Chapter 14

Spare parts management

Spare parts management is about how spare parts should be systematised and structured to enable efficient inventory management that will lead to increased operational reliability and reduced tied-up capital.

When maintenance is performed, it often involves some form of material consumption. A breakdown often causes major problems and can be further worsen if spare parts are not available.

Without access to adequate spare parts, there is a risk of downtime, which can lead to lower quality outcomes, environmentally hazardous emissions and safety risks to personnel. One reason can be that it is often difficult to plan the consumption of spare parts as they have a varying demand. This is usually contradicted by building up an inventory of a large number of spare parts, which then often leads to a large amount of capital being tied up. It is therefore important to have a good system for storing and managing parts. This reduces the risk of unplanned downtime and simplifies the maintenance of the equipment. The aim of spare parts management is to minimise the total cost of ownership.

The total cost includes costs for storage, administration and various forms of shortage costs.

-

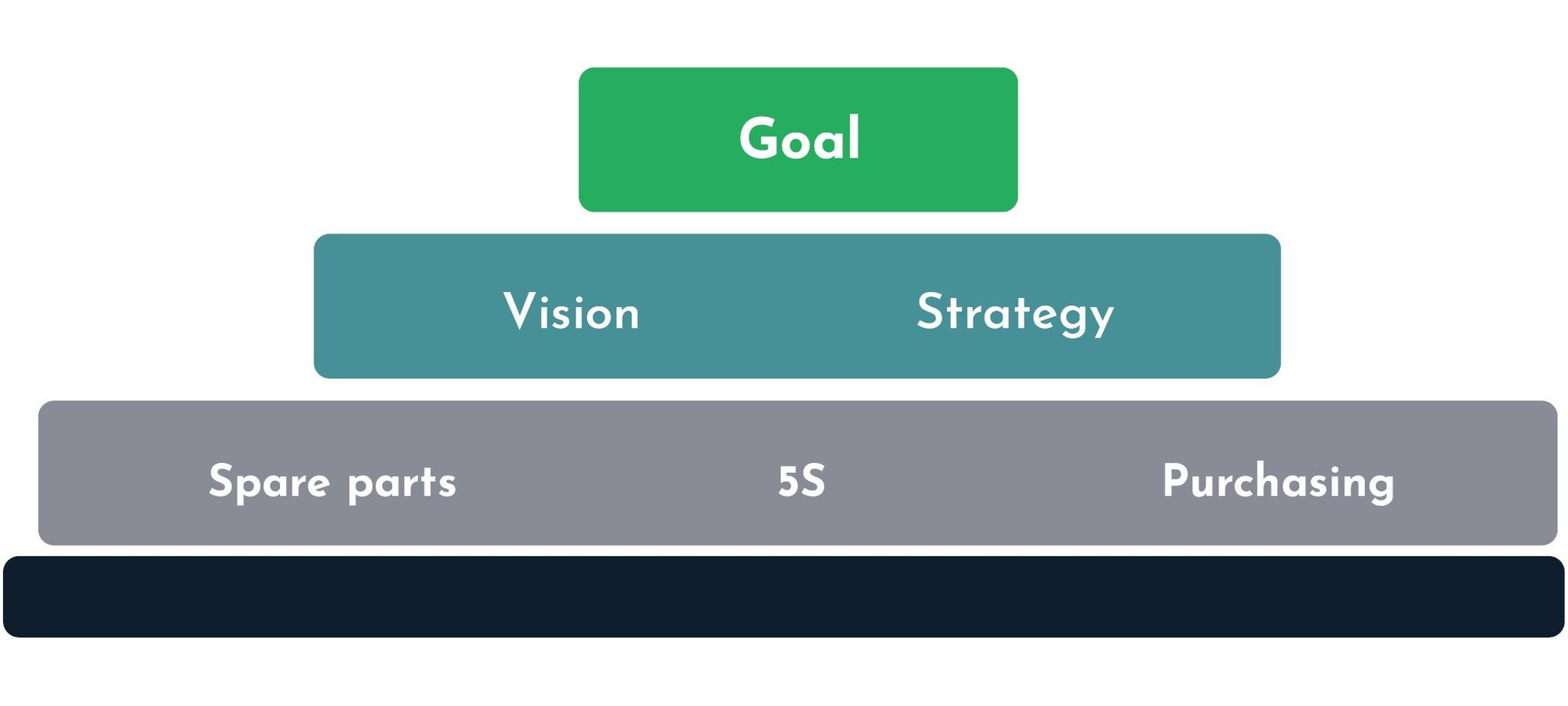

An Example of Spare Parts Management: Vision

• We will achieve a cost-effective spare parts handling together by combining methods, systems and staff effort.

-

• We have clear and concrete key figures that reflect our success in implementing working methods and costs in the stockroom.

• Spare parts management is a strong contributor to increased reliability in production.

- • We work in a structured manner and have good order and tidiness in all storage areas, where the labelling of spare parts is also clear and functional.

Spare parts management: Strategy

-

An Example of Spare Parts Management: Strategy

• Our spare part strategy is based on secure access to the right spare parts at the right time. Not all spare parts always.

-

• Spare parts are registered and linked to objects in the maintenance system by technicians. Consumable and insurance spare parts withdrawals are recorded directly to jobs in the maintenance system.

• To optimise inventory, we conduct needs assessments and classify spare parts to determine whether they should be kept in stock or procured when needed.

Objectives and key performance indicators for spare parts management

