Chapter 11

Goals & Key Performance Indicators (KPIs)

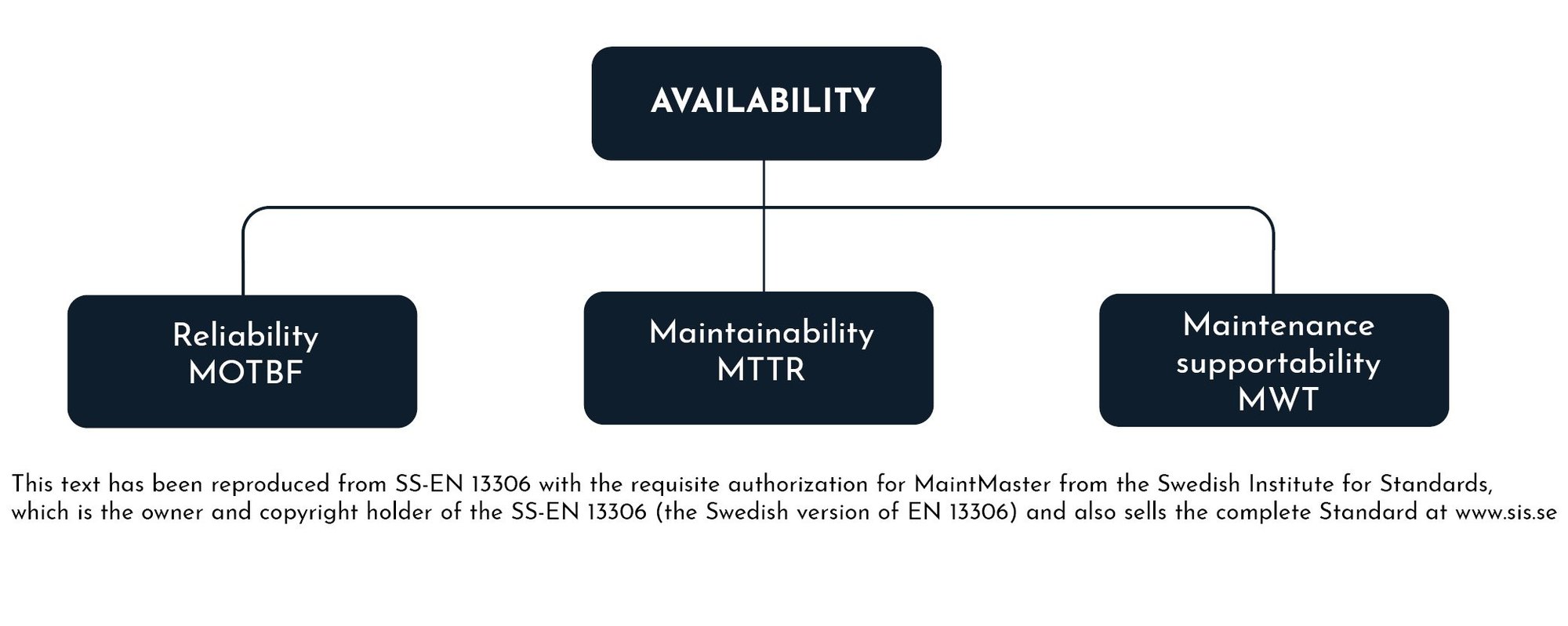

The maintenance organisations must always strive to improve operational and personal safety, which in turn has positive effects on availability. Operational safety depends on the combined characteristics of reliability, maintainability and maintenance supportability. These can be measured according to the following metrics:

Example of metrics

- Relation between planned and unplanned maintenance activities.

- Maintenance cost divided by production volume or number of units produced.

- Number of stops per machine or line.

- Downtime per object.

- MOTBF: Mean Operating Time Between Failures.

- MTTR: Mean Time To Restore.

- MMDT: Mean Maintenance Down Time (MMDT).

- MWT: Mean Waiting Time.

