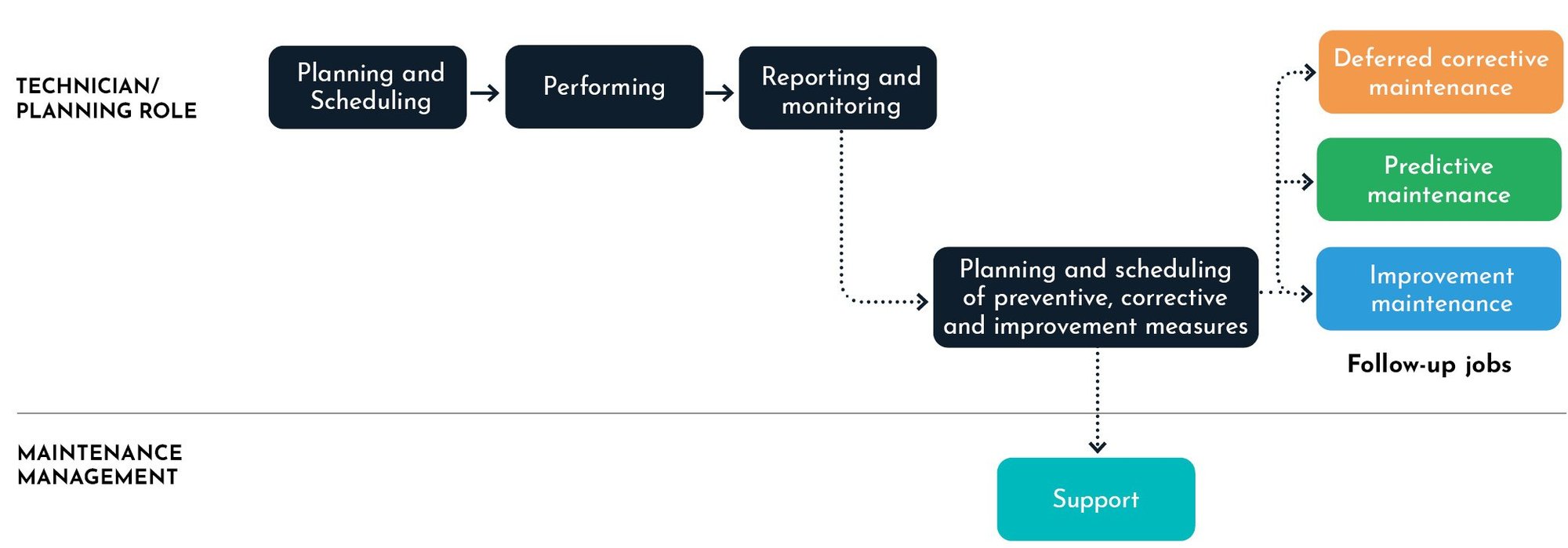

It is very important that preventive maintenance activities are well prepared in order to ensure quality efficiency and a safe work environment. This includes spare part needs, time and other necessary resources.

Some of the steps in the preparation process are:

- Registration and updating of asset records including picture navigation in the maintenance system.

- Decision and recording of spare parts to be stored, and linking them to objects in the maintenance system.

- Assesing the need for spare parts, and time consumption for recurring maintenance activities.

- Develop/update instructions for preventive maintenance.

- Labelling assets in the form of inventory numbers and lubrication points, etc.

Maintmaster Maintenance Manual

This free manual can be used as a practical guide and support in the daily maintenance work and as part of the introductory material for newly employed personnel.

In this manual, you will learn:

How to create vision, strategy and policies for your maintenance team

How to build a maintenance team

Which KPIs to use and how to set them up

How to base your work on the EN Maintenance Standard

And a lot more…

- 1. Maintenance according to Euorpean standards

- 2. Maintenance Vision, Strategy & Policy

- 3. Maintenance standard

- 4. Preventive Maintenance

- 5. Corrective Maintenance

- 6. Improvement Maintenance

- 7. Modification

- 8. Case Management

- 9. Organisation

- 10. Finance

- 11. Goals & Key Performance Indiscators (KPIS)

- 12. Implementation in MaintMaster

- 13. Planning & Scheduling

- 14. Spare Parts Management

- 15. LEAN - 5S

- 16. Systematic Work Environment Management

- 17. Learn the basics of a CMMS