The aim for spare parts management is to keep the total cost of maintaining spare parts as low as possible, without compromising operational safety in any way.

High operational reliability requires that spare parts are available, or that the delivery time is as short as necessary. When faults do occur, it is important to find and rectify them as quickly as possible. The total cost includes costs for inventory, administration and various forms of shortage costs.

Some examples of KPIs we can use to measure Spare Parts Management:

- Inventory value and quantity.

- Number of unplanned purchase orders.

- The value of discarded material.

- Total cost (storage cost + shortage cost).

- Downtime (Depending on lack of spare part).

- Cost for storaging.

- Turnover rates (Excluding insurance spare parts).

- Inventory value / Insurance value of the production equipment.

Spare parts management

Assessing the need for spare parts

Maintenance activities often imply a need for replacement parts to be available in the stockroom. Therefore, to avoid unnecessary production downtime caused by long lead times, selected spare parts should be kept in stock. Spare parts not kept in stock should also be registered and linked to objects to reduce lead times when ordering. For recurring maintenance linked to appropriate objects, activities such as predetermined maintenance, spare parts should be ordered for the planned event instead of being kept in stock. Costs for storaging should be weighed against costs arising from shortages, but there are several other parameters to take into account in order to make a proper needs assessment, for instance material prone to ageing.

Examples of data for needs assessement:

- Consumption statistics.

- Supplier integration.

- Commitment from maintenance technicians and management.

- Classification of spare parts.

Classification of spare parts

To make it easier to optimise the stock, the spare parts could be divided into the following classes:

Consumables

- Items that cannot be considered as a spare part and may have a high consumption rate or low value.

Consumable spare parts

- Standard items such as sensors, cylinders and valves that can be used on several types of equipment, often with a lower value and a short lead time.

Insurance spare parts

- Spare parts that are kept in stock to avoid long and costly downtime. These can be expensive and often have a long lead time.