High operational reliability provides:

- • Lower maintenance costs

• Higher profitability

• More stable production

• Less loss of quality

• Lower energy costs

• Improving the working environment

• More time for improvements

KPIs:

EN 15341 - Maintenance Key Performance Indicators

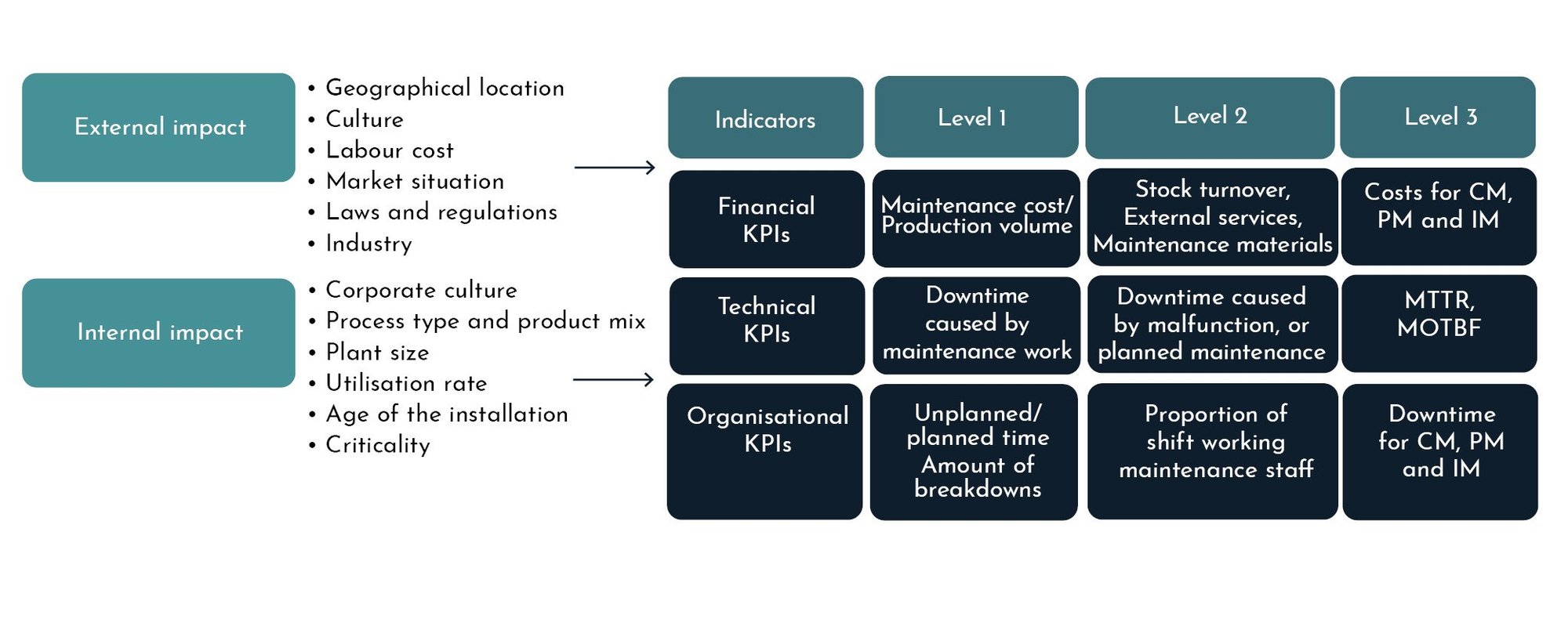

To effectively manage maintenance activities, it is important to measure what we do, how much and how well we do it. To do this, you need to identify a number of metrics, these are often referred to as key performance indicators (KPIs). The image below shows some examples from the standard, which contains pre-defined KPIs divided into 3 categories; financial, technical and organisational indicators. Choose an overall KPI from each category that adds value to the maintenance operation over time and that all staff can relate to.

Goals & KPIs: Dependability

According to European Standard, dependability is defined as: Dependability includes availability, safety, durability, economics, and their influencing factors (reliability, maintainability, Maintenance supportability, conditions of use and operators influence).

