Chapter 15

Lean - 5S

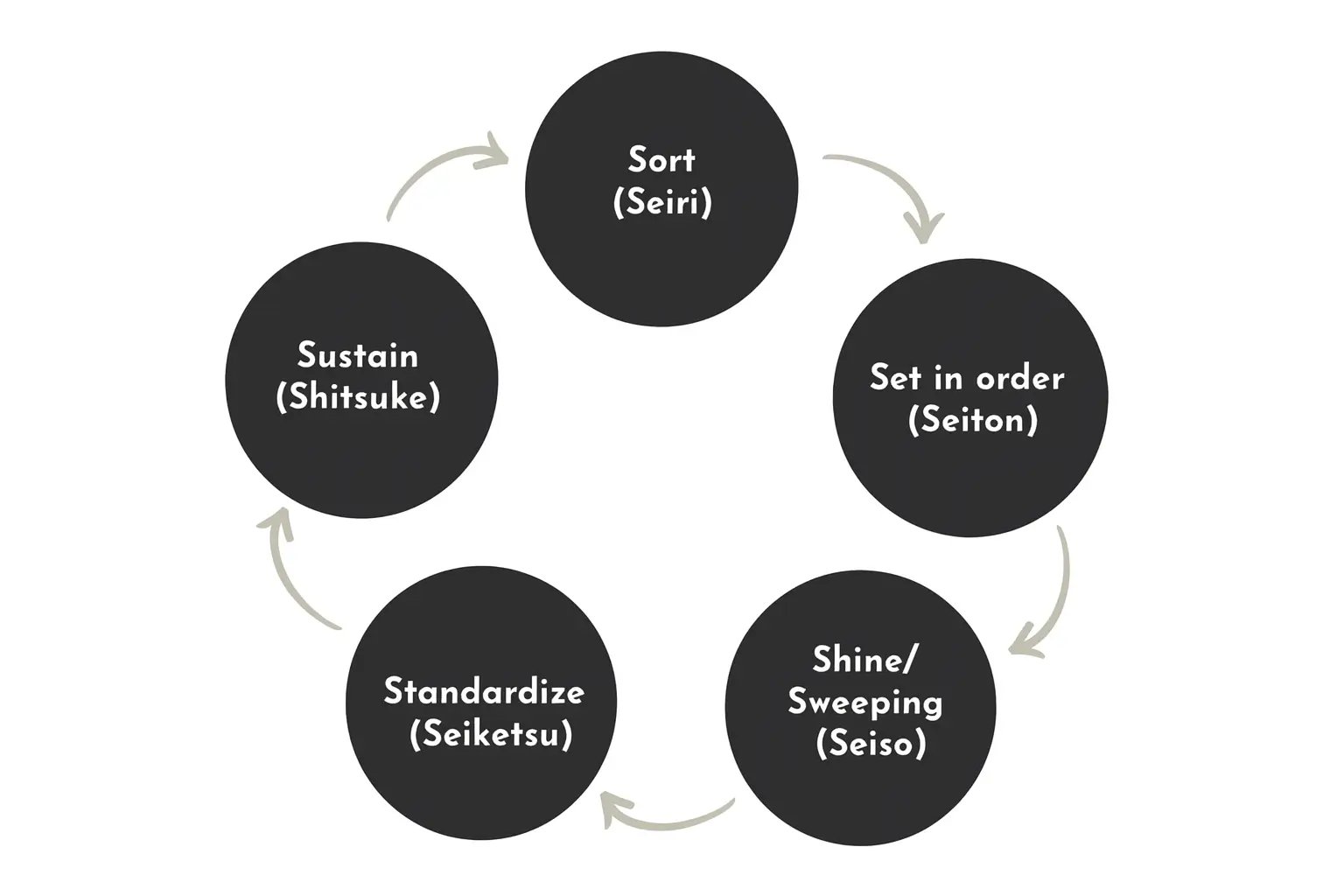

5S is a method for creating and maintaining an efficient, safe and orderly workplace. 5S can be introduced equally well in an office as in production, and is based on everyone's participation. 5S comes from five Japanese words, which have been translated into English, see explanation below.

A well-organised workplace makes work easier and significantly reduces the risk of injury. It also increases opportunities for better maintenance and reduces waste such as long changeover times and rejects. Above all, it makes for a more pleasant workplace and a more stable processes.

Maintmaster Maintenance Manual

This free manual can be used as a practical guide and support in the daily maintenance work and as part of the introductory material for newly employed personnel.

In this manual, you will learn:

How to create vision, strategy and policies for your maintenance team

How to build a maintenance team

Which KPIs to use and how to set them up

How to base your work on the EN Maintenance Standard

And a lot more…

- 1. Maintenance according to Euorpean standards

- 2. Maintenance Vision, Strategy & Policy

- 3. Maintenance standard

- 4. Preventive Maintenance

- 5. Corrective Maintenance

- 6. Improvement Maintenance

- 7. Modification

- 8. Case Management

- 9. Organisation

- 10. Finance

- 11. Goals & Key Performance Indiscators (KPIS)

- 12. Implementation in MaintMaster

- 13. Planning & Scheduling

- 14. Spare Parts Management

- 15. LEAN - 5S

- 16. Systematic Work Environment Management

- 17. Learn the basics of a CMMS