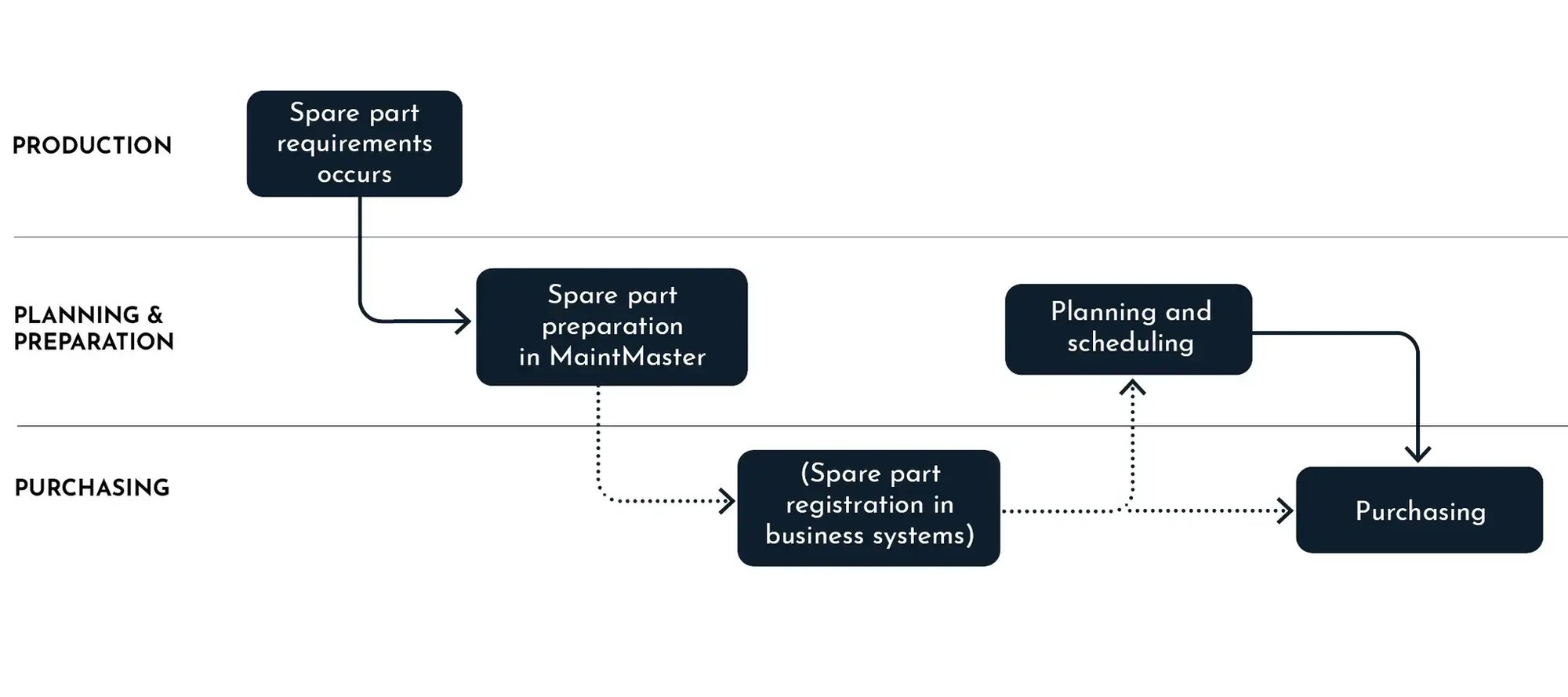

Spare part preparation and registration

The process map below shows the responsibilities and procedures for registering and purchasing spare parts in a normal situation. The scheduler or technician is responsible for ensuring that spare parts preparation is carried out for the line or equipment within their given area of responsibility. Support for this work may be called upon from maintenance management.