Availibility

According to European Standard availability defines as: The ability of a unit to perform the required function under specified conditions at a given time or within a set time interval, provided that the required support functions are available.

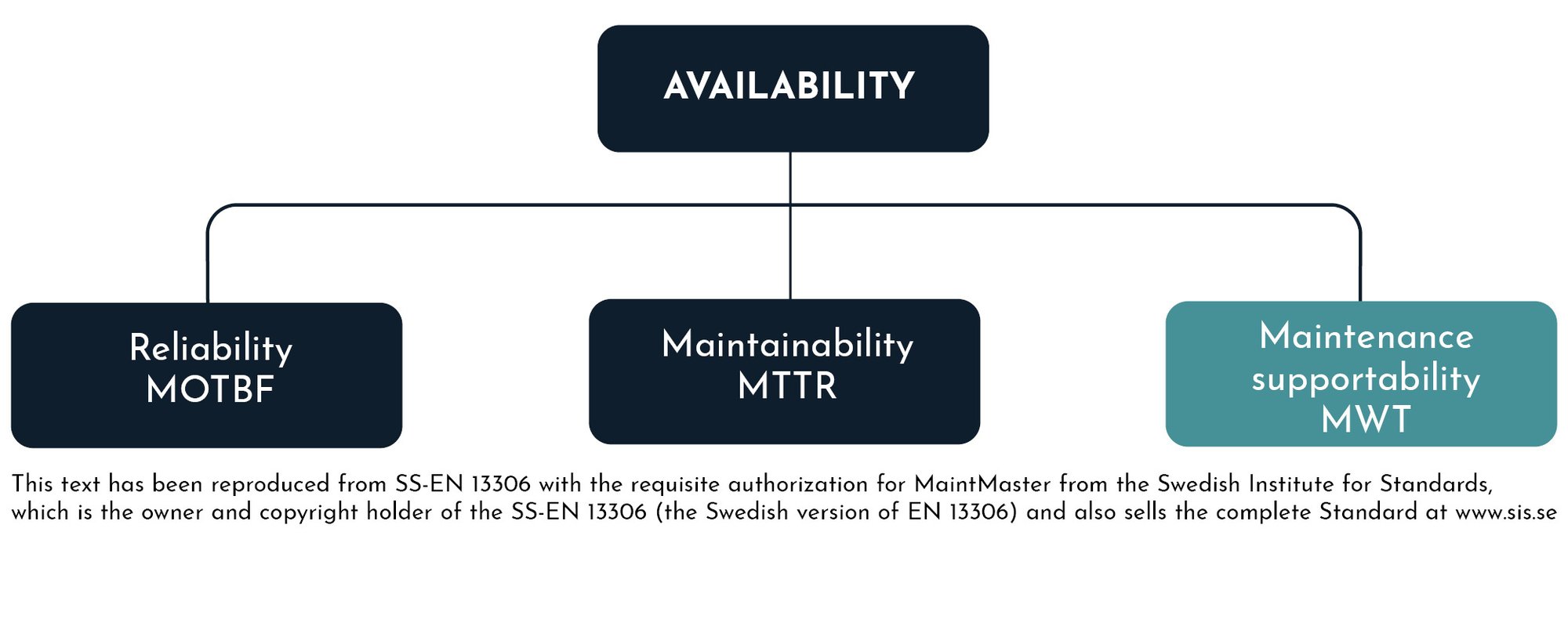

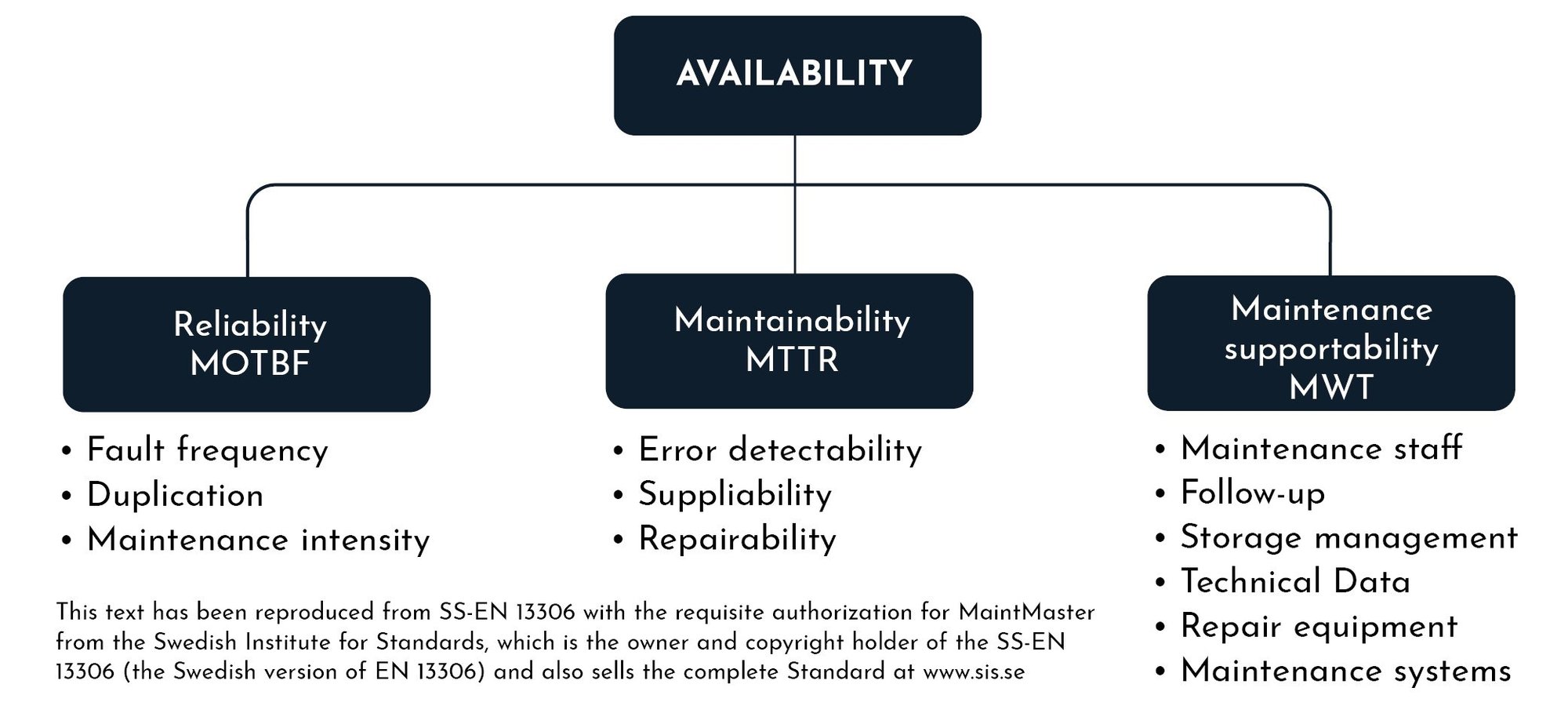

Note: Availability depends on the combined characteristics of reliability, maintainability, and maintenance supportability.

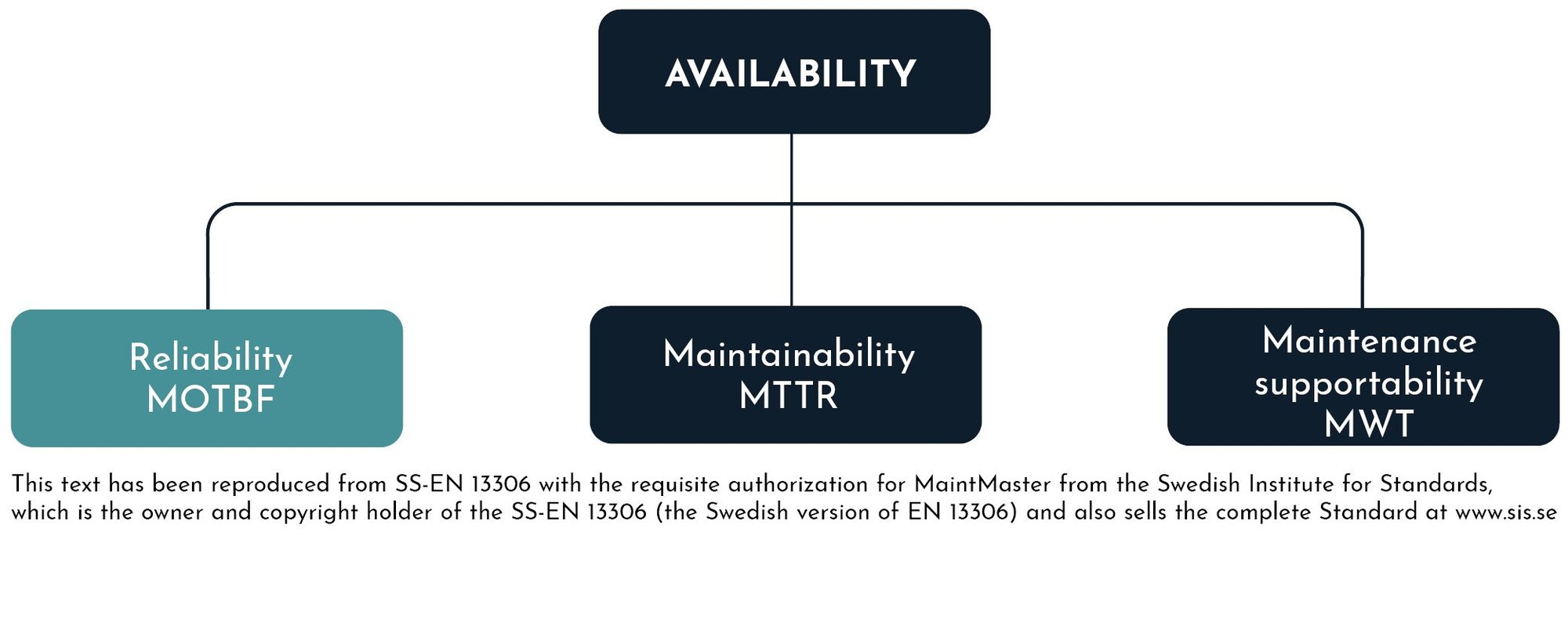

Goals & KPIs: Reliability

The ability of a unit to perform the required function under given conditions during a given time interval.

A measure of reliability is the Mean Operating Time Between Failures (MOTBF). That is the time that elapses between the last corrective actions for a failure until the next failure occurs. Through regular condition checks of machines and planned actions to correct deviations, the time between failures can be increased, leading to higher functional safety.