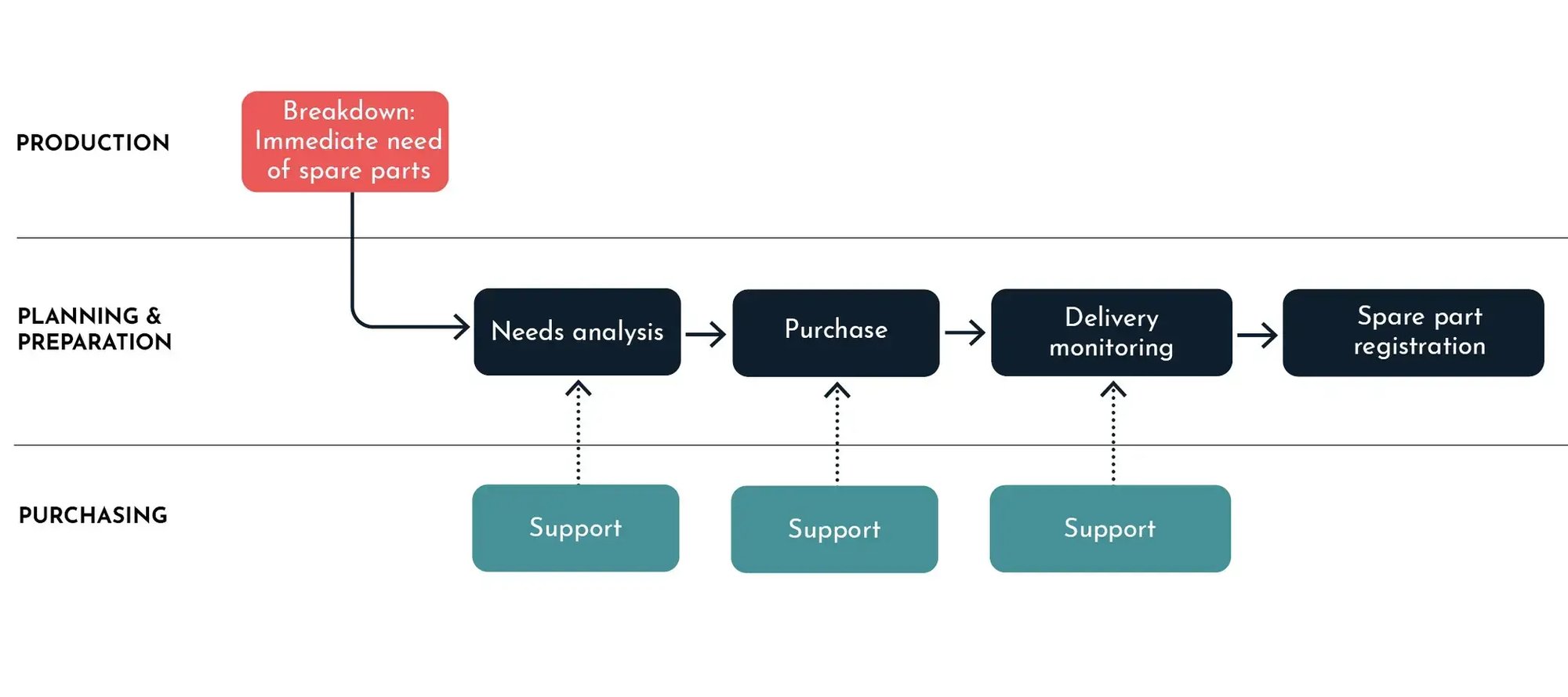

Immediate spare part need (non-stock item)

The process map below shows the responsibilities and procedures for registering and purchasing spare parts in case of a breakdown. The responsibility for an emergency purchase lies with the maintenance or department manager. Fact finding and ordering is delegated to the maintenance technician who can invoke the support of the maintenance management.

Maintmaster Maintenance Manual

This free manual can be used as a practical guide and support in the daily maintenance work and as part of the introductory material for newly employed personnel.

In this manual, you will learn:

How to create vision, strategy and policies for your maintenance team

How to build a maintenance team

Which KPIs to use and how to set them up

How to base your work on the EN Maintenance Standard

And a lot more…

- 1. Maintenance according to Euorpean standards

- 2. Maintenance Vision, Strategy & Policy

- 3. Maintenance standard

- 4. Preventive Maintenance

- 5. Corrective Maintenance

- 6. Improvement Maintenance

- 7. Modification

- 8. Case Management

- 9. Organisation

- 10. Finance

- 11. Goals & Key Performance Indiscators (KPIS)

- 12. Implementation in MaintMaster

- 13. Planning & Scheduling

- 14. Spare Parts Management

- 15. LEAN - 5S

- 16. Systematic Work Environment Management

- 17. Learn the basics of a CMMS