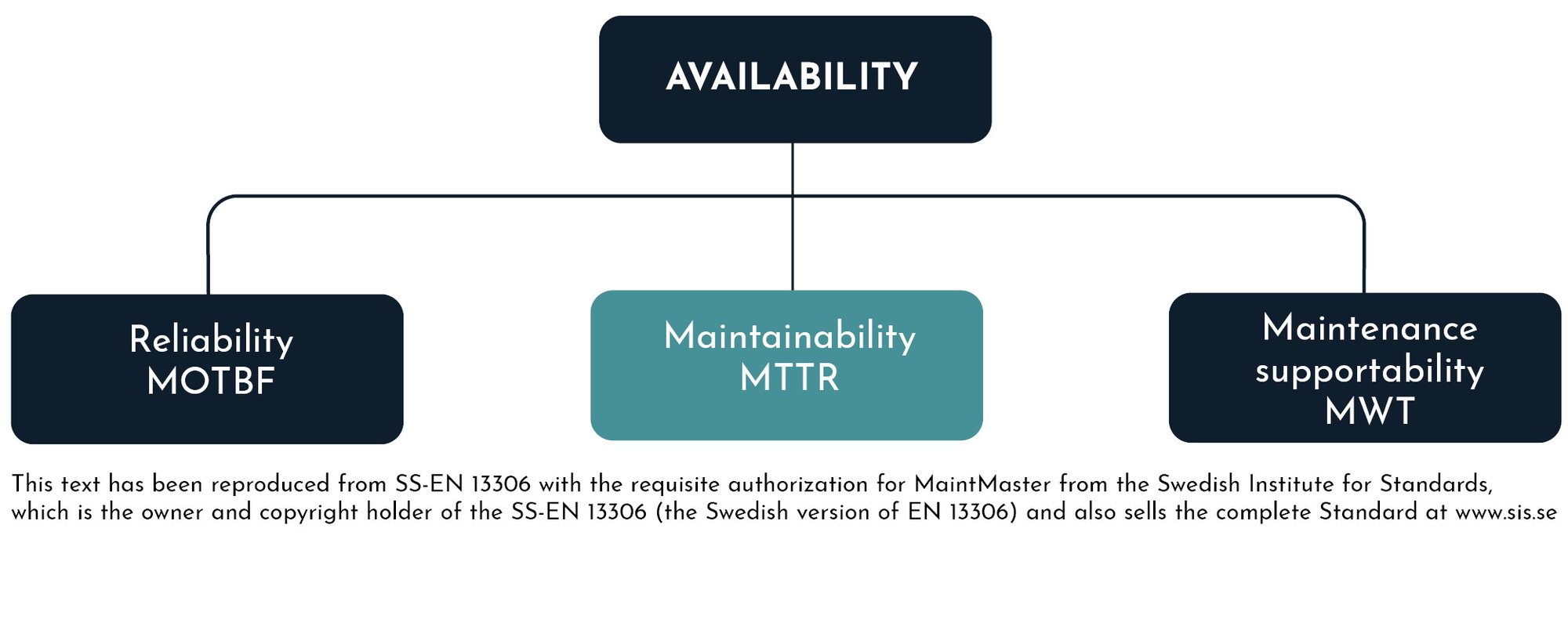

Goals & KPIs: Maintainability

The ability of a unit, under given conditions of use, to be maintained in or restored to a condition that enables it to perform the required function, where maintenance is carried out under given conditions and using established procedures and resources.

An example of a key performance indicator to measure Maintainability is Mean Time to Restore (MTTR). MTTR is the mean time to resolve a fault and one way to influence this can be for maintenance to be involved in the design of a new asset to ensure that wear parts are easy to replace and that the necessary resources such as lifting equipment are available in the design of a machine.

Goals & KPIs: Maintenance supportability

The ability of a maintenance organisation to provide the right maintenance support at the required location so that the required maintenance activity is performed when required.

Maintenance supportability describes the ability of the maintenance organisation to provide the resources required to perform maintenance activities, and can be described as the Mean Waiting Time (MWT) for a maintenance task. Some things that lead to increased Maintenance supportability are the planning of maintenance activities and ensuring the availability and high quality of technical documentation.

Goals & KPIs: Availability

Reliability and maintainability take into account the ability of the technical system to meet dependability, while maintenance supportability describes the ability of the maintenance organisation to effectively address failures. These three factors are in turn determined by a number of sub-factors and maintenance activities.

Maintmaster Maintenance Manual

This free manual can be used as a practical guide and support in the daily maintenance work and as part of the introductory material for newly employed personnel.

In this manual, you will learn:

How to create vision, strategy and policies for your maintenance team

How to build a maintenance team

Which KPIs to use and how to set them up

How to base your work on the EN Maintenance Standard

And a lot more…

- 1. Maintenance according to Euorpean standards

- 2. Maintenance Vision, Strategy & Policy

- 3. Maintenance standard

- 4. Preventive Maintenance

- 5. Corrective Maintenance

- 6. Improvement Maintenance

- 7. Modification

- 8. Case Management

- 9. Organisation

- 10. Finance

- 11. Goals & Key Performance Indiscators (KPIS)

- 12. Implementation in MaintMaster

- 13. Planning & Scheduling

- 14. Spare Parts Management

- 15. LEAN - 5S

- 16. Systematic Work Environment Management

- 17. Learn the basics of a CMMS